So, today I got the offer from Daher.

I got actually 2 options. The “initial” verdict is 65250 EUR which contains the whole aft fuselage using my levator and fin and the 9th bracket. Paint and deliver to the paint shop and an additional 170 hours of competition for the return flight. Engine, wing empennage installation, settings, testing, re-adjusting after test and the Form 1.

The job itself is 124 hours +170 the completion. There is a light version when I send only the fuselage, and I assemble it at my hangar….

There is always something to work for :)

I would try to carry out the work on site. You probably need a repair engineering either by Daher or another part 21 company. Then have someone do the metal work where the aircraft is located and then fly it to some place it can get painted. I did this with a PA46 with wing damage years ago. Disassembling the entire aircraft is a huge additional can of worms.

Replacing the aft section of the monocoque fuselage (there is no structure in that section of the fuselage of a TB other than two stringers on the floor) without production jigs is not likely to be possible IMO.

I hate to say this, but with all that hassle and money involved, would it not make more sense to sell the airplane for parting out and get a new one?

Replacing the aft section of the monocoque fuselage (there is no structure in that section of the fuselage of a TB other than two stringers on the floor) without production jigs is not likely to be possible IMO.

I agree; you would end up with yet another plane which needs aileron trim tabs bent one up and one down, the rudder trim off to one side, and flies 10kt slower

Look at the “mystery of TB20 full-TKS installations dropping 7kt+ off the normal speed”. It doesn’t take much.

You had (have) one of the nicest TB20s in existence; I would fix it properly

I hate to say this, but with all that hassle and money involved, would it not make more sense to sell the airplane for parting out and get a new one?

Parting out takes for ever. I have seen it done; one guy was parting out a low time (~400hrs) TB10 and the thing sat there for years. In the end, when he was down to a small pile, he offered me the whole lot for free just to see the end of it

And there are no new ones; not since 2002. The ones you see are in various conditions and only a few are really nice.

Also Zsolt spent a load of time and money on upgrades such as this. Very few avionics shops are capable of doing big jobs like that correctly.

Typically a repair like this starts with building a jig , if currently unavailable, using an undamaged aircraft.

Hi, my fellow TB friends!

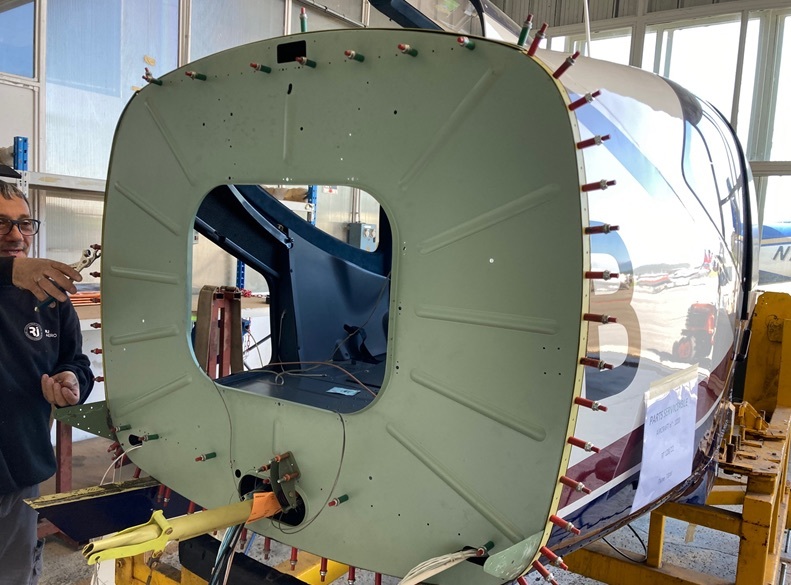

I want to give you an update about my TB20GT SN2220 repair history. The final decision was to repair it in Tarbes, accepting the complete repair offer from the factory. It means I disassemble it, put everything on a trailer (big, closed truck) and transported it to Tarbes. There,

- they replace the rear fuselage part between Frame 6 and the tail, saving the frame 9 and the frame 6.

- spraying the whole fuselage with the original paint

- assembling the aircraft

- performing 6Month inspection

-testing and releasing it …and I fly it back to Budapest. The whole process estimated six weeks, 376 labour hours ( 100 EUR/hour) and a significant number of EURO :)

The aircraft arrived on the 29th of March in Tarbes, and the first photo arrived on the 2nd of April. The work went flawless until they found a dent on the frame Nr 6 (rear wall of the baggage compartment). The decision to change it after the part is manufactured. They calculated 35 labour and 10 engineering hours on top of part cost. A high additional cost is the aft cabin fan, which was also broken when the hangar hit the tail. Now, I have paid the 50% of the charges, which means the aircraft will be assembled in two weeks. The factory expected 170 labour hours for it—wings on, engine and prop installation, electronic, AP cables and system testing. The final result is a brutal number; I don’t want to see it :) They promised me a nice shiny new aircraft. I asked them to be careful with the calculation, since I pay it from my savings :( . The representative is a kind person, and he keeps me in the loop always.

Brilliant to see this coming along, and great to see that Socata still has the capability to do this repair.

There have been so many stories – some from Socata people – that they no longer have airframe parts, etc.