@tmo

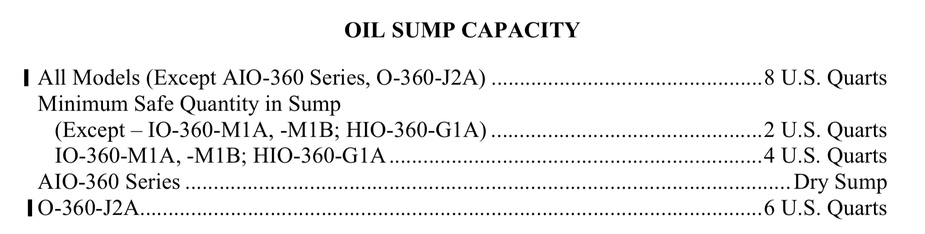

A read of LYCOMING OPERATOR’S MANUAL SECTION 3 O-360 AND ASSOCIATED MODELS, SECTION 3 OPERATING INSTRUCTIONS states the following:

2 US Quarts being the minimum for most models of the ubiquitous O-360 Lyco. And nobody should fill to the max, 6 in the Summer and 5 in the Winter works perfect…

The burping procedure is also useful for: a) checking for any awkward engine noises

Don’t those Rotax thingies always make awkward noises

2 qts is also for the IO540 but you need to be straight and level, or at least no sideways G or climb or descent

Is it correct the recommended capacity is based on the type endurance, the minimum and assumption of one quart/hour consumption. The framework may be a holdover from radial engines?

In the Continental TSIO-360 TCDS (E9CE) I see no mention of “minimum safe quantity”, the closest I can get is capacity of 8qt with 5qt usable at 26deg nose up / 18deg nose down. Is it really not there, or am I doing it wrong?

The mentioned TCDS is here: https://drs.faa.gov/browse/excelExternalWindow/B548EBE7CD368BFE862585CA005EA1CD.0001 and I believe it does not change, as weird as it looks.

I have been told that this burp noise and prop action is to ensure that remains of the oil in the low end of the engine goes back to the dry sump, and it’s due to the tank due to dry sump kind of engine, with the fact that return tank is higher than low part of the engine. That’s a bit of design flaw because many car rengine (including old ones) doesn’t need that for oil check, but it may be also due to the low quantity of oil in the tank, where a small quantity will make a difference. With 8 liters, it wouldn’t make a few cl a notable change. Here it’s 2.5 to 3 liters, very few…

Talking about technique, it’s not so much about the speed of turning the propeller but about turning it and holding it whilst a piston is at TDC for at least a couple of seconds in order to build up the pressure. Compressed air at the top of the cylinder will then leak pass the rings thus pressurizing the crankcase, forcing the oil back to the tank.

Follow that technique and it’s relatively quick. However if the tank is mounted higher than normal (like on my aircraft) then the amount of blades turned can be higher, especially when the engine is cold, as you’re fighting a cold thick oil combined with gravity.

Dan wrote:

Don’t those Rotax thingies always make awkward noises

Only when you shut them down.

Why bother the average Rotax uses an egg cup of oil every 50 hour check. Check it after you have flown it. Also if there is a drop of oil at the very bottom of the dipstick in will be in the correct range after burping. I don’t like touch propellers.

johnh wrote:

And the way you make it work is by turning the prop through about 20 blades

Only one thing to say to this: RTFM !