Something recently reminded me of the more than few occasions in different aircraft i have arrived to find a breaker popped often one of the alternators but not always. I am happy to reset it once and that has pretty much always worked. On the other hand a cant recall coming back to an aircraft which i had left with a popped breaker. The last occasion which reminded me was a SR22 in the states.

The only time I will accept a popped breaker when taking over an aircraft is after maintenance. The mechanics sometimes pull brakers of circuits which they don’t want to be alive while working on the plane. If no maintenance was scheduled or known to me I either call one of the mechanics and ask if he knows anything about it or the pilot/instructor who flew the aircraft before me. Without a satisfying answer I will not fly with such an aircraft, especially if vital (for instrument flying at least) circuits are involved.

The circuit breaker protects the wire between the buss bar, and the circuit load. If the breaker has popped, it’s fair to suspect that the load already has had a defect. If a load has had a defect, and you the pilot don’t understand why, best to leave it alone. If you’re feeling daring, and circumstances would seem to allow, reset it once, and see what happens = monitor the breaker, the load, and the ammeter.

A part of being competent on type means that you understand the circuits of the aircraft, and can make a good decision about what systems must be operable for the intended flight. Maybe it’s intense night IFR, so all of them, maybe it’s an uncontrolled airspace flight on a nice VMC day, so perhaps none. I have certainly flown aircraft home electrics off, because that type was suited to fly that way, and I did not require any electrical systems to be operating.

Understanding your electrical system, and it’s loads can be very useful in the case of partial electrical failure. You might choose to start pulling breakers to isolate circuits, to preserve what little electricity the aircraft has or is making. I’ve been in that situation many times.

One thing I would add to the above: the CBs used in light GA are not 100% reliable. They sometimes pop at a much lower current than rated. This is probably as a result of long term damage via internal heating. If you run a 10A CB at 7A then it should not pop but it will get quite warm inside, and this degrades the mechanism, especially combined with humidity.

So sometimes the CB itself is duff.

Of course a duff CB, or a duff circuit after the CB, are both good reasons for getting it fixed before any flying.

There has been much discussion about resetting CBs in flight. I recall seeing some instructions (a specific aircraft) that a CB can be reset once and that’s it. If it pops again then you leave it alone.

Whenever I have a panel apart for rewiring, I will test each CB on my power supply to determine what current opens it. My experience has always been that CB’s will carry 15% to 25% more than their stated current for as much as 30 seconds. I have never seen one open at less than its rated current. I have seen them fail open, though [happily] I have never seen one fail closed!

Several companies I have flown with have SOP’s which state reset once only.

Pilot_DAR wrote:

Several companies I have flown with have SOP’s which state reset once only.

We have no company specific SOPs regarding circuit breakers but are supposed to follow Cessna’s abnormal and emergency checklists. These either say “check circuit breaker” or “reset circuit breaker”. According to our training provider one is not supposed to reset a circuit breaker if “check circuit breaker” is in the checklist. It just tells you why the affected system might not work as desired.

But this is for the in-flight case. When taking over an aeroplane on the ground, I would – as already written – not accept a popped circuit breaker without further inquiries. Otherwise this would just mean to take another pilot’s problem in the air…

Whenever I have a panel apart for rewiring, I will test each CB on my power supply to determine what current opens it. My experience has always been that CB’s will carry 15% to 25% more than their stated current for as much as 30 seconds.

I am impressed

In fact I am amazed the thermal CBs work as “well” as they do, being based on such a primitive heating principle. The trip current must be hugely dependent on the ambient temperature too, which could be say -30C or it could be say +60C due to there being so many “warm” wires behind the CB panel. And if you have a panel full of CBs, each carrying say 50% of rated current, the whole assembly will be pretty warm.

I suppose the right approach is to use thick wires and CBs which are appropriate to the wire thickness rather than the maximum final load.

Pilot_DAR wrote:

My experience has always been that CB’s will carry 15% to 25% more than their stated current for as much as 30 seconds. I have never seen one open at less than its rated current. I have seen them fail open, though [happily] I have never seen one fail closed!

I have done a fair amount of design work for electrical installation and CBs are expected to work that way. Basically, CBs (and fuses) protect against shorts and overloads. A short is serious and should cause an immediate disconnect since there is a risk of fire at the place of the short. Overloads primarily cause damage to the cabling and can be accepted for quite some time before the cables become too hot. The risk is damage to the insulation which will typically happen before temperatures get high enough to start a fire.

When choosing the rating of a particular CB, you take into account both the short-circuit current and the amount of energy (heat) that can be dissipated into the cable during an overload before the insulation is damaged.

There are standards for how fast (or not!) a CB is supposed to trip for various currents.

Of course all this is for terrestrial electrical installations – but the physics should be the same in an aircraft.

Peter wrote:

In fact I am amazed the thermal CBs work as “well” as they do, being based on such a primitive heating principle. The trip current must be hugely dependent on the ambient temperature too, which could be say -30C or it could be say +60C due to there being so many “warm” wires behind the CB panel. And if you have a panel full of CBs, each carrying say 50% of rated current, the whole assembly will be pretty warm.

A CB has two trip mechanisms, a magnetic and a thermal one. The magnetic mechanism is intended to trip the short circuit current. It is very fast and independent of temperature. The thermal mechanism is slower and intended to protect against overloads. As you say, it is affected by ambient temperature, but that is not necessarily a bad thing given that the amount of overload the cabling can accept also depends on the ambient temperature.

I don’t think the little CBs used in GA have any magnetic component. Some big ones may have but I am pretty sure nothing I have in my plane has.

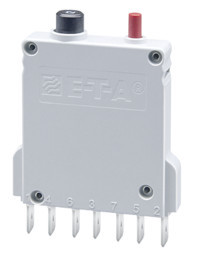

These are definitely thermal only

Even these big ones are thermal

This one is magnetic plus thermal and is similar to the Socata ones used in the centre column as switches

What the actual Socata ones are I don’t know.