I will get the guy’s 337 if/when I do my backup alternator. There might be something useful there – even just the fact that he fitted this B&C alternator to a TB20 is useful.

What he did was a massive money-throwing exercise, but he also had competent people who knew the FAA process. OTOH using the DER / 8110 route totally avoids any interaction with the FAA/FSDO system and avoids the risk of discovering a knucklehead at your local FSDO…

Due to Lyco’s blank drive shaft in my engine, it will have to be done at overhaul time, so I have plenty of time.

Thanks for that lead.

I will be installing an exchange engine this winter and will get this whole business sorted. Watch this space…

Mine is at 1800hrs actual airborne time so it doesn’t need doing now, but I have a very rare opportunity to get a first-run-core 2k-hr engine rebuilt by Barrett Precision in Tulsa, OK, so their current 14 week overhaul time becomes just 1-2 weeks (they will overhaul and return all my existing accessories). The engine is ex Israel Air Force who sold their TB20 engine stock to the USA recently. This one was never used for training; it was used for VIP and military transport and some aerobatics (!) and is in grade A internal condition, with complete logbooks. They had five of them and I got the last one. They still have two IO540-C4B5 left (twin magneto) in case anybody is interested. The exchange cost is similar to the OH cost – in the region of $35k plus transport.

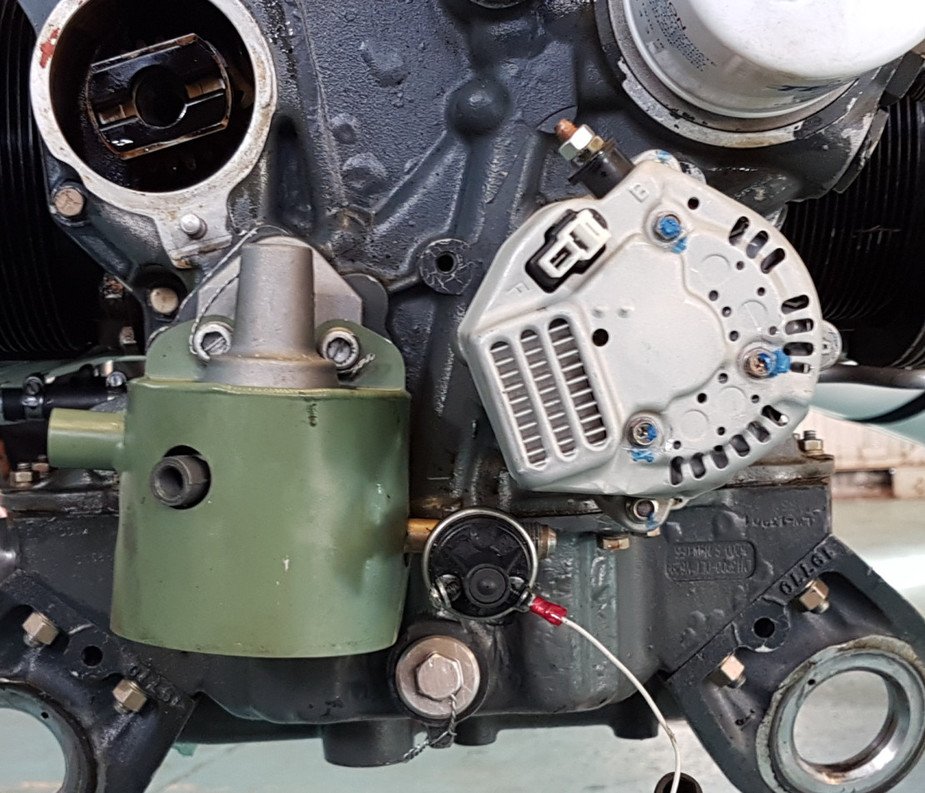

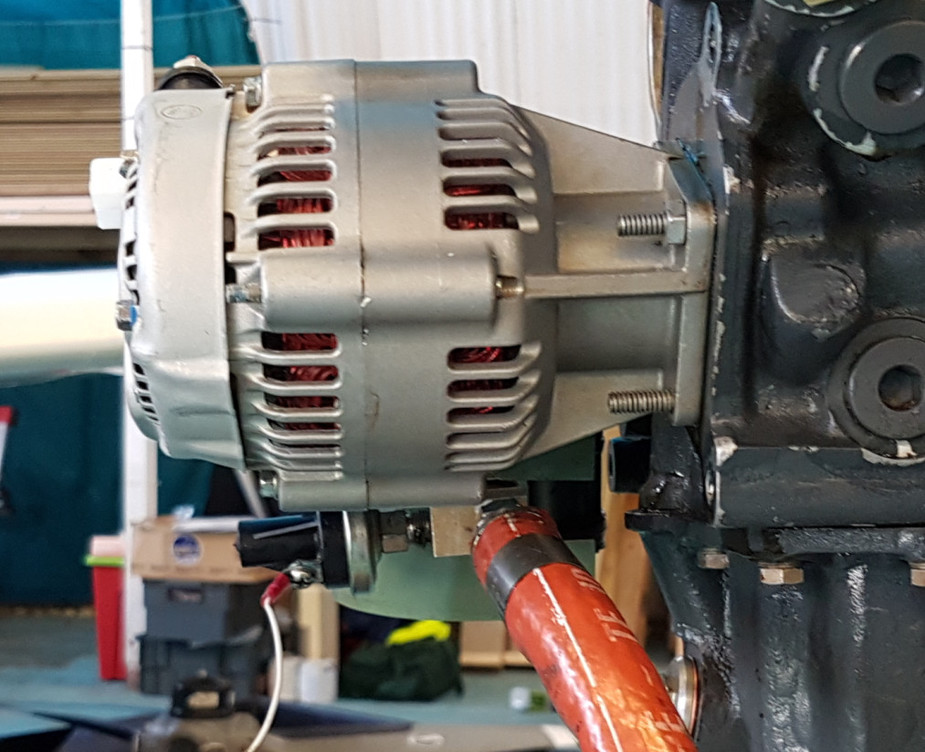

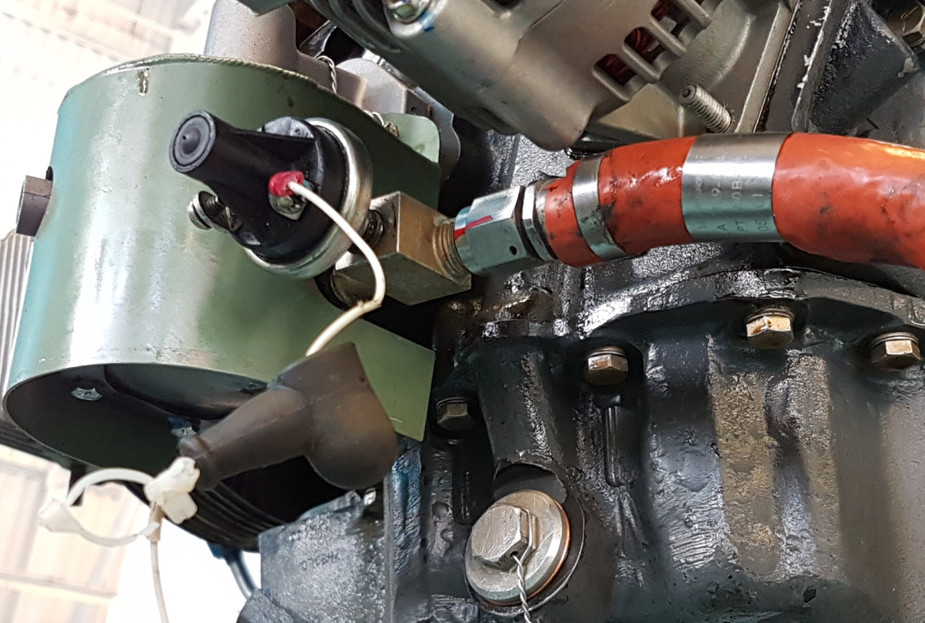

Some pics of the B&C backup alternator mounted temporarily in place (on an engine about to be shipped to the USA for exchange) to see how it fits

This shows the fuel pressure switch, whose mounting needs to be rotated slightly to miss the alternator

Jesse wrote:

Wonder if you have tested it, and what output you have measured.

Did you check this?

No, the above is a mockup, as stated. When the engine comes back I will start off a Field Approval process for the alternator, via a contact I have in the USA. There is no B&C STC for the TB20 and the 3rd option is a DER 8110 but I don’t currently have any reasonable DER contacts.

IMHO it could be done as a Minor Alteration too but I am not too bothered.

It doesn’t matter about the output being below spec at low RPM. It merely needs to deliver the specced 20A or so at cruise i.e. 2300+ RPM. My entire plane draws about 20A if I turn off the outside lights.

Peter,

Do I understand correctly that you accept to abandon the core that served you well during the last 2000 hours flight, in favor of an unknown military ex- aircraft engine ?

I thought you would have wanted to keep yours, but obviously am wrong.

Dealing with alternator: do you really feel the need to undergo all the process to improve redunduncy ? Or is it be linked to with the TKS upgrade ?

I wish you the best in the process !!

Briefly, I have an opportunity of a first-run exchange engine (whose core was accompanied by detailed logbooks which have none of the usual reasons to be forged) and a 2 week turnaround, versus a 14 week turnaround to overhaul my own engine. Indeed, I would not touch the typical 6000-hour+ exchange engine which probably has a dodgy history anyway, since most people overhaul their own engine until they can’t.

The backup alternator is for redundancy, yes. The TB20 has multiple buses but only one alternator and one battery. With this, if you get an alternator failure, you can continue the flight to destination. Without it, you need to land urgently, almost regardless of the weather below.

The TKS stuff is a separate project which shows no sign of arriving… Maybe I will be able to arrange a nice warm hangar in the summer and put 2 people on it and do it in a few weeks.

Thanks

Peter wrote:

It doesn’t matter about the output being below spec at low RPM. It merely needs to deliver the specced 20A or so at cruise

Mmmm, the manufacturer specifies an output at a certain RPM, The ones I have tested always underdeliverd significantly, e.g. no 20A at cruise. For sure at lower RPM you will always have lower output.

That was why I wondered if you had a change to test yours.

Did you contact B&C with your test data, Jesse?

Jesse wrote:

Mmmm, the manufacturer specifies an output at a certain RPM, The ones I have tested always underdeliverd significantly, e.g. no 20A at cruise. For sure at lower RPM you will always have lower output.

Why would this installation be any different than the Factory B&C installations on Mooney Ovations or any of the dozen or so STCs ?