Thanks, I’ll ask the owner. The version of the AFM manual has pretty much the same as the checklist items I put above.

Rev. 1 15-Mar-2011

Peter, on the 62 we fly with Alternate Air in visible moisture.

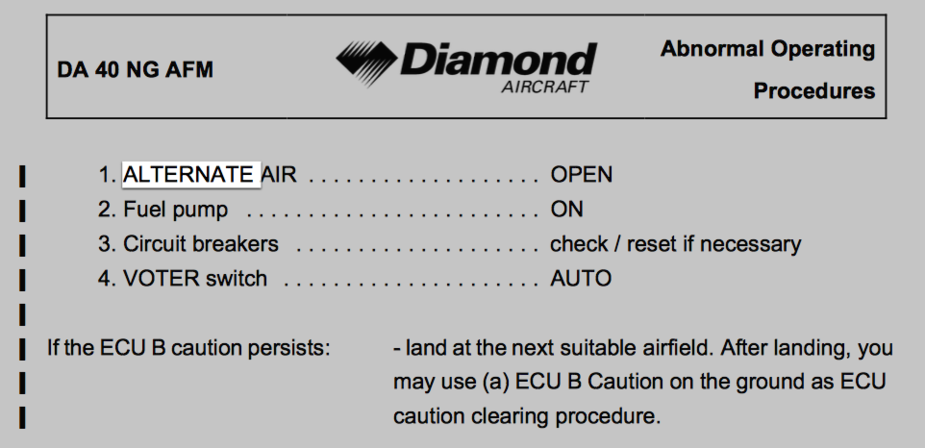

Noe, I would check your checklist version. From the DA40NG AFM regarding ECU failure messages:

Dave_Phillips: Thanks for clarifications on the messages.

I was replying to Peter though, who seemed to imply that you had to fly on alternate air as soon as you are in any visible moisture, which my POH certainly doesn’t require.

Interesting to see that my checklist almost doesn’t mention alternate air, and I don’t have these Vital First Actions you have on your checklist (which all seem very sensible).

Noe, it is dependent upon engine type. As I said earlier, the limitation doesn’t appear apply to older Thielert 1.7/2.0s.

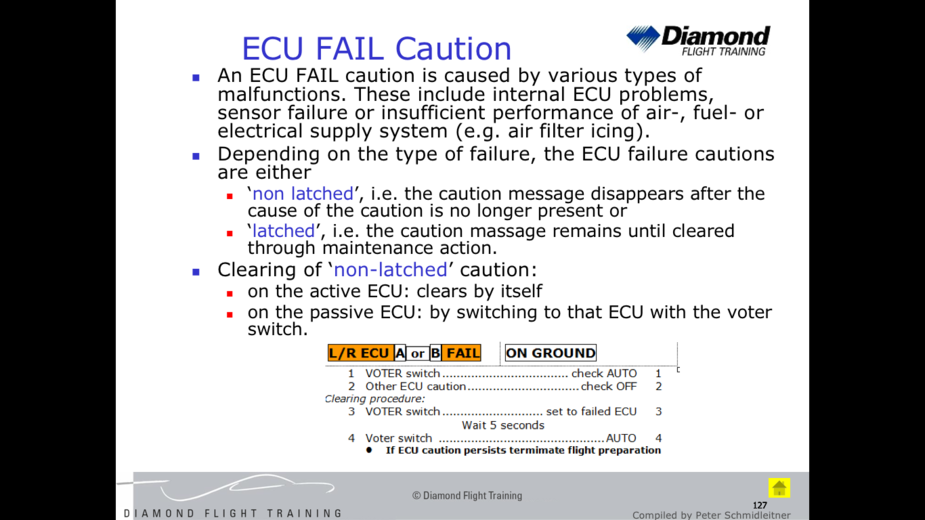

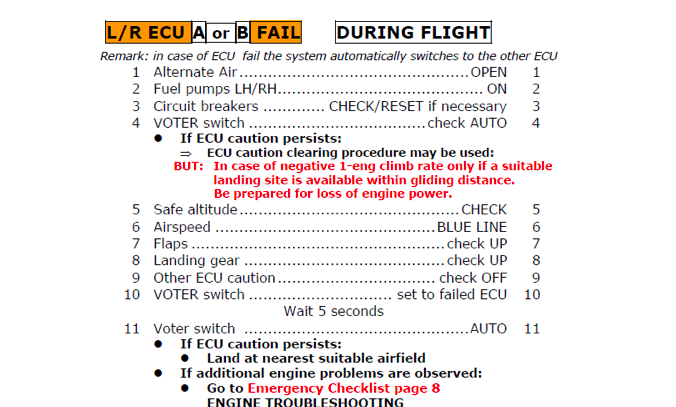

Regarding ECU messages, you either get a latched or un-latched message. A latched message will remain until cleared by maintenance using a laptop and a cable. However, a pilot can clear an unlatched message in flight by following the voter reset routine. As part of the reset routine you get a short message indicating the nature of the failure detected. My experience is that unlatched ECU messages refer to sporadic events that are merely logged. From the Diamond training brief.

ortac wrote:

If it’s a sensor error, report it as such, not as an ECU failure which it isn’t.

Well, it might not be a failure of the ECU itself, but if it’s needed for proper operation, that ECU can’t do it’s job properly. It would be nice to know whether it’s something the ECU/ engine can deal with (with or without some degradation), but the ECU might not be able to tell. Or what exactly is wrong (as the ECU sees it) – you can make an educated guess if you know the engine well enough.

JasonC wrote:

We have to use engine anti-ice from +10c and below in visible moisture. At +9 can ice form on the engine inlet? I truly doubt it but I follow the checklist anyway.

I have heard the +10 as upper limit for icing repeatedly. AFAIK they’re that conservative because the OAT reading could be really off (especially in fast aeroplanes). I do know that at the low end it’s simply a matter of probability (and the “type” of IMC). You can get icing at -30 °C.

“My” POH doesn’t state “any visible moisture”:

True, for any “emergency” situation, but shall we have a poll on how many diesel DA40 or DA42 pilots here really fly with alternate air in any visible moisture?

One thing to consider is a significantly shortened engine life, if the air filter is bypassed. There is a Lyco letter on that topic, somewhere. I have oil analysis data proving a massive increase in the soft metals wear (bearings, basically) if there is even a ~4mm gap in the alternate air door (posted here previously).

I am not suggesting ignoring the POH; I am just saying that this instruction is prob99 bogus, as written.

Peter, won’t you waste more time making judgement calls on what makes or not sense to do, instead of applying the entire checklist in a systematic way? Just applying as is frees the mind, and I imagine makes it much easier for one not to forget / skip (by mistake) and important item.

Sure, Jason, but with your TAS of, what, 450kt max, you are looking at aerodynamic heating of some 20C, and probably almost a corresponding local cooling. Whereas on a DA42 the delta-T is of the order of 2C at most. The relationship of compression heating and TAS is logarithmic.

Peter wrote:

There is surely no case for alternate air in visible moisture. That’s plain daft.There is a case for alternate air in freezing IMC and specifically in specific temperature ranges e.g. -15C becoming -5C due to compression (and whatever else) and icing up the air duct components.

If we assume they didn’t put it in just to give the pilot something to do, then as it is in the checklist prob best to follow it.

We have to use engine anti-ice from +10c and below in visible moisture. At +9 can ice form on the engine inlet? I truly doubt it but I follow the checklist anyway.