Clue: imagine the engine distorts the rubber mount slightly.

This might be a fairly typical IO540 installation.

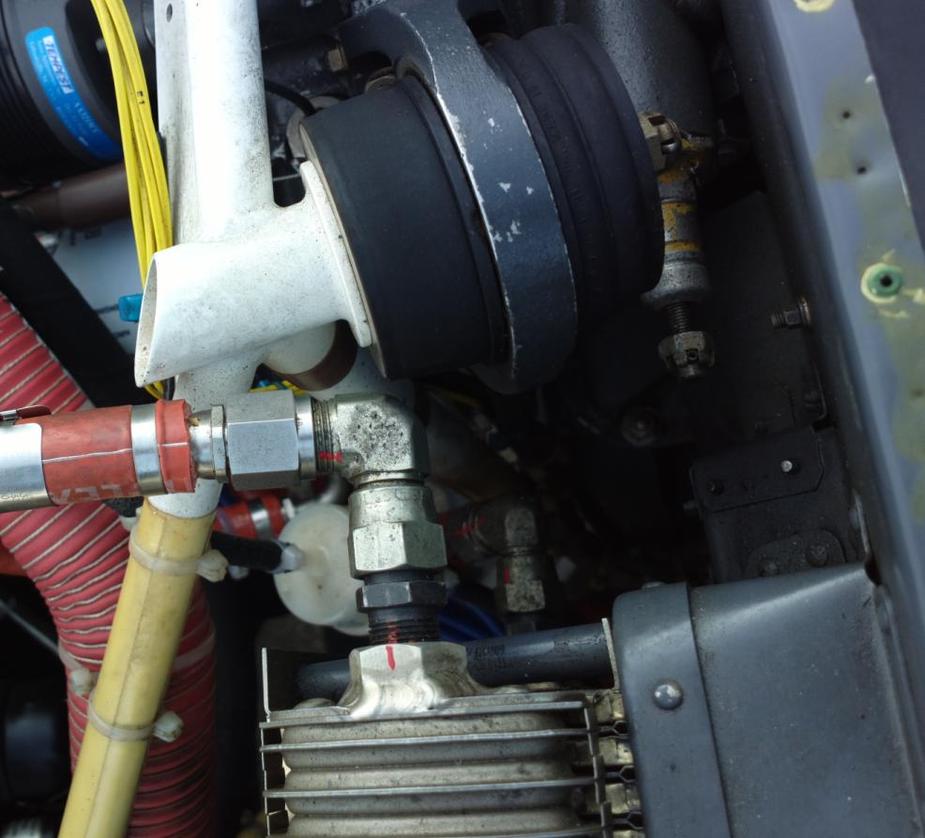

Too close tolerance to the oil cooler attachment? The red line on the oil hose attachment isn’t there either.

The yellow EGT/CHT probe cables should probably be attached better to avoid chafing but it’s hard to see in a 2D image.

Crossed with above post!

I see a bundle of yellow wires that can freely vibrate/chafe against the engine mount. Sooner or later the insulation will give way, and hopefully it will flip a circuit breaker.

[[edit: ah, achimha already said that, sorry ]]

During startup or shutdown, the engine shakes quite vigorously, and this gap closes up

There is a little bit of “give” on the oil cooler which has thus far prevented damage to the 90 degree fitting on the oil cooler, or something much worse like cracking the oil cooler fitting, but there is clearly contact being made between that and the metal disk of the rubber mount.

The oil cooler needs to be mounted a bit further “to the south”. Another 5mm would do it, but clearly somebody has been there before and there is no more adjustment left in its four mounting holes. The engine baffle (to which the oil cooler is attached) needs to have its holes “moved” 5mm along.

I wonder if any TB20 owners can check the size of their gap.

The yellow EDM700 sensor wires are actually OK. They could be done better…

I wonder if any TB20 owners can check the size of their gap

I am going to measure it on my engine one of the next days and take a photo too.

I have seen those hoses with a 90 degree fitting attached, like this:

Now it has a straight fitting, with an 90 degree elbow adapter, which gives less clearance. Don’t know if straight+adapter or 90 degree fitting is orginal, but for sure it could have more clearance with the hose end with intergral 90 degree fitting.

That elbow, Jesse, is a Formula 1 motor racing part, not an AN or MS part.

It is also aluminium. I would not use such a fitting on the engine oil. If that breaks, one is going down.

The original Socata fittings are steel and are much stronger.

The oil cooler mounting holes need “moving” a few mm, which is not too easy. One would not want to bend the oil hoses (hoses are much more likely to fail if bent away from their long term shape) so they would need to be undone, then the oil cooler removed, and then one can get to the four holes.

As it happens, I have photos from 2002, when the engine went away for a shock load inspection (pothole prop strike) and they show the same issue

but a slightly bigger gap. It may be possible to loosen and re-tighten the engine baffles, to fix this. But in any case the gap is too small.

That elbow, Jesse, is a Formula 1 motor racing part, not an AN or MS part.

That photo is to show the difference between the use a 90 degree adapter and a 90 degree fitting as I suggested, this part pictured is non aviation product, but these are available in both steel and aluminium for aviation use as well. Offcouse you need to use an AN / MS fitting for that, just don’t know that P/N from my head. Just inform at your local maintenance shop, and ask them if they can supply you with the correct hose / fittings. Some shops can make their own hoses and make it to the right specs.

http://www.aircrafthose.com/images/home_04.gif

See this picture with steel aircraft hose fittings with included 90 degrees corner.

Be carefull moving the oil cooler itself a few mm, these holes tend to crack anyway, as the oil cooler is quite some weight for the light baffle structure it is on, which is also exposed to vibration.

I do like that you document very your aircraft very well, which can be handy at some times.