I can’t do that, on the (vertical) firewall and other vertical surfaces. For example for some weird reason the Socata foam on the other side of the rear luggage compartment wall is totally falling apart, and this started suddenly. I will have to get in there and scrape it all off and glue some new stuff on.

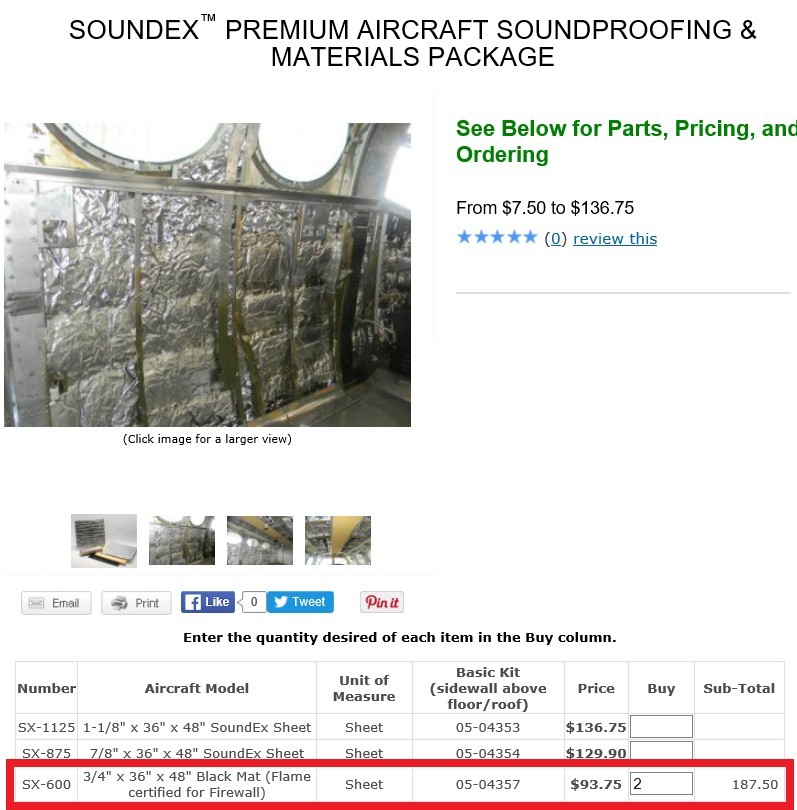

I use this:

http://www.woolies-trim.co.uk/p-1653-adhesive.aspx

For gluing under-bonnet foam pads.

But this:

http://www.woolies-trim.co.uk/p-1263-heat-resistant-adhesive.aspx

might suit you better.

That last one looks really great – thanks. I will buy a tin and try it.

Out of interest, does anyone sell this kind of foam in the UK?

Called the 3M dealer nearby this morning. This glue is special order with a minimum order of 20 units.

Peter, what material is this? I like to add sound proofing material onto the firewall engine side and looking at SoundEx SX-600 product from Aircraft Spruce. I am actually wondering, by how much it reduces noise. Let us know, once you have installed it.

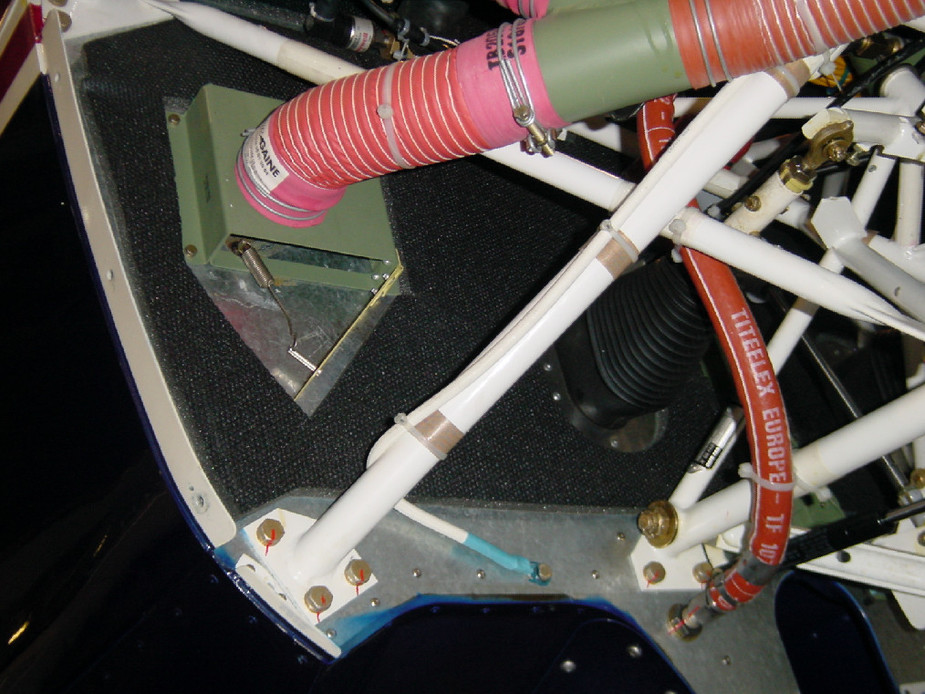

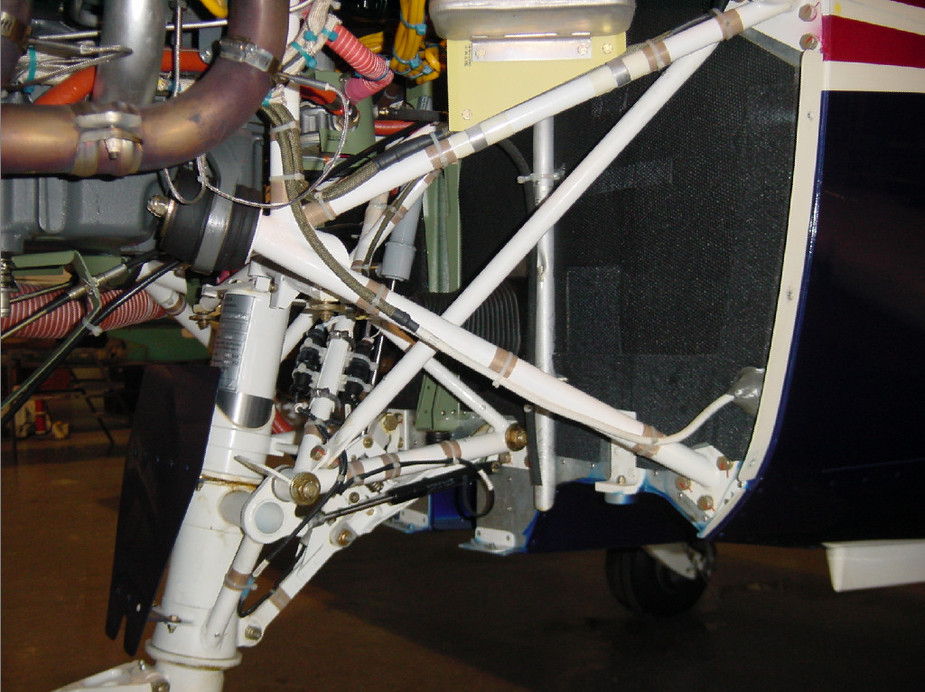

I suspect the extra quality material on the firewall will do almost nothing, because most of the cockpit noise comes in via the windows, especially the front one which vibrates like hell from the prop airflow. Also there is a limited scope for gluing the foam onto the firewall, since much of it is obscured by fittings

(Photos from 2002 when the plane was new)

But who knows… I don’t think anybody has ever tried it.

I just want to replace the crappy Socata stuff which disintegrates fairly rapily.

The other function of this insulation is heat loss. You want to minimise heat transfer through the firewall, otherwise you will get cold feet  That is also the function of the insulation at the back end of the cockpit, and mine is completely disintegrating there… you need to only touch it and it crumbles.

That is also the function of the insulation at the back end of the cockpit, and mine is completely disintegrating there… you need to only touch it and it crumbles.

I might get the 1/2" one, SX-500, for the firewall. I don’t have enough of the stuff I posted at the top to do both ends of the cockpit. The aluminium face on the foam should help with wind resistance which I think is a big factor in the disintegration of the Socata stuff. For example I noticed that the foam starts to disintegrate behind the oil cooler, where there is a lot of airflow. OTOH it may need that special glue they sell and they might not ship it outside the USA (I have an option to ship stuff to the engine shop and get it chucked into the box).

The photos at Spruce showing the foam were done in a large cabin class twin and there you have huge wall areas. To get at the walls in the TB20 would take a lot of trim removal. But it may have an effect.

Contact Adhesive is what you need.

Either a water based contact adhesive product like the one identified earlier (used to be called Fastbond 30) or a solvent based contact adhesive. I used to work at 3M in this field, and still have a few contacts that we could utilise.

Do you know the 2 different surfaces that you are bonding? Eg. Paint or metal to rubber or plastic.

1099 is a Nitrile adhesive for plastics with temperature limits of -40C to 121C

1300L is a Neoprene adhesive for high temperatures with limits of -21C to 149C.

For info – FB30 limits are -40C to 110C.

Make up a test sample to begin with to see how good the bond is. Clean all surfaces, with a good solvent, thoroughly prior to bonding for the best results.

Doing the Annual on my TB20 this week so a bit short of time to give you more info until this evening.

One surface is the rubber.

The other surface is either primed aluminium or the zinc plated steel of the firewall.

People use MEK to remove the old adhesive (from the Socata self-adhesive foam) which is really nasty stuff and needs a respirator.

This link takes you to the 1300L adhesive product info

link

For a supplier try

in Reading.

or

in Shoreham (I don’t believe it)

Don’t use MEK it’s nasty stuff, although it does work well.

For a cleaning solvent use 3M Solvent No.2 or a good paint thinners (not recycled gun wash).

1300L is used by most of the Aerospace industry from big British companies to the small ones. It’s actually used globally by the Aerospace big names.

Hope this helps.

The AF178 from Woolies arrived. I wonder, if I use it on the firewall, whether the stuff will never come off?

Also it contains toluene which is quite toxic and even though I have the full face mask (with carbon filters) for 2K paint spraying, I don’t fancy using this in the confined space of the rear airframe cavity.

So the 1300L one – thanks Colin – looks like the one to use, at least in there.