It seems to me that if you allow dirt to accumulate on the shiny steel surface, it will bugger up the seal and eventually the gas will escape, and then you are looking at an expensive overhaul.

Now I wipe the stuff off before flying. So far mine have lasted 14 years, with negligible leakage.

I’ve had this happen (gas bugger off) on a club PA28 in the most inconvenient place (Venice Lido). It made for a very expensive repair (1300 € total IIRC) for a .50 € part (O-ring) and a lot of inconvenience. Don’t know if this was caused by dirt though, but it is well conceivable.

Standard practice on daily checks on airliners.

I’ve never seen anyone do this in GA.

Normal on PA46s.

The reason that the things never get cleaned in GA is most pilots don’t want to get their hands covered in MIL5606.

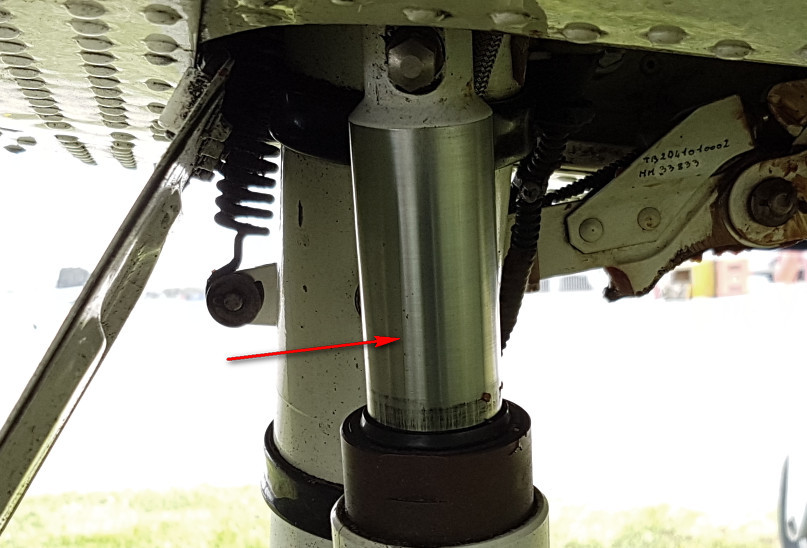

Almost all of these units have a scraper that cleans most of the dirt from the sliding part of the strut to keep the oil/gas seal from getting too much dirt on it.

These things are quite reliable and usually give a lot of warning before failing completely with small leaks being the first indication of trouble ahead.

The problem that RWY20 had was most likely a dry seal " rolling " in the seal carrier, my first move would have been to check the oil level and then jack the aircraft up to the normal leg extension position and then put some air in the leg, if there was any more life in the seal that would find it.

Airliner legs get cleaned each night due to the financial cost of a failure, they also cary spare seals in the legs so the whole sliding part of the leg does not have to be removed to change a faulty seal ( you just need to support the aircraft and drop the bottom gland nut to get at the spare seals).

You can increase the life of the seals by keeping the legs clean and making sure that an air/oil service is carried out at least at each annual check. It is vital that this is done IAW the aircraft maintenance manual, the procedures on American aircraft are much the same but differ on other types, Robin use the same legs on all the DR400 series but the servicing procedure differs between models……….. I guess this is why you almost never see a Robin sitting correctly on the ground.

Same as A and C says. Done every day (should be) on the daily check on large aircraft. Done as part of the maintenance check on the aircraft I work on now. I did it when I worked on my own customers aircraft and when I worked for a large group of flying schools. Buy yourself a can of Aeroshell fluid 41 and you it yourselves.

146fixer wrote:

Buy yourself a can of Aeroshell fluid 41 and you it yourselves.

Back in the days when I had shares in aeroplanes, our maintenance company filled me a marmelade jar with that stuff. It was their recommendation to clean and lightly lubricate the gear struts (and also the hydraulic jacks of the retraction mechanism) as often as possible. But outside maintenance shops I never saw anyone doing that.

Perhaps we are not looking carefully enough at this problem and should also be looking at what we are putting inside the landing gear shock struts.

Shell are now offering specialist fluids for landing gear shock struts the one most likely to be of use at this end of the market is Aeroshell LGF. This is basicly Aeroshell 41 plus additives for high load situations found in landing gear applications, it is widely approved by commercial aviation manufacturers ( Boeing, Airbus, Lockheed etc).

I did ask Robin about this but they said they did not have the time to look into approving Aeroshell LGF but with Shell saying it is compatible (and can be mixed) with Aeroshell 41 I can’t see any problems with using it unless you are a lawyer.

@Peter. What do you use to wash this stuff off? Thank you!