Just about to sign on a hangar at my home airport after being on a waiting list forever. But it’s an insane tight squeeze. It’s a T-hangar, and the critical measurement is from flap trailing edges to the nose. I have inches to play with. So the only way to be able to make it work was by ordering one of those remote controlled tugs from AC Air Technology. I’d known about them and been impressed with them for awhile, but saw no need for it as I was parked outside. But to be able to fit the plane in this hangar, it became a necessity. Now I can control the tug and be right up next to the critical parts as I drive it in or out.

They’re built by Anthony Chan and he also owns a Commander funnily enough (he has 681). He has a 2 month backlog on these things so they seem to be selling like crazy. I like that I can take it with me, too – just chuck it in the baggage compartment. He says he uses same Panasonic battery packs as Tesla uses, so they should be safe to travel with. I ordered the T1.5 model which he said is plenty for the Commanders. He even towed a Learjet 60XR with it.

Got the hangar! But still have no plane!

AdamFrisch wrote:

He even towed a Learjet 60XR with it.

One has to be careful with these tug claims. IN the right situation I’ll bet ya I could move a Learjet 60 all by myself

The REAL ACID TEST is at YOUR hangar with any gradient and maybe less than perfect surface – read gravel, rough spots, cracks, etc.

It’s pretty flat, but my main worry is if it will be able to go over the tracks to the hangar doors. If it doesn’t, I’ll have to get a golf cart to tug it in over the tracks and then let the little tug take over. More complicated, more time consuming and opens up to errors. I’ll have to wait to find out.

You can probably make fillers to smooth out the gradient of the tracks if necessary. Rubber matt and/or wood depending on the height and spacing of the tracks.

I can’t believe the tail fits in the hangar!

I got one too last autumn. It was a T1X.

First it wouldn’t go over hangar door track. We bought some rubber mats.

Next, it was not table to climb a small gradient outside of the hangar. It would overheat after pulling the TBM for 5-10 meters.

After a few weeks a track snapped. We didn’t bother fixing it.

It’s a nice device, but requires a perfect environment.

Bigger, more robust and able to cross tracks:

http://towbots.us/

Yeah, I found that an $0 Soviet era helicopter tug does the job equally well.

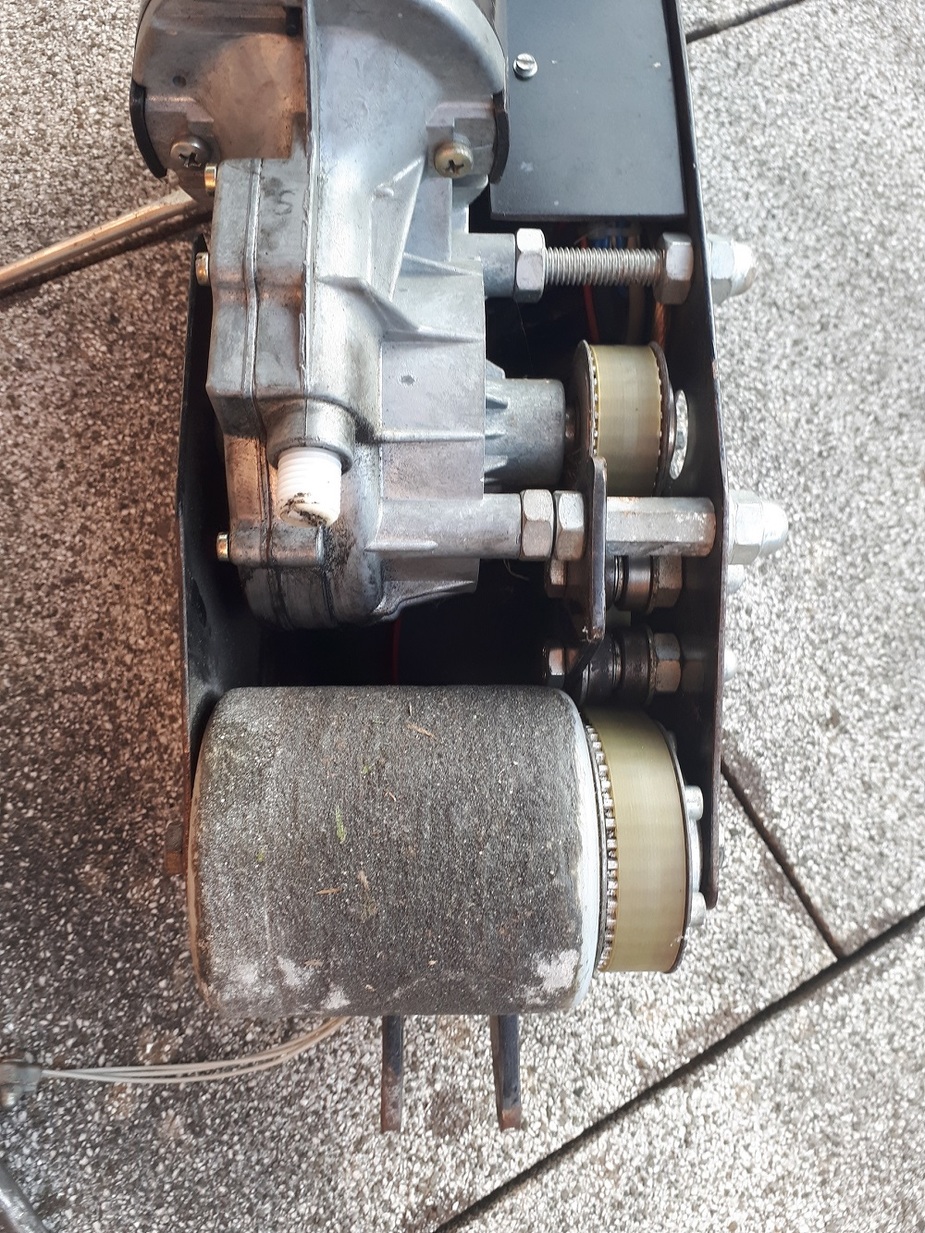

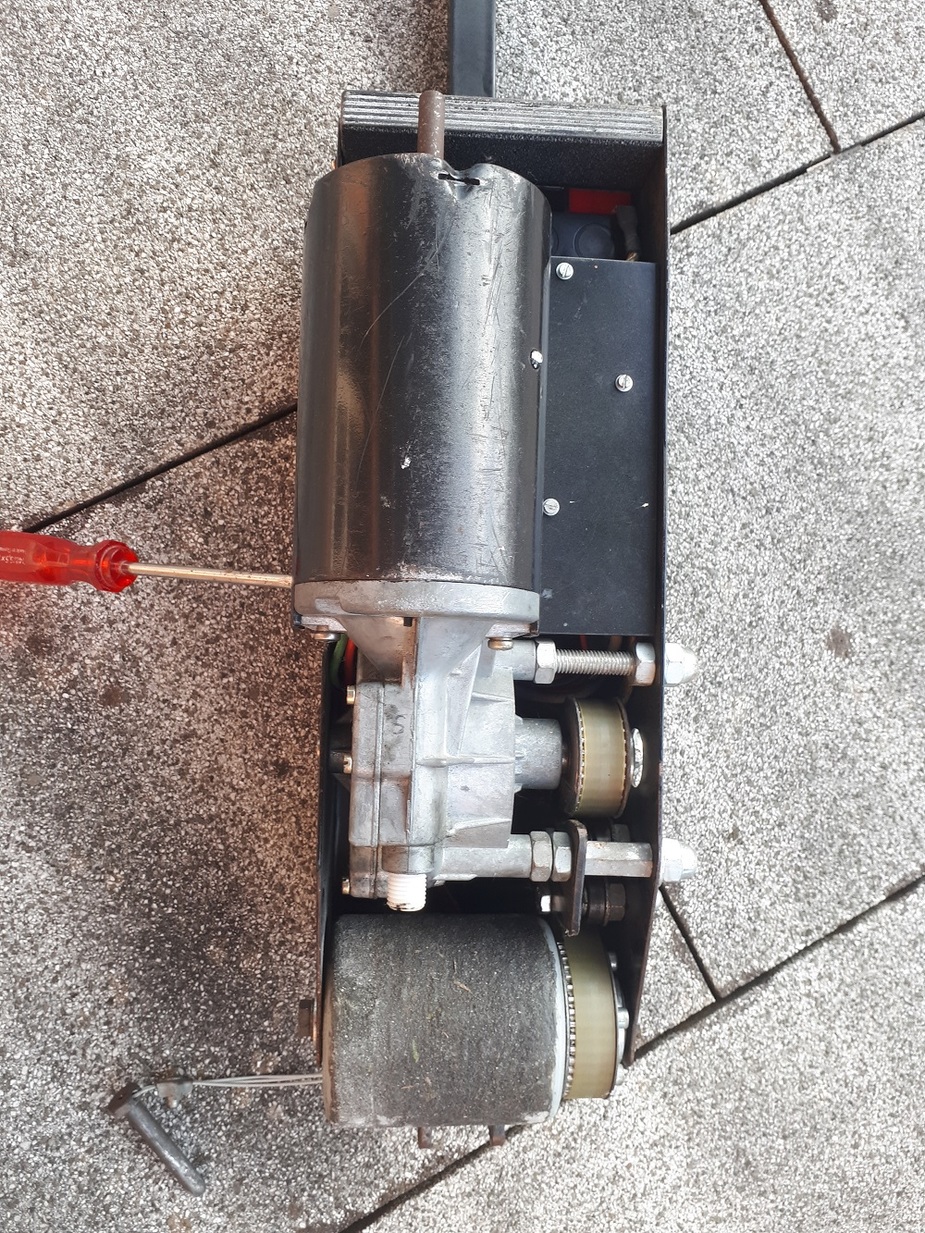

Inherited from previous owner, an electric towbar with standard industrial battery units (just replaced – several years in the hangar w/o charging or usage).

After charging it twice, it still seems rather weak – so there could be an issue with the drive or the motor itself.

Looked like a totally enclosed model. Not much to check, other then a serious dismantling & rebuild (an idea I am not to fond of)

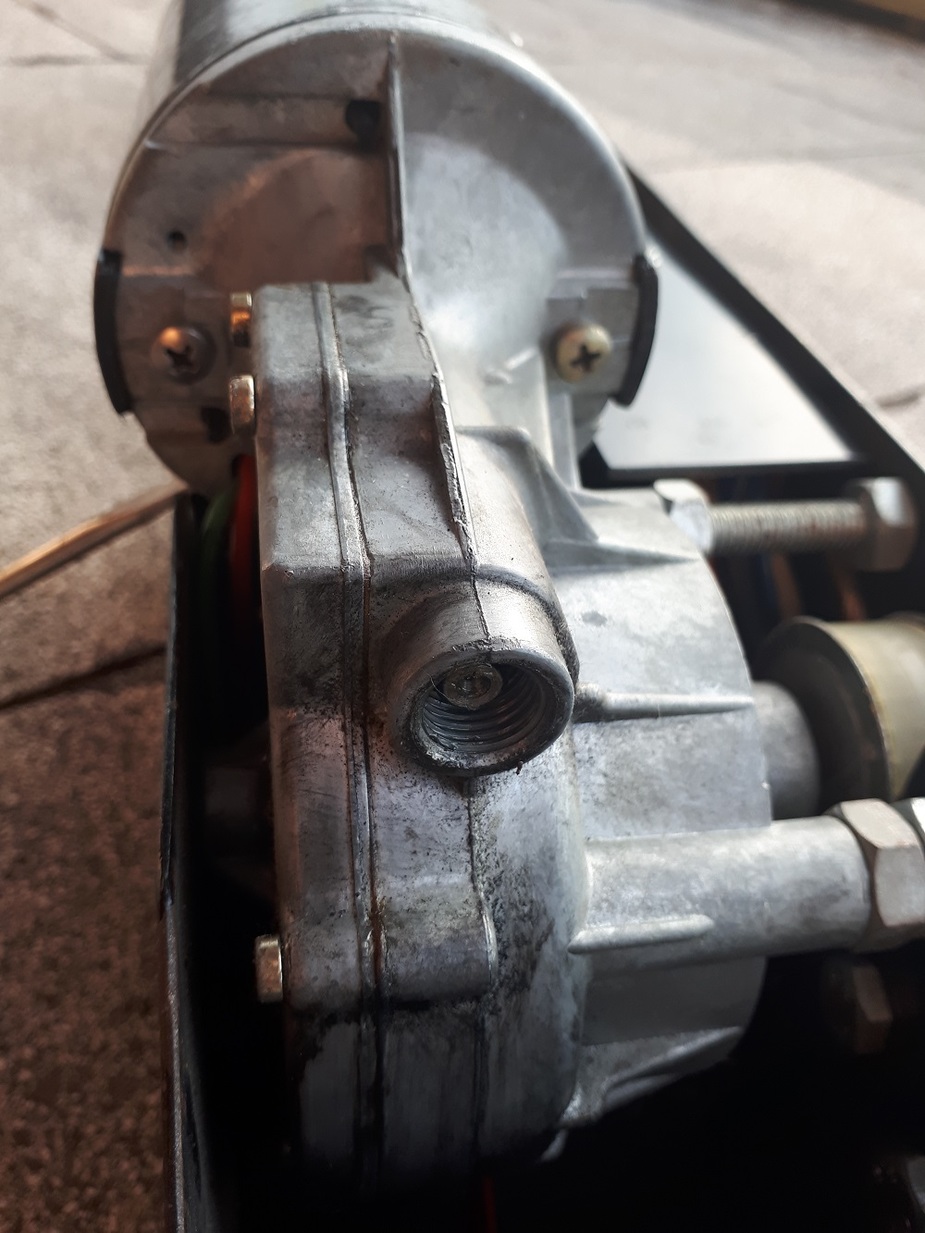

As a first step, any idea what the white screw-in plug does or prevents ?

Looked like an oil plug to me for a gear like oil lubrication, but opening it didn’t reveal anything.

All in all rather makeshift anyway, either a homebuilt or a prototype. At least by the looks of it.

Any ideas what to check to improve performance – or also about the make / model ?

I have a charger (industry standard from MASCOT), but no paperwork / docs at all…

thanks in advance !!

I would take it to some auto electrician-repairman to check if its carbon brushes are stuck,worn,burned etc.Another possibility could be a weak automatic disengager for the protection of the motor.