LeSving wrote:

There are two version of all ULPower engines. A “low compression” and a “high compression”

That’s a good idea, very much like a Lycoming, for example the 150 and 160 HP versions of the O-320.

Non-hydraulic valves strikes me as a bad idea, as with the Lycoming O-235 which also for some inexplicable reason requires valve adjustments. With low speed direct drive engines that’s an unnecessary burden on the owner.

Silvaire wrote:

that’s an unnecessary burden on the owner.

And manual mixture control, carb heat and primer isn’t ?  The point ULPower is making is that no adjustments are needed under normal circumstances, and the engine is operating well. If a large adjustment suddenly is needed, this is a true indication of something very wrong with the valve train. This is masked away using hydraulic valve adjusters. Right or wrong, I really have no idea (time will tell), but checking/adjusting the valves is easily done on these engines.

The point ULPower is making is that no adjustments are needed under normal circumstances, and the engine is operating well. If a large adjustment suddenly is needed, this is a true indication of something very wrong with the valve train. This is masked away using hydraulic valve adjusters. Right or wrong, I really have no idea (time will tell), but checking/adjusting the valves is easily done on these engines.

I own and maintain 12 vehicles which need periodic valve adjustments, including 4 with shimmed desmodromic valve gear. So I’m familiar with the potential benefits of inspection, and the propensity of valves to settle in sometimes after some hours in service. I think on an aircraft engine that runs at low speed, hydraulic valves are wonderful. If you do need to assess valve seat condition, valve recession etc, borescopes do a better job and are becoming widely used. Not a bad idea to have a look every few years and I’ve done cylinder borescope inspections on both my aircraft engines within the last 6 months.

I prefer carburated aircraft engines over injected versions because of their extreme simplicity, one simple carb and often no fuel pump, but in that case simplicity adds little to no operational burden to me – a little more attention to the engine in flight that doesn’t much detract from my flying experience. Most of my flying involves climb/descent to between 5,000 and 10,000 feet and I enjoy managing the engine, just as I enjoy driving manual shift cars over automatics.

Silvaire wrote:

If you do need to assess valve seat condition, valve recession etc, borescopes do a better job and are becoming widely used.

Yes, borescope is needed because of hydraulic lifters. There is no other way to know if something is wrong. Mechanical lifters will tell you if you need to do a borescope. Lots of people prefer things as they always have been. This doesn’t mean old stuff is better than new stuff, it only means lots of people are settled in their ways. Nothing wrong with that, but it’s not worth much as an argument when discussing the merits of new stuff, and new ways of doing things. Very few people have 12 old vehicles that need care also

LeSving wrote:

Lots of people prefer things as they always have been. This doesn’t mean old stuff is better than new stuff, it only means lots of people are settled in their ways.

Sure, reluctance to go forward to hydraulic lifters is probably indicative of VW experience plus lack of specific engineering knowledge. Even though it is 80 year mass produced technology for many companies, several fairly large motorcycle manufacturers have managed to screw up hydraulic valve lifters over the last 20 years, and gone back to solid lifters… so sticking with solid lifters even in this very non-challenging low rpm engine is indicative of risk management.

When checking and adjusting eight desmodromic valves every 10,000 km on a late model vehicle is part of your life, about 12 hours work for me, you appreciate simple aircraft engines and their focus on practicality through design

Silvaire wrote:

Sure, reluctance to go forward to hydraulic lifters is probably indicative of VW experience plus lack of specific engineering knowledge

The point they are making is that no adjustment should be needed – unless something is wrong (which is basically what you are saying about low rev engines). The ULPower “genes” are in professional rally. Building engines and engine parts for the international rally scene (relatively low production runs, specialized parts, high reliability, easy to diagnose, easy to fix and maintain). I would think they know everything there is to know about the good and bad of hydraulic lifters. They got into aero engines by chance. They were asked to fix a Jabiru engine in a helicopter. The helicopter wouldn’t lift off. They removed the engine, put it in a dyno, only to find out it could never deliver the HP needed to get the helicopter off the ground. They decided to use their manufacturing tools and engine know how to make a new engine, rather than to fix the Jabiru. That’s how the (pre) 260i was born. An engine built from scratch fitting the Jabiru engine mount. I think I remember it only had 2500 cc and relatively high rev, 3500-4000?

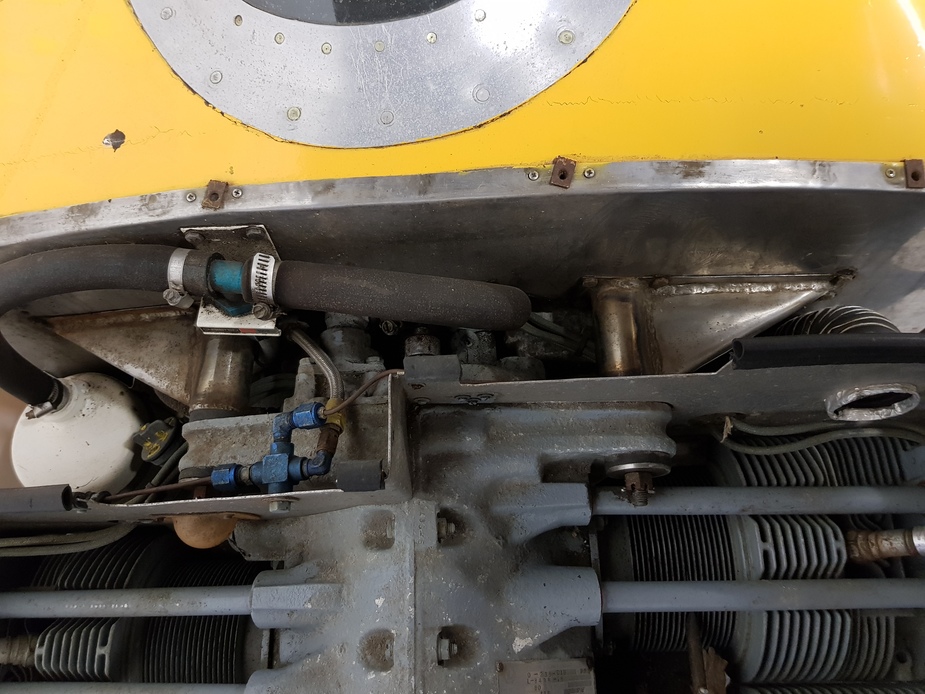

The production version 260i came in 2006, but then as a pure aircraft engine, a drop in replacement for the Jabiru 2200. Then came the 260iS and 260iSA when the Twister Team wanted an aerobatic version of the engine for the Silence Twister:

Then it just took off with 350i, 350iS, 350iSA and finally the production helicopter engine, the 350iHPS in 2010 with 145 HP.

In 2013 the 6 cylinder version started appearing: 390 and 520 i and iS versions with 140 to 200 HP.

The engine(s) is what it is. Boxer engines with high power to weight ratio, air cooled, very high quality and precision in every detail, FADEC. The only down side (IMO) is the cost. They are far from cheap, but I hope they will make it up by low maintenance cost and free of trouble

FWIW I’d take a lifter-inspection over the Magneto timing/inspection anytime.

Okay, I don’t have access to them in an easy way…

But now as you mention it… for the weight of the O235, I can add considerable power to the airframe by chosing an UL390 or UL520… hmm..

Why has the UL-Power powered Twister a “Diesel only” sticker around the filler? Do you know that, @LeSving?

LeSving wrote:

They were asked to fix a Jabiru engine in a helicopter. The helicopter wouldn’t lift off. They removed the engine, put it in a dyno, only to find out it could never deliver the HP needed to get the helicopter off the ground. They decided to use their manufacturing tools and engine know how to make a new engine, rather than to fix the Jabiru.

That’s interesting because the story of how Jabiru came from the KFM engine is similar. In that case the original engine was a nice looking thing developed by an Italian go-kart engine company, but it had problems and they dropped it. Jabiru was a customer left in the cold and used the engine as the basis for their own engine.

The Thielert engine apparently came from a discussion made at Frank Thielert’s Christmas party one year. The story goes that he and the eventual lead designer (who worked for him) took a bet from Christian Dries. Thielert was also a racing car engine company as I understand it.

mh wrote:

Why has the UL-Power powered Twister a “Diesel only” sticker around the filler?

I haven’t noticed. Looks odd  It could be smoke oil ? The ULPower is certainly not a diesel engine, and no diesel engine could ever fit into the Twister.

It could be smoke oil ? The ULPower is certainly not a diesel engine, and no diesel engine could ever fit into the Twister.

Silvaire wrote:

When checking and adjusting eight desmodromic valves every 10,000 km on a late model vehicle is part of your life, about 12 hours work for me, you appreciate simple aircraft engines and their focus on practicality through design

What late model vehicle has desmodromic valve gear?