That’s quite an amazing statement!

Probably the reason is that there is no straightforward approval system for avionics, or actually anything involving electronics. The authorities just do not understand it. I am told that one big concession in CS-STAN is that anything described in FAA AC 41.13-1 needs no approval at all, but that stuff is basically metal bashing. For some “electronics” you need a US DER or EASA Part 21, no matter how trivial it is.

Peter wrote:

People have also built LED modules which replace the fluorescent modules on King avionics. Just emulating the display module is a fairly “surgical” approach. A firm at EGHH used these and then, some years ago, told me they can’t fit them anymore because EASA would not allow it.

It is possible to get these approved by EASA as a minor change, but there will be big fees and lots of paperwork involved.

I don’t know the answer (actually I doubt anybody outside King does, and this business is full of BS, spouted to justify silly repair fees) so one has to speculate.

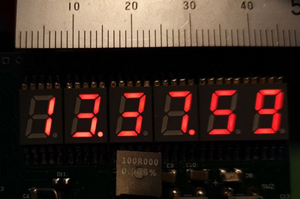

All these gas displays were custom made, because they were made with display elements as required by the instrument e.g. a KDI572 will have digits for the distance, digits for the GS, etc. A lot of LCD displays have been and still are made the same way; if you want a dirt cheap display e.g. for a €200 washing machine (parts cost under say €30) then this is how you do it, not a generic dot matrix unit.

Originally they were custom made for King, probably in Japan which historically led that market, starting with pocket calculators (I had a holiday job at Commodore in 1971 at £3/week  ). People definitely still make nixie tubes – super fashionable these days, along with valve amps

). People definitely still make nixie tubes – super fashionable these days, along with valve amps  And Itron, now Noritake-Itron still make this stuff. Wide temp range, etc. This component has been out of fashion for about 30 years and the volumes are small. Futaba is another old name.

And Itron, now Noritake-Itron still make this stuff. Wide temp range, etc. This component has been out of fashion for about 30 years and the volumes are small. Futaba is another old name.

The problem is that Honeywell/BendixKing (HBK) has been a dead company for around 20 years, so the volumes will not be small; they will be zero (just repair volumes), and if they don’t buy anything, nobody will make them. They would have had lots of stock though.

The way to approach this is indeed Ebay. The KDI572 has three key parts: the display, the driver chip(s), and the custom logic chip 120-08014-0000. The driver chips may still exist (not checked; do have the MM). The logic chip comes up on Ebay.

If somebody wanted to make a KDI572 properly, it would be trivial to emulate it. Sandel did it on the SN3500; I reckon it took somebody a few days to work it out. Same size box, plug-compatible, a nice LCD but actually you just need some small 7-segment LEDs

But then you need to certify it, because the homebuilt business is already full of extremely cheap and integrated stuff.

People have also built LED modules which replace the fluorescent modules on King avionics. Just emulating the display module is a fairly “surgical” approach. A firm at EGHH used these and then, some years ago, told me they can’t fit them anymore because EASA would not allow it.

Anyone aware of supply chain issues with the gas discharge displays used in most older avionics, and of especially the ubiquitous Bendix King units?

My avionics shop has told me that it is impossible to find replacements if they fail in any way (usually starts with individual segments). Having to find and pay for a complete KN572 replacement on Ebay, for example, is a costly solution if one can even be found and then who knows how long its display would last.

Peter wrote:

buy a unit or two on US Ebay

Thank you for this. I replaced the display but still had the same problem. I learnt something in the process, so the experience wasn’t wasted.

Luckily I managed to find a younger second hand one reasonably cheap and swapped the whole unit. The newer one has much better range, so I’m happy.

Peter wrote:

and there is no easy way to melt all contacts concurrently

Well, there is, but generally unless you’re doing this stuff often you don’t have tools (they aren’t cheap so you don’t tend to buy them on a whim!) But you may know someone who does – anyone who does electronics rework probably has a suitable desoldering tool that can do pin through hole a pin at a time, or a hot air gun for doing SMD rework. The main factor is the glass module (personally I’ve never tried to desolder a large soldered-in display module).

Although given the extreme pricing on aviation radios, it might actually be worth buying a good desoldering tool (e.g. Hakko) just for the job then selling it once the job’s complete…

Which King units have soldered-in displays?

Those which plug-in into that flimsy connector, yes. Some are soldered-in though, and there is no easy way to melt all contacts concurrently (one would have to make a special tool) so transplanting the display module involved carefully cutting the pins and then soldering the new display in one pin at a time.

90% of King display problems are due to dirt or corrosion on the display contacts, if you remove the display and clean the contacts with a fibre stick the problem usually goes away.