Thermawing posts moved to existing Thermawing thread

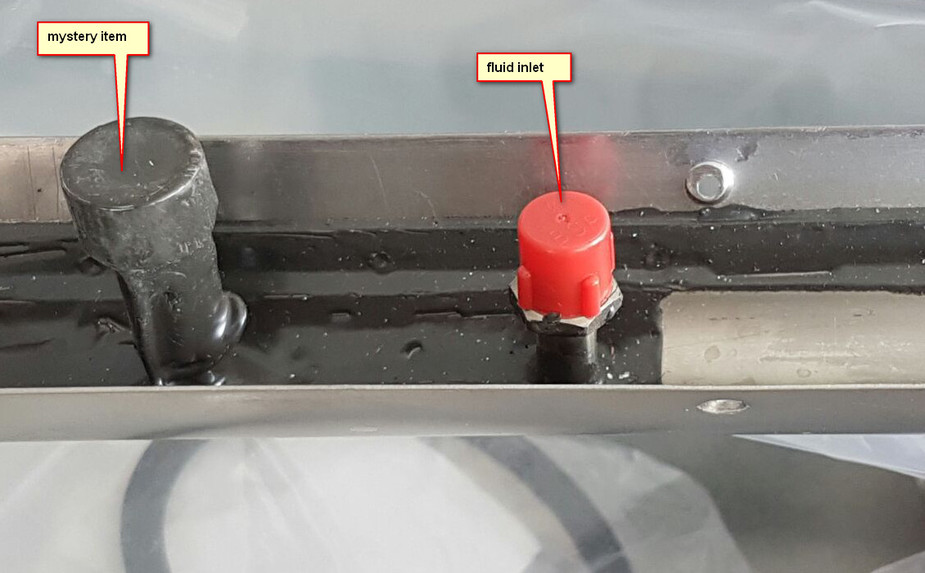

OK, here is another close-up, and a puzzle.

In every TKS panel is this tiny hole; about 0.5-1.0mm diameter

On the inside is this

and there is a tiny metal tube joining the mystery hole to the mystery item:

What does this do?

I think I have worked it out…

The bonus question is: if the tube fitting to the inlet port leaks, will anybody ever find out?? I realise that it should not leak if done up by an EASA145 company  and there should in any case be very little pressure in that fitting because the whole panel is leaking through about 10,000 holes, but….

and there should in any case be very little pressure in that fitting because the whole panel is leaking through about 10,000 holes, but….

No offers on this mystery hole?

pressure compensation?

My friends Bonanza A36TN has TKS since about 5 years and it works as advertised. There was some talk on Beechtalk about corrosion on the wing spar, maybe caused by TKS fluid. It would be advisable to do a Corrosion-X treatment of the whole wing every year if you have TKS installation. It seems to have affected the hinges where the spar meets with the leading edge. A Beech wing has piano wire hinge to attach the front section to the main spar.

I think that thing which sticks up and has been blanked off can only be an overpressure relief valve. There can’t be anything complicated inside there such as e.g. an air pressure sensor to control the flow. It would fail too often and render the whole panel useless; moreover the failure would not be detectable until too late.

Good point dirkj – I have always used ACF50, whole plane every 2 years.

The TKS is non corrosive to Aluminum. We did an experiment before deciding to use it.

However what can be corrosive is the dissimilar metals. I would suggest before installation to make sure the leading edge is epoxy primed and that the rivets are coated. I forget what they used so there was no electrolysis developing.

I seem to remember reading TKS was developed during WW2 as an answer to Flak tearing up the Deice boot rubber.

Interestingly this is a TKS panel from a TB20 installation done perhaps 20 years ago or more. Notice the mesh type of surface… totally different from today’s

It is mostly from these older installations that I got the 5-7kt speed loss reports. I have just found an email from a TB21 non-GT owner whose installation uses the newer panel and was done about 10 years ago and he says there is no evident speed loss, and he confirms the wing drop in stall that I found.

The TKS is non corrosive to Aluminum. We did an experiment before deciding to use it.

However what can be corrosive is the dissimilar metals.

One tip I picked up from another owner is that the belly panels need to be sealed with RTV or similar, to prevent fluid that runs off the wings getting under them and pooling there, and possibly damaging e.g. autopilot servos. We did that on my plane but I wonder how this is solved on other aircraft types? Belly panels are quite thin and don’t lend themselves to having e.g. 3mm neoprene seal stuck to them. With a 1mm thick panel you would need a screw every 2-3cm if you did that. How do Cirrus and Diamond solve this?

BTW that mystery hole is not an overpressure bleed. It is an air bleed hole, and the valve appears to just allow air to vent as the panel is filled.