Seriously doubt that ANY significant wing design change could be financially viable.

I’m sure that’s correct. If you’re really stuck on a tapered wing to go with your 90 gallon tanks, big cabin, stabilator and IO-540, its not so hard to find a Comanche 260.

Contrary to what @achimha says, the article writes “…above all (the Continental CD 230 engine) maintains 100% power up to FL125 whereas the Lycoming only produces 60%.”

The critical altitude of the original SMA is way below FL125 and the nature of the turbo diesel means that power will bleed off much quicker above critical altitude. The CD230 TB20 will not even get near the ceiling of the Lyco TB20.

I do not believe in diesel retrofits that perform significantly worse than their avgas original. Of the SMA STC’ed 182 very few were made (with a terrible cooling design!) and the Cessna factory version of it with the new SMA engine is still not certified. I hope it will because it looks like a good aircraft with the much improved 2nd generation SMA. Very pricy though and significantly worse performance than the T182T it is supposed to replace.

I don’t see much point in trying to restart the TB20. It has no real advantages over the Cirrus which will also get a diesel engine (or two? three?).

@achimba – The critical altitude of the original SMA is way below FL125 and the nature of the turbo diesel means that power will bleed off much quicker above critical altitude. The CD230 TB20 will not even get near the ceiling of the Lyco TB20.

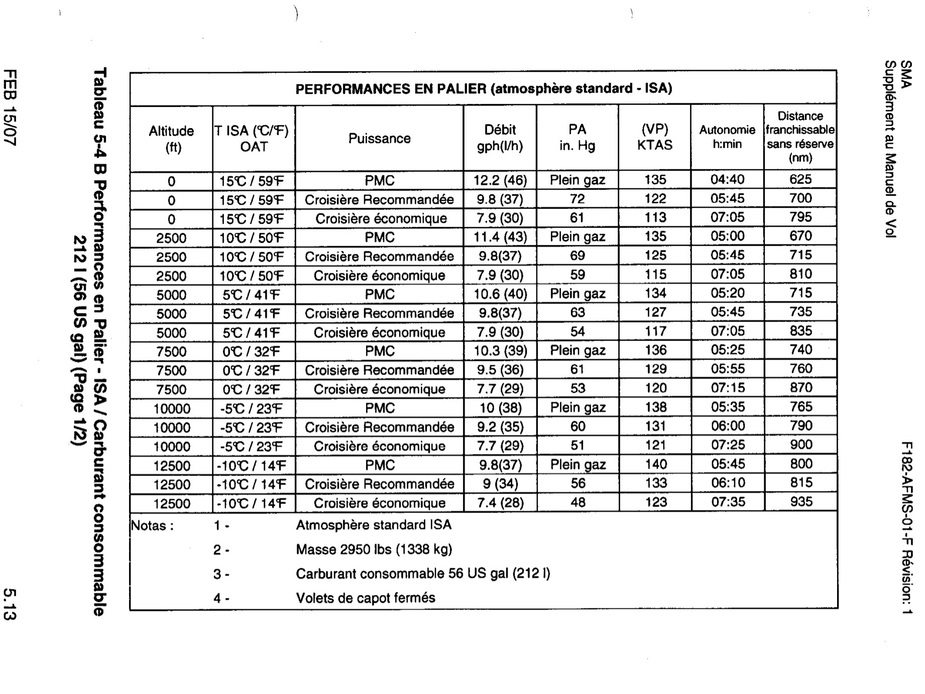

I found here the AFM for Cessna 182 P & Q equipped with SMA SR305-230 engine. Document is in French, but I have extracted this table which shows decent performance up to FL125.

I found here the AFM for Cessna 182 P & Q equipped with SMA SR305-230 engine. Document is in French, but I have extracted this table which shows decent performance up to FL125.

Yes but the SMA C182 is a replacement for the T182T which has very decent performance up to FL200. There is no comparison — which is sad. The Thielert C172 was also performing poorly compared to the standard O-320 C172 until the 155hp Centurion 2.0s. They’re making the same mistake again, a TB20 for a lot more money with a lot less performance. Same the Deltahawk with the Cirrus SR20 which is massively underpowered in its original version already.

The most promising Diesel project in my view is the Thielert V6 Cirrus they’re working on. The C172/PA28 with the 155hp Thielert are also good flight school machines, especially when Jet A-1 is significantly cheaper or better available.

I do not believe in diesel retrofits that perform significantly worse than their avgas original.

I don’t think such a concept will sell because almost nobody wants to downgrade. And 230HP is a big downgrade in takeoff and initial climb performance from 250HP.

Why SMA didn’t go for 250HP – such an obvious thing – I don’t know but I guess they must have had a good try and gave up. That in turn suggests the engine is somehow marginal at 230HP.

I don’t see much point in trying to restart the TB20. It has no real advantages over the Cirrus which will also get a diesel engine (or two? three?).

Not at the same price as the SR22, of course. But the SR22 is already eye wateringly expensive and getting more expensive with every new iteration. There is IMHO almost no market for SEPs as they head for the million dollar area, no matter how many avionics gizmos they come loaded with.

The SR22 is also not particularly fuel efficient; they did well with a slippery fuselage and then threw away much of the advantage with the fixed gear.

I am sure there is considerable scope for cost reduction in these things. Cirrus could not attempt that because they cannot undermine their existing business, and anyway there are limits to what can be done while building in the USA. But a new player does not have an existing business and building in N Africa would reduce costs substantially. The TB20’s aluminium construction, for example, lends itself to significant cost reductions. What I don’t know is the Garmin OEM pricing for the G1000 (or some successor) and their autopilot, which seem unavoidable for a new IFR certified aircraft.

In 2002 I paid $300k for the TB20GT. There has not been any significant cost inflation in the intervening 12 years in the areas which make up that aircraft. Another thing is that the dealer got 15% of that, for doing essentially nothing. In Europe, which is a very small place, dealers add almost no value. Probably the biggest thing they do is rip off customers who are too lazy to even remember when their Annual is due, and drop the plane off with a pre-signed blank cheque on the seat.

Seriously doubt that ANY significant wing design change could be financially viable. The discussion here is just journalistic rhetoric

Look at the RV-10

Better performance overall than the 310 HP Cirrus, and it does this with 260 HP and a square constant cord wing.

What is the cockpit volume of the RV10, compared with the TB20 or the SR22?

If I wanted to make a TB20 go faster, I would

That should give you 10kt.

The ADF antenna alone must be worth 1-2kt. The VHF ones are 0.5kt each.

A cowling with smaller holes (and the then necessary cowl flaps) would give you another few kt.

It would be dead easy to do a composite VS, even on a DIY (obviously illegal) basis. It has no moving parts. The rudder would stay the same.

If I wanted to make a TB20 go faster, I would replace all the rivets with flush ones – a straightforward procedure, if quite time-consuming

move all antennae out of the slipstream – might need a composite vertical stabiliser, or at least a leading edge

That should give you 10kt.

The ADF antenna alone must be worth 1-2kt. The VHF ones are 0.5kt each.

A cowling with smaller holes (and the then necessary cowl flaps) would give you another few kt.

It would be dead easy to do a composite VS, even on a DIY (obviously illegal) basis. It has no moving parts. The rudder would stay the same.

Sure one might eke out a knot or two with those mods, strange that Socata didn’t do them for the GT models.

But, I’m guessing that the [fat] wing is already at it design limit in terms of cruise speed and that will keep you from getting anything more out of it.

Since the wing in a typical GA aircraft produces some 80 % of the total drag, even slight gains have a direct impact on cruise speeds.

Making rivets in thin sheet flush is a lot of work – can’t just countersink, as you know  You have to countersink the spar (or whatever is underneath) and dimple the skin.

You have to countersink the spar (or whatever is underneath) and dimple the skin.

The TB series has what I call a fat wing airfoil as compared to a thin or Laminar Flow airfoil, hence it is not very sensitive to surface imperfections. I doubt that any significant gains would be achieved by going to flush rivets.