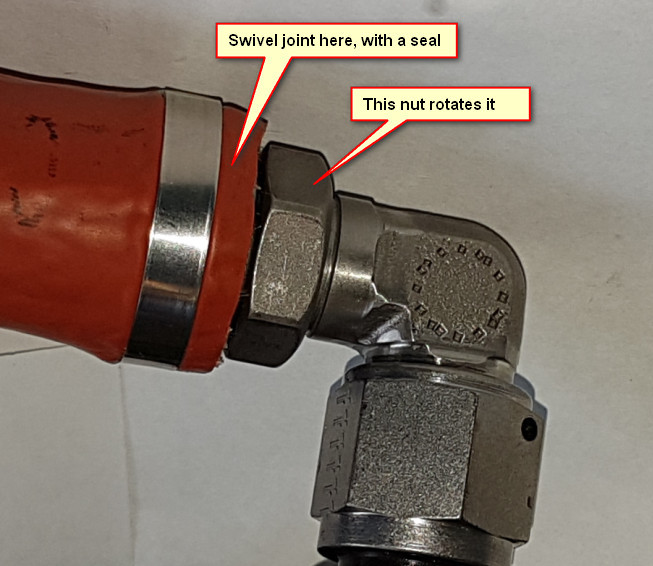

I saw this on another plane (a turboprop) the other day

It is apparently used in the military quite a lot. The swivel joint is never tightened – no need to do so as it is quite hard to rotate anyway. You can just about turn it by hand.

It has two advantages:

I have never seen this used in low-end GA. Apparently it doesn’t cost anything significant, but most hose shops can’t do it. The seal in there must be pretty good because these hoses are all pressure tested at about 1500psi.

Bonus points for knowing what the little round hole in the lower nut does

That’s very interesting, Vic – thanks for posting that.

The curious thing is where would the o-ring be? You can’t drive the threaded portion past it because that would damage it.

I thought the little hole in the nut – a common feature of hydraulic hoses – is to ensure that if someone unscrewed the hose with pressure inside, any pressure escapes (through the hole) while the fitting still has several threads holding it together. Well it may have that function but – I have just looked at some hoses – you are right; there is a pin driven in there.

That wasn’t my hose; I saw it on another aircraft. But I think I know where it was made, so will try to find out.