Conventional avionics:

Glass (this is a G1000 in a DA40):

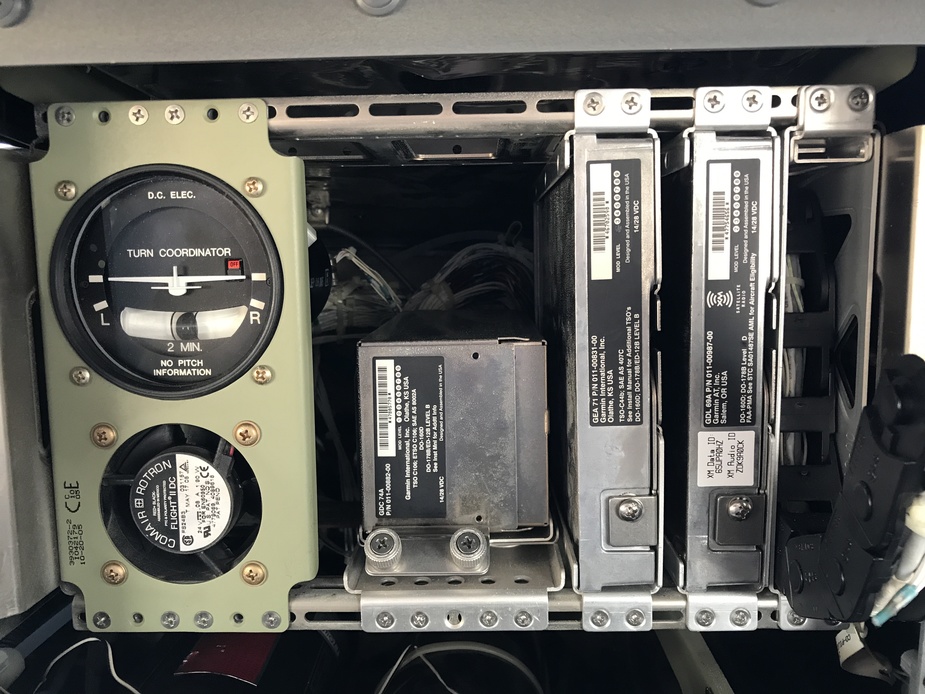

A bit more clumsy behind, and with a lot of deported units which implies loads of harness / cabling

Of course the G1000 pic only shows the cradle of the displays and not the LRU’s and racks to drive them. These are not that bulky though and there is another advantage for the aircraft designer: they can be placed anywhere, which comes in handy for Mass & Balance and accessibility considerations. In the DA42 the LRU’s are placed underneath the rear baggage floor, immediately accessible.

I am looking at a weight saving of around 50Lb with a G500 system over the King IFR setup, the remote boxes also are helping with C Of G issues as they can be placed more advantageously.

The system with remotely located units is easier to assemble because (in production) you can produce a uniform wiring harness. One can do it too for individual units but it is more messy, and historically the config used to vary more. Also general access should be a lot easier. On a lot of planes, working behind the panel is a pig of a job.

That hidden turn coordinator is quite funny

Peter wrote:

That hidden turn coordinator is quite funny

Yes, this is a strong will to hide the things of the past :-)

On my aircraft, it feeds the AP (KAP140), making the loss of the G1000 a non-event (from the AP stand point).