I have four Part M, stations within a 50 mile radius of me. Three of them I would not give an electric kettle to service. I have used three of them in the past. One of them I filed 16 MOR reports, after a truly shocking incident, where they let my tyres down, and placed a fire truck on the runway, to prevent me leaving. I had queried work done, and was intending with-holding part of the payment on my invoice. That, as you can imagine, ended in tears. That also was the incident where the local CAA inspector, whilst sympathetic to my cause, stated it was all my responsibility as owner/operator. This lot went bust two years ago. They also borrowed a prop, from an aircraft that was in for maintenance. to transit another aeroplane to a different airfield. The owner, would you believe, spotted his prop, at the other airfield, on a different aircraft.

The fourth shop, which gets a good rep, does not touch N reg. They are out of the picture therefore.

I eventually found a shop 156 miles from my base. These guys, however, are the ones who left the grips!!!!!!!!!! They also slated every other shop in the land. I could go on, but am gradually losing the will to live as far as maintenance goes.

I now have a roving I/A who is very diligent, good at what he does, and travels to me, or where the aeroplane is.

For the annual I fly two hours to my shop and stay there for two days – it never takes longer. The 50 h and smaller repairs I do at home.

That’s fine if you don’t have a normal day job.

Also, 2 days for an Annual on an SR22 is astonishing. It is possible if they put 4 people on it and there is never any remedial work.

Sure, 4-5 people do it, and since they do ONLY SR2x aircraft they are quick – and good,

Many people who do have a “normal day job” can get away for 2 days, once a year anyway.

Edit: Of course I am aware that this might produce high travel cost in many cases where shops don’t do annuals in 2 days. My friend’s 182 just came out of annual … after SIX weeks!

My experience has always been 2-4 weeks, depending on parts, for standard Cessna:Piper types. I would imagine that’s pretty standard.

That also was the incident where the local CAA inspector, whilst sympathetic to my cause, stated it was all my responsibility as owner/operator

That is terrible, but isn’t it the correct legal position?

Obviously it is nonsensical for the vast majority of owners who just trust the company and are not in a position to verify anything that isn’t blindingly obvious on a normal preflight check. I guess the legal principle is that if the owner is responsible, he has recourse against the company (or the CAMO – if they failed to pick up e.g. some AD?). But he can’t do that unless he is still alive…

My experience has always been 2-4 weeks, depending on parts, for standard Cessna:Piper types. I would imagine that’s pretty standard.

Speaking of the length of an Annual, for a typical complex SEP it is about 5 man-days plus paperwork. An indication of the paperwork is here. That assumes all service parts have been pre-ordered and zero remedial action and only the most ordinary lubrication actions – basically doing any grease nipples, plus a liquid lube on everything else i.e. no dismantling and greasing. If you are retractable and want it greased properly then it is maybe 2 days extra but that wouldn’t be every year unless you operate on grass/dirt. IMHO the long Annuals e.g. 4 weeks are caused by other factors, not related to your aircraft

But a post-maintenance check would be almost entirely a visual inspection – an hour or two, assuming the covers are already off.

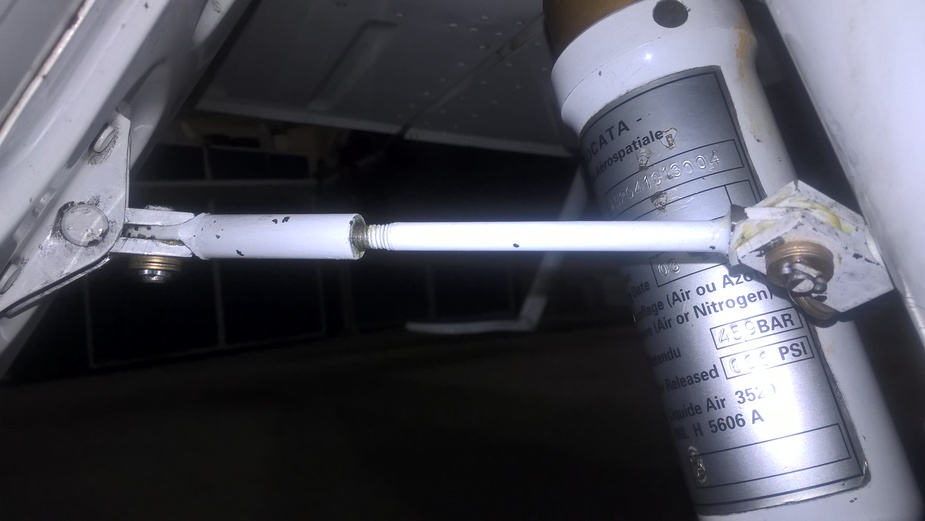

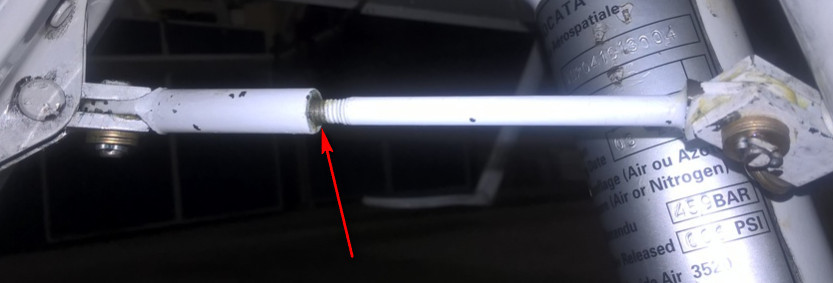

Another conrtibution to this thread is: when I wanted to get explained why I´ve been billed a Rod Pin and two hinge bearings while I found (for my impression) no new parts (except washers), no new rod pin and no new bearings replaced @ the RH Main gear (see pics) I´v e got the answer from the shop: “The new parts are terribly painted. The parts are brand new but the paint is not so nice. Maybe you noticed that the play on the gear door is completely gone now.” Honestly I feel messed about with this and this answer. The work was done on the main gear of a TB20 to reduce the play of the gear door…. Has anybody of you heard about a terrible paint quality of Socata exchange parts?

I’m surprised there is no locking nut on the rod assembly. Unless that is quite a tight fitting thread class, it’s going to wear.

First, ask the company to show you the EASA-1 forms they got from Socata and the invoices, to prove they actually bought them just now. However, I am sorry to say but Socata is well capable of this. I have had some parts from them which were years old and badly dented etc. And they built my new plane in 2002 from some new avionics and some returned avionics. It is called the Gallic Shrug and it is the way they work. I could tell many other stories…

Socata have said to one visitor a couple of years ago that they are no longer making custom-made airframe parts, and are processing e.g. ex-crash parts to fulfil customer requirements. They have subsequently denied that but it is probably true. However I would have expected them to repaint them, at least. They are not “badly painted”; they are parts from another plane!

Secondly, I see no grease, or virtually no grease, so this linkage will be shagged by the next Annual and you will be looking at another 2k-3k in parts.

Thirdly, “the play on the gear door is completely gone now”, they need to read the MM. There is supposed to be a specified play there, IIRC 5-10mm at the bottom of the gear door. The linkage is adjusted, on jacks obviously, so the door “just exactly closes fully up” when the gear is up. When it is fully up, it must not rattle, otherwise the resulting in-flight flutter will shag it in no time, and will shag the hinges which are another few hundred (I just had mine done). If there really is zero play in the gear door when the gear is down, the stress on the parts will be huge, during operation.

Make sure this thread is well greased

because it rotates slightly during gear operation. Very few mechanics know that, leaving it un-lubed and after a few years it seizes solid (rusts up) and then the bits at the end get shagged and they are about €200 each

This stuff is easy except for the completely brain-dead, and the key is good lube with grease (not oil).

Peter wrote:

Make sure this thread is well greased because it rotates slightly during gear operation.

An odd design but it explains the lack of a nut! Grease would certainly help reduce wear. Machine threads aren’t typically used for this purpose..