I always thought the early GT models had gas struts of 400NM.

I take it that it is only the bracket that is attached to the door that requires changing? The lower attachment point of the gas strut is part of the door hinge assembly.

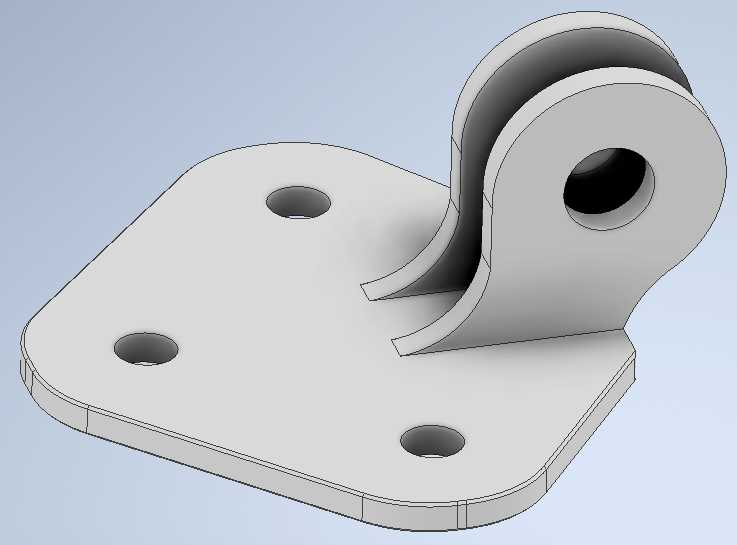

That is possible… The new bracket (above) is necessary because Socata could not get a 600N strut in the same length as the old one.

I also recall that some people sidestepped the expensive bracket change by gassing-up their old 400N struts to 600N, including on pre-GT aircraft (the pre-GT had constant problems with the doors coming down) and that would sometimes break the pre-GT door.

Yes the other end of the strut stays the same.

But Socata didn’t get it quite right and the new (600N) struts also have a bigger hole in them, so I had to machine-up bushings to reduce it. I gather most installers never bothered and the strut just “moves around a bit”

I have ordered two of these 400N Struts today.

https://www.techniekwebshop.nl/stabilus-gasdrukveer-l231-400n-ca047708-p1436931g-18-mm-6-2-mm-400-n.html

Yes; they are very cheap

You just need to find the right “end bits” and this can be a challenge, because Socata like to pick customised variants and then they do a deal with the manufacturer to not sell that variant to anyone else but them. Standard practice in aviation, done to frustrate concessions like this, but actually the practice is much older because in the US system you can do such substitutions anyway, in most cases of simple parts (because an 8130-3 is not required for a Part 91 N-reg).

Just got prices for the new door bracket.

TB10 25086103 FERRURE => 788.55 euros ea, estimated lead time : 87 business days at date of order

Plus shipping, plus VAT.

OUCH!!

WOW.

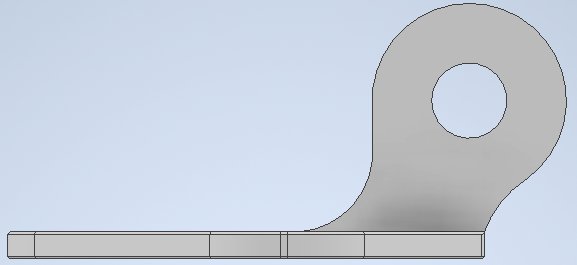

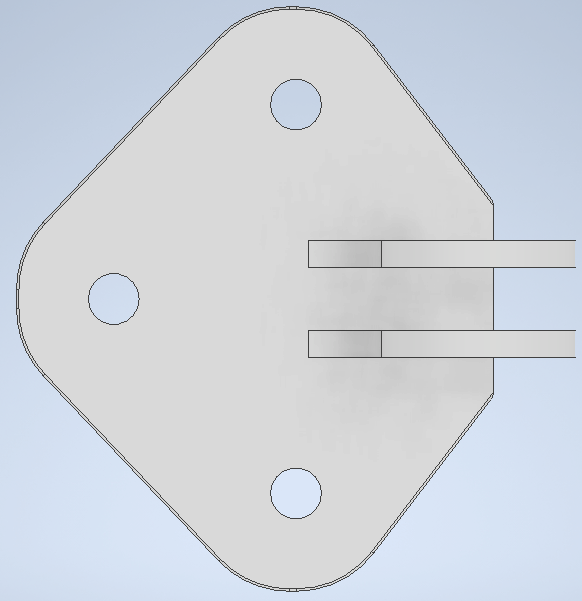

Well, I posted the drawing above

Any number of chinese CNC companies will knock these up for you. We could do a bulk buy… You could post it on the Socata owners’ group and see how long before you get banned

I just made an 3d-model of the drawing which Peter shared with us, and uploaded that to a 3d-printing service (metal, aluminum).

Polished metal (black): about 40€/pcs (Tolerance: +/- 1%)

Alu: 100€/pcs (Tolerance: +/- 0,2%)

WOW – awesome! Thank you

If you send me the model I will host it somewhere.

I’d use high tensile aluminium as the minimum. This bracket is under a lot of stress. 600N = 60kg. And you can work out the lever arm on that. Not sure printing will be strong enough. For $100 I reckon you could get a batch of say 10 CNCd in China.

Also add fillets in the obvious places e.g.

I did this a while ago but obviously there is almost zero stress on that.

I got already some printed parts in SS, and machined it → Very strong material! But I never tried Alu or “Steel”…