Would there be any demand for an STC allowing the installation of inspection plugs into the top of a Lyco crankcase?

They could be quite small. 1cm diameter would be enough.

It would make a dramatic difference to the ability to inspect an engine.

They could be installed only by engine shop, because the crankcases would need to be split to remove the swarf from drilling and tapping the holes, though in theory any A&P could do it in the US.

The Lyco camshaft lobe that fails from what I have seen, tends to be the one that drives 2 push rods as it is works twice as hard.

Another simple check to see if your camshaft is working correctly and giving enough valve movement is, to remove the rocker covers and rotate the engine by hand and measure the movement of the valve springs. Not a scientific method really, but it will give you a good indication that things are working properly. It obviously doesn’t tell you if you have any corrosion on the camshaft.

Peter wrote:

Would there be any demand for an STC allowing the installation of inspection plugs into the top of a Lyco crankcase?

The stress concentration factor for a round hole is 2.0, and that effect on fatigue life is hard to assess without testing. Obviously a better way to do it would be to change the casting.

Measuring valve lift is easy and while not accurate enough to assess the exact moment a cam goes beyond service limits, it’s likely good enough to determine whether an unsafe loss of power exists.

To do it properly, the casting would need to be thickened around the hole. Nobody is going to be doing STCd replacement crankcases; this is obvious from the low take-up of roller tappets at overhauls, which need new crankcases too.

How could one do fatigue testing?

@pilot_dar may know more.

I was thinking of inspection for corrosion. The valve lift is certainly easy enough to measure but you will get the same lift with a heavily corroded camshaft etc – so long as the engine has not been run very much in that condition

Interesting thread.

Another way to inspect the cams would be by removing the prop and the plug, and then insert your favorite borescope… you might have guessed, it only works with hollow shafts

How would that reach the camshaft?

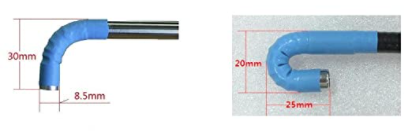

Normally, to see something useful with a borescope, you need to get fairly close, say 2-3cm, and this way the distance will be about 30cm – assuming the borescope has the “bendy” end, like say the Vividia

You could see a lot of other stuff, however, especially the conrods (any rust → scrap).

It ain’t my idea, and I have yet to try it out… more details here: Van’s Airforce Net

I accidentally discovered the method posted above by @Dan.

There are two configurations of crankshaft plugs. On FP you have no rear plug (or a rear plug with a hole pierced in it) but you have a plug in the front. For CS you have a plug in the rear, so this method won’t work on a CS prop engine as the rear plug is not really removable without tearing down the engine.

The front plug takes 30 seconds to remove with a punch, and a replacement is about £3. I removed mine to check if my engine has a cross tube in the crank for a CS prop oil feed (it does! YAY!) and realised I should put a scope down there. I put a bag in the crank to not get the scope too oily.

As you can see my cam is pitted but the followers don’t look ruined like some of the pictures I’ve seen. Undecided on what to do next (other than keep flying it and monitor).

The proof is in the pudding  Thanks for that and for the vid @IO390.

Thanks for that and for the vid @IO390.

Undecided on what to do next (other than keep flying it and monitor).

Camshafts can be reground, but the problem is evident, one needs to split the case open, which in return means overhauling the engine, which means money being spent…

Keep flying and monitor would be my favorite, oil analysis at each oil change will point to any deterioration of cams… fingers crossed

Yeah, those lobes ain’t looking good. Surely you are using W80 or W100 oil +CG (not 15W50).

If so, I cannot disagree with your course of action unless the engine is “timed out” whatever that means. 50-hour filter inspection (you have a filter and know how to properly inspect for debris?) , suction screen inspection and oil analysis should be enough to catch any accelerated wear. If not flying min 10-hrs/mo and at least every 15 days, add an oil analysis every 25 hrs (low-cost insurance) and follow trends. Measure also valve lift every 50 hrs to be sure and keep track of the record.

Look at EGT trends from flight to flight (you have multi-cyl EGT, right?) and if you see a variation, suspect valve lift and measure.

A lot of engines are flying in that condition and you would never know until the time for OH.

With this trend-monitoring system implemented , as soon as you see something out of the ordinary, time to look further again!