@lelievre12, a friend of mine has a P210, it’s a fantastic airplane. Quite frankly – if you have a P210 then the only way up, IMHO, is a PA46 (if you’re on the short side), a TBM, a PC12 or a twin.

Hi @leliever12 ! I watched with interest some of your Youtube videos a long time ago when looking for ref data on the P210 before I acquired one, interesting one with the STOL competition!

lelievre12 wrote:

My climb rate in the P210N is around 350FPM to 20,000 at ~30GPH. The EA climbs twice as fast at around 35GPH. I burn 30 gallons to 20K whereas the EA400 only needs around 18 gallons to the same altitude. That’s 12 gallons (72#) less for the EA400.

Something is wrong about your P210. Our P210 routinely averages 500fpm all the way to 20000ft and uses 14USG in the process, and we don’t live in Sweden but Spain (ie ISA+10C or +15C) . You can look at FA or FR24 data to verify. PM me if rq’d. Our engine is the standard TSIO520P with Riley intercooler ( I believe same setting as yours) and our power setting for climb is 2500/31" . At ISA+15 we sometimes need to increase RPM to 2550 above 18000ft to maintain 31" MP in the climb. Levelling off we get MP back with the ram effect.

Maybe this belongs in some of the other threads on the P210 where I am probably long due for a proper writeup of my six-year experience.

Galatea is flying again.

It has been turbulent times and things did not go as expected, to say the least. But with a little help from my friends, we got her back in the air, finally.

See this video of my first test flight with “new” engine, prop etc…

We had a meetup of 3 E400 pilots and after the first flight showed no dangerous issues, we dared make a 30 minute flight together.

All three of us were under the impression that the new engine felt more powerful. I tried to document that:

If fuel flows for a given TIT, MP and RPM combination is an indication, then we are looking at 12% more power than before…

This is consistent with the 307 HP that were measured without turbo by LOMA AIR during their break in.

My friends also liked the results of the cleanup effort on engine hoses, ducts, cabling and especially the final layout of the pressurization ducting.

With the engine removed and the silly time it took to get it completely reinstalled, there was time to challenge the position and routing of every sensor, duct, hose and cable.

The highest priority was to increase safety of the pressurization system. This was achieved by repositioning two mixers on the firewall and dramatically reducing the length of the SCEET ducts.

The next was to improve accessibility, free-up airflow inside the cowl and prevent chafing.

Finally, we dealt with the nasty hot spot near the turbocharger which is powerful enough to delaminate the carbon fiber of the cowl, despite an abundant layering of fiberglass mats. That was an expensive repair which fully justified the following:

The fix consists in a sheet of 0.5 mm dimpled Inconel riveted to carbon fiber spacers in the inner side of the cowl at approximately 1.5 cm (about .5 inch) distance from the surface. This allows air to flow between the cowl and the heat shield and YESS it works: this area is now actually cool after landing.

Overall we saved several Kg in the nose of Galatea.

I’d love to say the nose does feel lighter now, and it is easier to keep the nose up after touchdown but that’s probably an illusion.

Still tbd before we can resume travelling: the fuel system needs a proper post-overhaul adjustment and we need to recalibrate the fuel gauges of the EDM930 .

Once the fuel system is well tuned, I am eager to try a climb to 25’000 fet and perform a 75% speed test there.

I read and hear the warnings from past E400 owners here. And I stick to my statement: do not buy an E400 unless you are very technical, can be the maintenance manager and do not mind cancelling a trip due to AOG. An E400 is not a cheap TBM!

If you fit the profile and are willing to spend the amount of your purchase price again in various upgrades, fixes and repairs after purchase, then you will be a very happy camper… Nothing beats the remarkably sporty handling and the “jet like” atmosphere in the cockpit.

If you are willing to pay for a full cabin makeover, your passengers too will experience jet-like comfort and luxury, because the layout is excellent, well worth every penny spent on nice leather, beautiful stitching etc…

Add pressurization that really works, FIKI, performance and fuel efficiency and you get the idea. A wonderful toy…

QuoteHowever (amazingly) stall speeds are exactly the same

That’s because they start from the stall speed and solve for the MTOW which gives it, isn’t it ?

Flyingfish wrote:

Galatea is flying again.

Well done

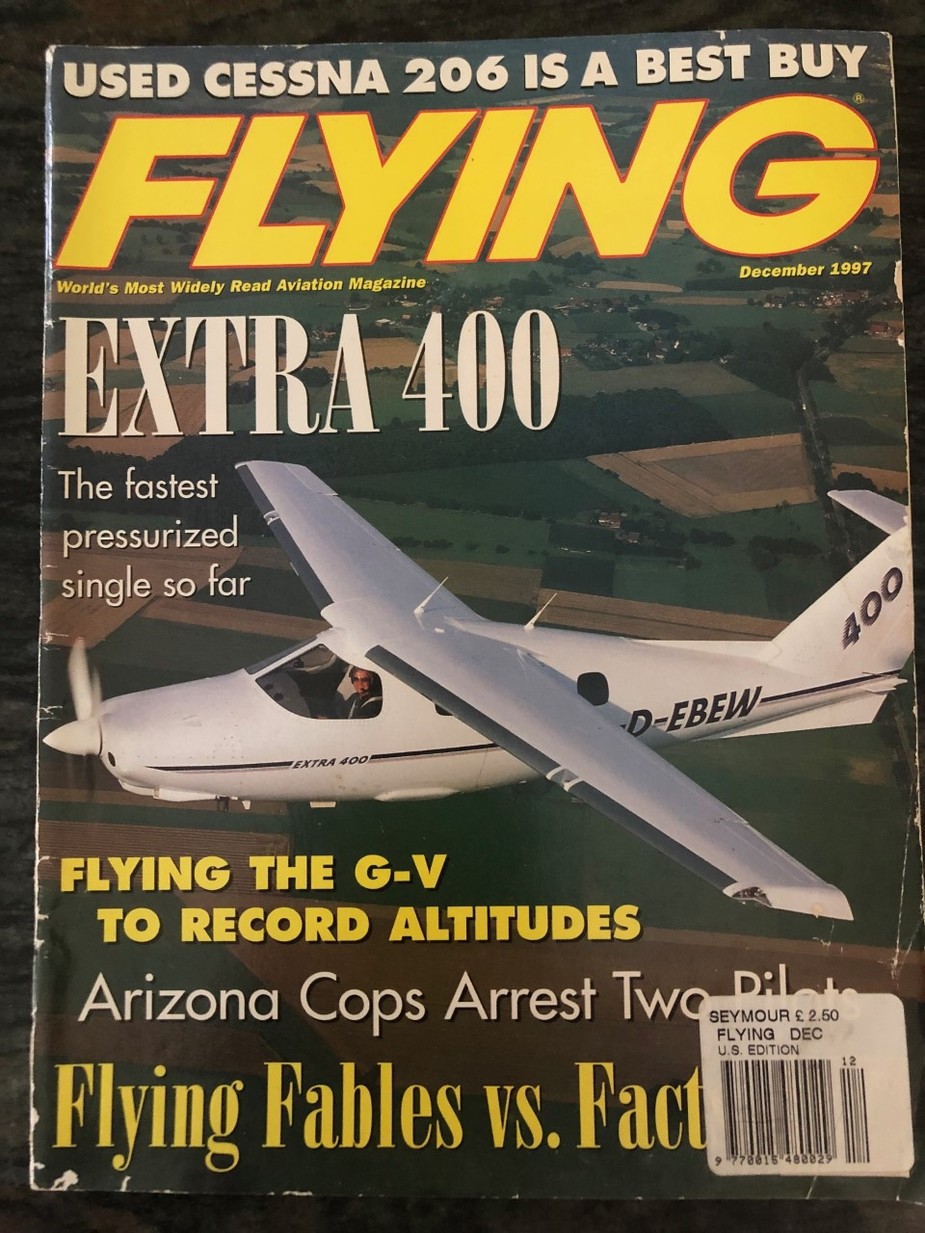

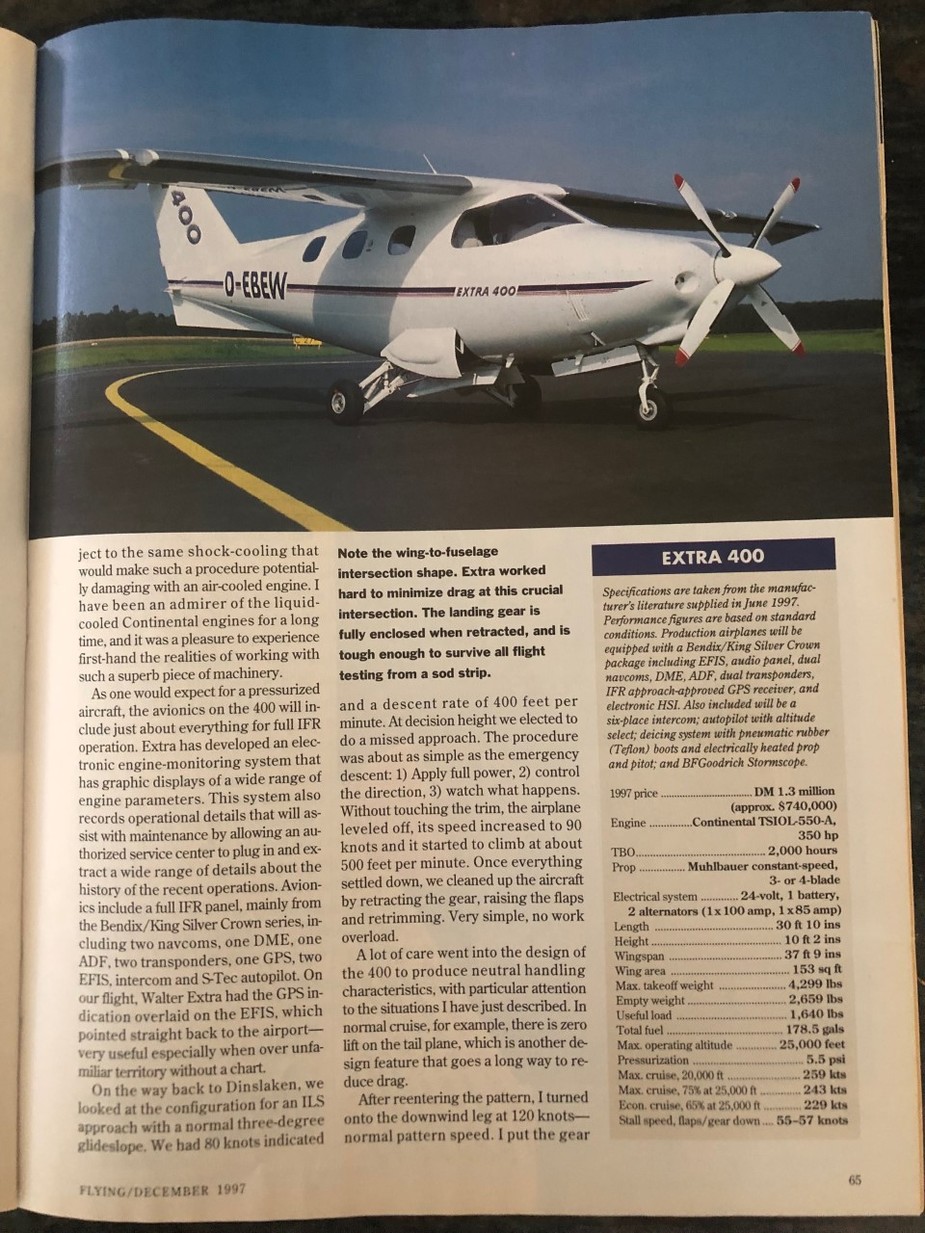

I thought that you would like this, if you dont have the original mag I will post it to you

@quatrelle this is a very very nice idea. I would love to have this and will keep it on behalf of our small and informal E400 owner group. I’ll you mail some very special swiss chocolates in return!

Flyingfish wrote:

this is a very very nice idea. I would love to have this

Please let me have your address and I will post it to you, or Peter will give you my phone no and you can call me

Thanks a lot for those pics. It always makes fun reading to get something else in the info stack. I’ll save those as well.

Fun also to see FlyElite. I remember them well (they still exist I think), their company for a while was very close to where I live and I sold some of their systems while working in flight simulation. I even still have one of their original power sets somewhere and the DOS Software. It was a revolution at the time and prompted BAO to make a panel similar to Elite for Microsoft FS 4. Ah the memories.

Update: after sitting for 18 months, Galatea had some minor issues which are being ironed out:

We serviced the shimmy damper and replaced the almost new nose tyre.

Some advice if you are servicing a shimmy damper: you need to extract all of the air that is trapped inside. And here’s the catch and solution:

Typically, the piston assembly is made of a steel rod and a cylindrical piston with calibrated holes. That assembly requires a cotter pin. Air will get trapped in the mounting hole. After failing once, I placed the whole piston assembly in a bag full of hydraulic fluid, tape-sealed it to a vacuum pump and pumped until only getting fluid out.

After that I inserted in the cylinder, poured the liquid in and had the end cap press the excess out with minimal force application. Another heads-up: while reinstalling in the plane keep in mind that the shimmy damper must be able to pivot. Overtorquing is not a good idea…

It was messy and scary project, but works very well now.

And so does the plane except we cannot presently climb to high altitude due to a squat switch defect which disables pressurization.

There’s good news though. We altered fuel flow, adding a generous 2.5 USG /10 liters per hour to the full power setting. The result was spectacular:

We departed using full power in ISA+20 with a heat soaked engine and climbed at max climb power to FL100. In flight air T was ISA+15.

Not only did Galatea NOT overheat, but coolant and oil temperatures were actually trending down under full climb power settings (37.5 inches and 2500 RPM).

The aircraft is going back in the shop early September for a 25 hour oil change and a few minor issues.

All in all very happy and looking forward to some serious flying this fall and winter

I have a question to our alternator gurus: There’s a PMA alternator from Plane Power with a 150 Amp rating that would make a good replacement for the belt driven 80 Amp unit. I do not intend to use any more than 80 amps. Am I correct to assume that the voltage regulator can deal with this and that the whole setup can be derated to only deliver 80 amps? My expectation is that the PP unit will deliver a lot more amps near idle, at a lower weight right where it is most beneficial…

The high output alternator will not deliver any more current than required to maintain the output bus at specified voltage. It’s not derated to do this, it’s the normal function of the device. I’m not sure if this is a permanent magnet or conventional excited field machine, this affects the regulator technology but regardless if you want to maximize idle speed output you’ll need full field excitation to be available. Approval of the installation will therefore very likely require that the bus be able to safely absorb the full rated power of the device.

A machine rated for high output power at high speed will very likely make more power/current at idle too, but it’s not guaranteed. It depends on the detail design of the alternator and it might be worth asking about the max output versus speed if you have e.g. substantial loads to start on the ramp before takeoff and limited battery capacity.