In what way is the flathead running at half the rpm of the Rotax but putting out twice the torque more efficient? Hang a 2:1 reduction gear in the Rotax and you have exactly the same thing when you stick in on a Dyno.

I can see the advantages of the flathead though. It should be lighter, less complex, cheaper and theoretically more reliable.

Joe_90 wrote:

In what way is the flathead running at half the rpm of the Rotax but putting out twice the torque more efficient? Hang a 2:1 reduction gear in the Rotax and you have exactly the same thing when you stick in on a Dyno.

I can’t say for the D-Motor, but you do not have ‘exactly the same thing’ when you put the Rotax and a Lycoming or Continental of the same peak power rating on the dyno. That’s why you have a constant speed prop on the Rotax to haul around a Cessna 150 equipped under the French STC.

A lower rpm engine making the same power with displacement and torque very often has a wider power band because it doesn’t utilize resonant intake and exhaust tuning like a higher rpm engine. You pay for this with weight, unless something else is done to cut weight. Again, it depends on the specific engines, for example a (relatively heavy) 4 valve per cylinder OHV engine can breathe at high RPM without so much resonant tuning. Certainly a large displacement, low rpm, potentially light-ish flathead engine is unlikely to have much power boost from resonant tuning, and therefore will be less likely to have torque drop off quickly when moving away from peak power RPM.

Friction losses increase with RPM but the exact comparison depends on the engines being compared, and unlike many such low vs. high RPM comparisons these engines have the same number of cylinders (more smaller cylinders otherwise means more friction). In this instance fuel efficiency is regardless not the objective of the flat head, it is a clear downside, but weight may be lower and perhaps lower RPM operation may help offset intrinsically lower flathead efficiency.

In what way is the flathead running at half the rpm of the Rotax but putting out twice the torque more efficient?

The most efficient engine runs at low revs and has only one cylinder

Peter wrote:

The most efficient engine runs at low revs and has only one cylinder

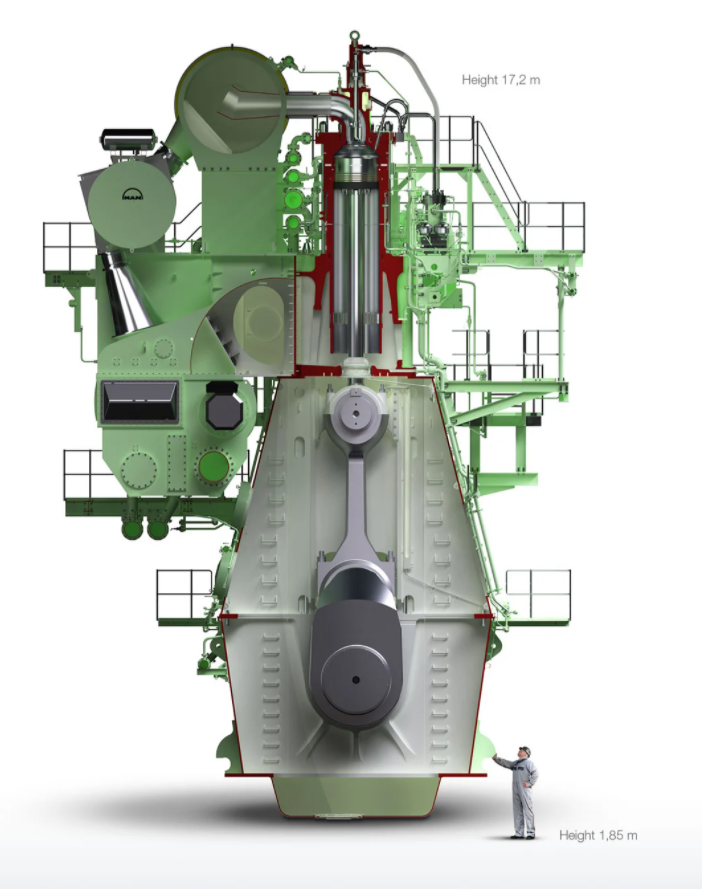

Certainly not. The most efficient combustion engines are huge marine 2 stroke diesels with an abundance of cylinders. They do run at very low revs, about 100 rpm. This is an example, 92k HP:

Yes; they have more cylinders because one cylinder would be too clumsy, and would vibrate too much

Same argument for propellers. The most efficient propeller is a slowly rotating single-blade one

Music for helicopter nerds  (sometimes defined as noise

(sometimes defined as noise  )

)

I don’t understand why the number of cylinders should make any difference, ten identical cylinders tied together on a single crankshaft should simply deliver ten times the power, all other things being equal, with minor differences only from sharing some components (bearings and the cam drive)…

LeSving wrote:

The higher the pitch, the more attenuated it becomes at a distance. I really don’t think the RPM of a Rotax (4-5000) vs direct drive (2-3000) is very much difference

I think there are also other things involved: a similar powered Rotax is a lot quieter than a similar powered Lycoming plane when they are still pretty close to you.

With the direct drive engines, all the sound energy is concentrated in all the same place or at a harmonic. For instance, for a Lycoming powered plane with a 2 blade prop, you’ve got a strong sound at 2 × RPM, and a strong sound from the power pulses at 4 × RPM (the 2nd harmonic of the prop noise). The prop in turn will also be making quite a bit of noise at its 2nd harmonic, so you get an awful lot of sound energy concentrated into small frequency bands.

With Rotax, you’ve got a prop reduction unit, and not only is the prop turning slower (and typically it’s shorter and 3 bladed, so the tip speeds are much lower and the prop noise less), the note from the prop doesn’t share the engine’s fundamental frequency at all or any of its harmonics, so the sound energy is spread over a much greater spectrum, so this helps make a Rotax plane seem much quieter even if it’s close to you.

Cobalt wrote:

I don’t understand why the number of cylinders should make any difference, ten identical cylinders tied together on a single crankshaft should simply deliver ten times the power, all other things being equal, with minor differences only from sharing some components (bearings and the cam drive)…

Efficiency and power density are generally in opposition, when considering the number of cylinders. As an extreme example, compare the fuel economy of a 2V/cylinder OHV Harley twin and a 1960s six cylinder 250 cc Honda GP motorcycle engine and you’ll find the Harley has much, much better fuel efficiency even while making dramatically less power per liter displacement. The reason is less friction losses.

I really like the look of this engine but I’ve heard that it doesn’t produce as much thrust as a 912 and that engines longevity is legendary.

To my knowledge the D-motor has been fitted to skyrangers, C42’s and EV97 eurostars and in all cases was the replaced with the 912 as that offered better performance.