I think you’re looking at increasing the temperature delta in cycles, which is more likely to cause greater condensation than you started with.

Additionally you’re ‘pulling’ whatever moisture is present in the air and pushing it around regardless of the possibility the air inside the aircraft/engine is already slightly lower.

No expert here, but just my take on it.

Inside the aircraft I use 3 large Unibond Aero360 units, and they really do make a difference.

The small units with granules are significantly less effective. I sit them so they cannot spill their solution, and leave them in an airtight box when I go flying.

I started creating an engine unit with dried forced air but the reality is, it’s another thing to deal with, and It’s kinda at the point of ‘the straw that brakes the camel’s back’

I tend to think that Pete is right here. Unless I’m missing something your solution would do more harm than good.

To answer your question, my device is bottom end only (i.e. mainly cam shaft). Dry air flows into the crank case via the dipstick receptacle and leaves it via the breather. To force air into the top end, you would have to block the breather, including the ‘ice hole‘ in order to pressurize the crank case. The ‘ice hole‘ might be hard to get to, depending on aircraft type. Anyway, it would only work for cylinders that had one valve open when the engine came to a rest.

Would pushing the air pre-dried by the Peltier element through old-school silca gel allow you to get better performance? Would it be worth it? If I understand correctly, the current limit is at about 11C and 66% ambient, which I would think is a bit too high.

Or, maybe, two pumps, one via the Peltier, and once that stops performing, the other one, through silca, kicks in.

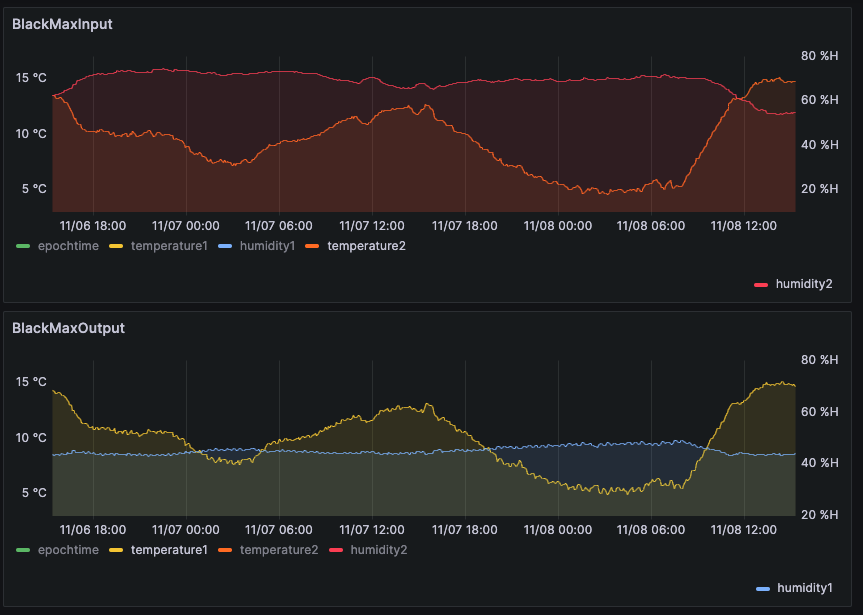

Here are some graphs of my humidity and temperature sensors before and after the “black max”:

Generally it keeps the humidity between 40 and 50%.

I set this monitoring up as I’m also testing some comparison methods like silica beads and silica kitty litter. Also testing the best way to move the air through the beads. Nothing conclusive yet, except a lot of “wrong ways” to do it.

I like the black max but accept that it’s kind of expensive, and annoying when it stops and I have to wait a week or so for replacement parts.

I certainly don’t like drying beads in the oven, and the wife likes it even less than I do.

Yeah I guess my ideas need some refinement :)

So the black max (as per their manual) feeds into the breather tube and the oil cap stays on. Meaning the air flows out through exhaust or intake system (I guess depends how the valves are positioned for a particular cylinder). That makes lots of sense to me. Wondering why not everyone does it like this (seems most DYI users feed dry air through the oil filler and don’t plug breather tube)

So let’s say I go with the silica DYI solution. Maybe I can dry the silica beads periodically with my boot dryer. I will research this some more.

HBadger wrote:

Maybe I can dry the silica beads periodically

A good method is to put them in the oven, maybe tell your wife beforehand, for like 40 minutes at 120°C, no more. Depending the brand, u can get the max drying temp from their instructions.

There are a few aircraft using them silica stuff on my field, and I also used it for a few years before switching to the BlackMax, and now to my deluxe heated hangar

There have been plenty of people experimenting with DIY driers, plenty of threads on VAF, but better use your usual search tool than VAFs own.

I did research it in the mean time and it seems while the oven method of course works, you could instead go lower temperature and just dry it longer. I will run an experiment and see what happens :)

Hello Terbang,

Not being an expert at all, but what if you put a second box on the hot side of the peltier and have your pre-dried air going through this hot element. It may get into the engine a bit hotter but with a lower rel moisture. Actually it won’t reduce the quantity of water in, so could just push the water farther in the engine, but on a regular long run period, I think it may help, in addition to keep the engine warmer.

Would pushing the air pre-dried by the Peltier element through old-school silca gel allow you to get better performance? Would it be worth it?

It certainly would. According to reports by others and my (admittedly not very diligent) measurements silica gel alone works quite well. However, I wanted a solution that didn’t require any maintenance. I did the whole project mostly for fun. If I had used the time I spent on it for drying silica gel, I would be done for life 🤣

Hello Terbang,

Not being an expert at all, but what if you put a second box on the hot side of the peltier and have your pre-dried air going through this hot element. It may get into the engine a bit hotter but with a lower rel moisture. Actually it won’t reduce the quantity of water in, so could just push the water farther in the engine, but on a regular long run period, I think it may help, in addition to keep the engine warmer.

Hi Greg,

not an expert on this either, but I don’t think it would work. As you say, it would lower the relative humidity of the air but wouldn’t change the dew point (i.e. the absolute humidity). I think, the air would be at ambient temperature again by the time it reaches the engine. In fact, the pump is behind the cooler in my setup und it warms up the air quite a bit if measured directly in its container. However, this effect is already mostly gone in the little “measuring chamber“ food container.