@achimba – Yes but the SMA C182 is a replacement for the T182T which has very decent performance up to FL200. There is no comparison — which is sad.

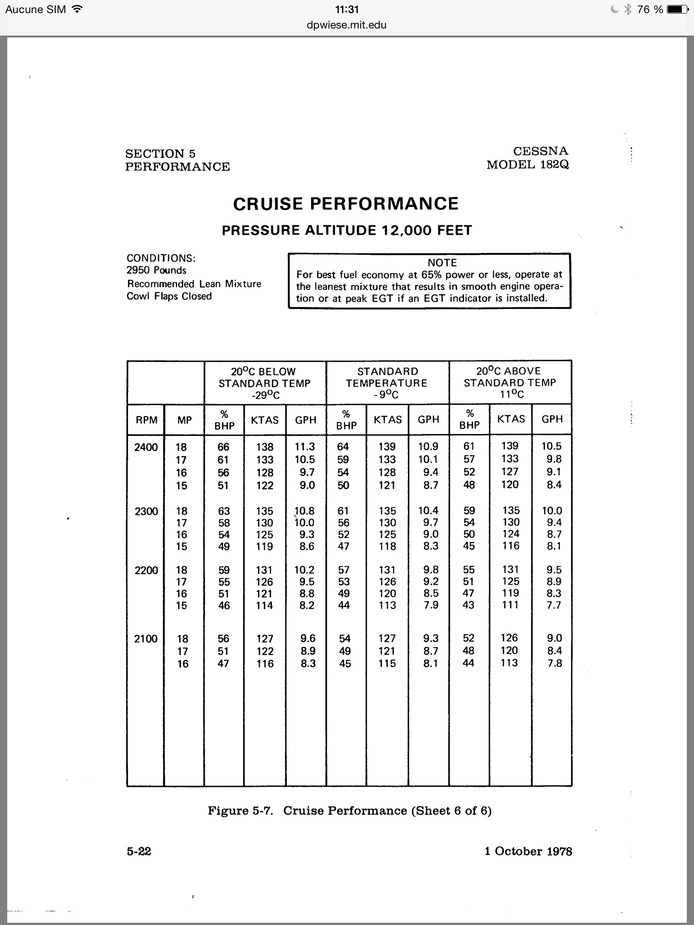

This isn’t correct. The SMA SR305-230 STC is for the normally aspirated Cessna Skylane 182 Q & R. In the conventional Cessna 182 Q AFM (here), one can see that the powerplant only provides 66% power at FL120, which translates into 139kt and 10.9 GPH. See following image:

As you can see in the AFM for converted Cessna 182 Q equipped with SMA SR305-230 engine in my previous post above, performances are quite close. At FL125, the SMA diesel version provides 140kt @ 9.8 GPH at full throttle (for which it is approved) and 133kt @ 9 GPH at recommended cruise setting.

After receiving the design and license from SMA, Continental started improving the original SR305-230-1 design for its CD230 engine, in a similar philosophy as that of SMA for its evolved SR305-230E for the new and not yet certified Cessna 182 Turbo Skylane JT-A, with an operational ceiling of 20,000ft.

This should support some belief that the TB-20 upgrade could lead to similar performances.

Back to the Aviation & Pilote article, the magazine writes: “The Continental CD 230 seemed the best choice to replace (the original Lycoming AVGAS engine): it’s based on Diesel cycle, it’s easier to manage with its single-lever control, it burns 35% less fuel, requiring down to half less JET-A, and, more important, it maintains 100% power up to FL125 whereas the Lycoming delivers only 60%. One must certainly admit it provides 20 bhp less nominal power, but as the Lycoming engine performances are affected by altitude and ambient temperature at ground level, we can consider that the effective nominal power difference (4%) in not significative. (…) So, at FL120, at same weight, the present TB-20 which flies at 154 KTAS (Wmax 60%) burning 53 l/h of Avgas, would deliver 170 KTAS (Wmax 90%) with 37 l/h fuel flow with the CD 230 engine. As evidenced by an initial market study, this (phase 1) STC is much awaited by present owners seeking to re-power their TB-20. Approx. 50 of them are already on a waiting list.”

Let’s not start a nationalist discussion on this

The most operationally advanced aero-diesel engine programs are (by order of success and advancement) those of (i) the late Thielert/Centurion, now Continental and of those of (ii) SMA, which started as a Renault-Socata JV and is now an integral part of SNECMA, part of SAFRAN Group. Both Continental and SNECMA are recognized and experienced aircraft engine manufacturers, which, I think, is important and is the reason why I didn’t mention Austro-Engines. What they achieve is great, but very similar to Continental’s Centurion product range. With the combination of SMA and Continental, one can have serious hopes for soon having a complete range of diesel piston engines for general aviation, from 135 bhp up to 400/450 bhp, with decent global after-sales support (Continental with its own service centers network and SMA through their agreement with Textron-Lycoming).

With this dual and competitive approach, industry is investigating very efficiently in parallel alternative technologies or solutions wich, at this stage, look equally promising:

The SMA SR305-230 STC is for the normally aspirated Cessna Skylane 182 Q & R.

Only a handful were made and I think none in the last few years and none with the 2nd generation of the SR305? The real deal will be Cessna’s SMA C182 and that was positioned as the successor for the turbocharged Lycoming T182T which it can hardly complete with in performance.

it burns 35% less fuel

The numbers you give are “139kt and 10.9 GPH” for the NA C182 and “140kt @ 9.8 GPH” for the SMA STC which is 10% less of a fuel that weighs 10% more.

as the Lycoming engine performances are affected by altitude and ambient temperature at ground level

So is the diesel engine.

I don’t think the TB20 is a good target for the SMA engine. Aircraft has been out of production for 12 years, not that many were made (compare it to the C182) and apart from performance, it will suffer greatly from the increased weight and thus reduction of useful load and possible restriction of the loading envelope.

The oil price decline doesn’t help aero diesels either.

@achimba – Only a handful were made and I think none in the last few years and none with the 2nd generation of the SR305?

This is correct. In 2011 SMA stopped production of the retrofit kits for C182 P & Q. Here is the answer I received in October 2013 from the Dutch company Masterbroek Aeroskill after sending them a request for a C182 SMA retrofit installation:

“Thank you for your inquiry about the Cessna diesel. Unfortunately SMA stopped production of the conversion kits in 2011. They, nowadays, only supply kits and engines to Cessna for the new Cessna 182 JT-A. Only 45 aircrafts have been modified and we sold the last 2 available, earlier this year. Presently there are no Cessna diesels for sale, as far as we can see. If we have one coming in, we could keep you posted, if you’re interested.”

They seem to have recently sold another one (used) and give some advantageous comments on its performances there).

I’m under the impression SMA stopped their STC plans not for technical or operational but for “commercial reasons” after entering into negotiations with Textron (Cessna & Lycoming). I imagine Textron realized Safran and SMA were very eager to get this deal and requested a sort of exclusivity. When one sees the Turbo Skylane JT-A proposed selling price (even before certification: US$530k here), it’s easy to understand that having the same aircraft (used) retrofited under an STC for the very same engine at, say, US$250k, would ruin their business plan.

This could also explain why SMA never communicated on the very open license they appear to have sold to Continental engines for the older version, with all rights to modify it…

@achimba – The numbers you give are “139kt and 10.9 GPH” for the NA C182 and “140kt @ 9.8 GPH” for the SMA STC which is 10% less of a fuel that weighs 10% more.

I’m not experienced enough at making these comparisons. Maybe you could help me analyzing both AFMs? I hear diesel + turbo is still a good advantage in most of the cases (operationally speaking), maybe for hotter days or different power settings? At least that’s what the press says. Plus the advantage of moving away from leaded fuel (Avgas), for expensive high performance airplanes you might want to use to travel the world.

The C182 STC from SMA was lacking in many ways. It was done in a rather quick and dirty way it seems, without much insight into the actual airframe. The whole cooling airflow design is pretty horrible. I can understand that SMA came to the conclusion that they can’t both produce great engines (which they do) and great airframe installations. Comparing the JT-A to the SMA STC shows huge improvements in the installation. Besides the hefty price tag and the poor performance compared to the T182T, the JT-A looks like a really good airplane to me.

STC for the very same engine at, say, US$250k, would ruin their business plan.

You can buy the SMA SR305-230E for ca. 90k€ plus VAT. Nothing should stop companies from coming up with a good STC… only the small market. It’s so much cheaper to overhaul/renew an avgas engine and avgas is still easily available where you find GA aircraft and the price is still low enough to keep people from installing diesels.

the very open license they appear to have sold to Continental engines for the older version, with all rights to modify it…

I wonder how Continental did something useful with that design. For this you need real specialists with experience and I wonder where they got them from. I haven’t seen any aircraft with the CD230 so I remain sceptical.

Nestor – Big difference between the Legacy 182 Q & P models and the re-start, Lycoming versions.

For the kind of budget we’re talking about for the SMA STC, you could easily buy a restart G1000 / Lycoming model with it’s greatly enhanced performance over the legacy models.

Here is more on the Continental evolution of the SR305-230-1, 230 bhp diesel aircraft engine. Informative interview by Paul Bertarelli of AVweb TV in July 2013:

Video includes :

)

).36 SFC (dunno what this means. If SFC=Fuel Flow

That should read BSFC : Brake Specific Fuel Consumption

Thanks @Michael. However I still can’t get anything workable from this .36 BSFC.

Here on Wikipedia, BSFC = r : P,

so r = BSFC * P

where

r is the fuel consumption rate in grams per second (g/s)

P is the power produced in watts

In our case P would be 230 * 1,36 * 1000 = 169,117 Watts

so the fuel flow, r should be 169,117 * 0.36 = 60,882 g/s

equal to approx. 60,882 × 3.6 : .804 : 3.79 = 72,000 GPH…

I must have missed something.

The figures used by in the US in your example are lb/(hp.h)

BSFC [lb/(hp·h)] = BSFC [g/(kW·h)]×0.001644