Hello,

I bought this few weeks ago.

Not tested yet. I wanted to test it once before reporting….

Tom

http://kimgrity.com/other-c-59/ebdb20h-1272v-lead-acidlithium-battery-automotive-ups-battery-capacity-tester-p-424.html#.WJRV7zw8L7o

It looks pretty good. There must be a fan in there, to get the heat out – unless they feed it back into the mains but probably they aren’t doing that at this price.

Here’s a pic in case the link goes dead

Jesse – you should send your data to the manufacturers if/because their published data appears to be bogus. Same as I said in the other thread about backup alternators. It would be great to hear their responses to your measurements.

Yes I think there is fan inside but this comes with 2 big green external load resistors so the energy is mostly dissipated outside of the unit.

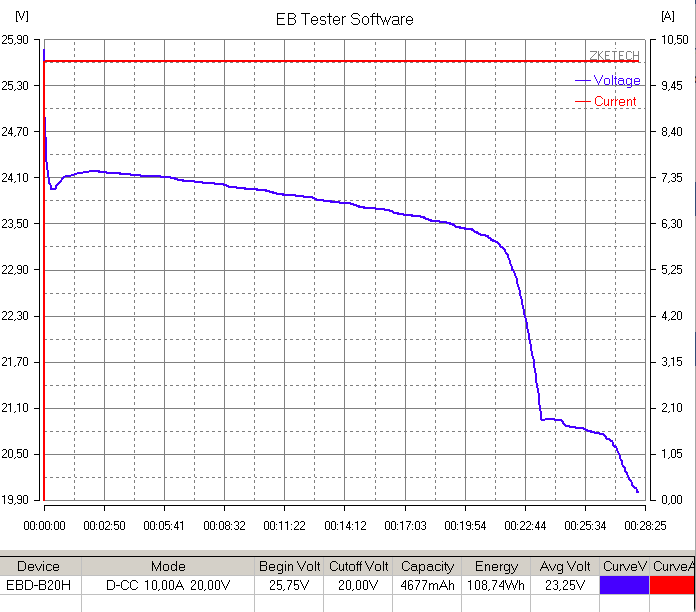

It comes also with a software to monitor and register the discharge.

Thomas.

Peter wrote:

Jesse – you should send your data to the manufacturers if/because their published data appears to be bogus. Same as I said in the other thread about backup alternators. It would be great to hear their responses to your measurements.

On these starters it is obviouse, and a normal why of specifying. This starter data is not incorrect, it is just not under a high load. How much you load it depends offcourse on how easy the engine rotates (temperature / compression / engine size / etc). They don’t allow repair and don’t do repair themselfs either. From what I understand from a converstion with Skytec a couple of years ago, is that they didn’t have an authorisation to do so themselfs (e.g. you will always get a new unit). At that time they said it didn’t make sens for them to gain additional certification and produce repair parts (only complete products where certifiable for them)

You see this quite often, some other manufacturers do this as well, as they don’t have an Part 145 organisation, therefore they don’t need repair instructions, and certification for loose components.

With the backup alternators, it is the same. They are basically unrepairable. So they just indicated buy new / exchange when you report such output. As all of those test are producing less then specified, while there is no damage noticeable, it seems like these products just aren’t up to spec. I can not say for sure, if there is anything wrong with these, as I never had a new unit for testing. All units tested, where units on which customers questioned the output. So it could be we only received broken units (although no obviouse damage).

Unfortunatly you will see this more and more. More and more manufacturers say that you can field repair there components / avionics / whatever. When it fails (because all products fail, you will get IMHO insane pricing for them to repair. The days of Bendix/King with excellent manuals and ability to repair for ever are gone. The quality of parts is going down for years.

For example, when you have an 1950’s magneto, or 1970’s starter, or 1980’s radio, you can keep servicing those. If they need repair it’s just something small. On these 1950’s it is rare to have to replace contact points, as there quality was so much better. Now you get new contact points, on which contact points don’t even align. Then your paying a high price, for such components.

On the 1970 starter, it is likely overhauled about 5 times, still with orginal bendix. When you buy a brand new bendix, there are parts which fail after a few starts. The design and partnumber is the same, yet the quality of the material is so much different.

When you do lots of these kinds of things, you can see issues, and that they changed something, because you never had an issue, and without changing anything else you will see failure which wheren’t there before.

On electronics they often only allow board replacement, or nothing at all. While for SMD parts you will need different equipment then for conventional parts, they still can be repaired and tested. For us this wouldn’t be a problem, as we have a small SMD line ourself, and also have the posibility to rework SMD. I think these repair fees from manufacturers are totally unrealistic. Units could be repaired in the field for a fraction if they would supply documentation.

From what I understand from a converstion with Skytec a couple of years ago, is that they didn’t have an authorisation to do so themselfs (e.g. you will always get a new unit). At that time they said it didn’t make sens for them to gain additional certification and produce repair parts (only complete products where certifiable for them)

Skytec want $400 for the overhaul which is uneconomic, but it is an available option.

Off topic; just answering above point.

I finally could test the EBD-B20H cheap Chinese capacity tester. It has worked fine and showed that the tested battery was bad…

Tom

Interesting why the battery voltage rises initially…

I don’t recall seeing that on the Concorde one.

I don’t know why, I’ll do the test again…

The end of the graph (at 23’) looks strange too?

Interesting that the RECOND light is misleading…

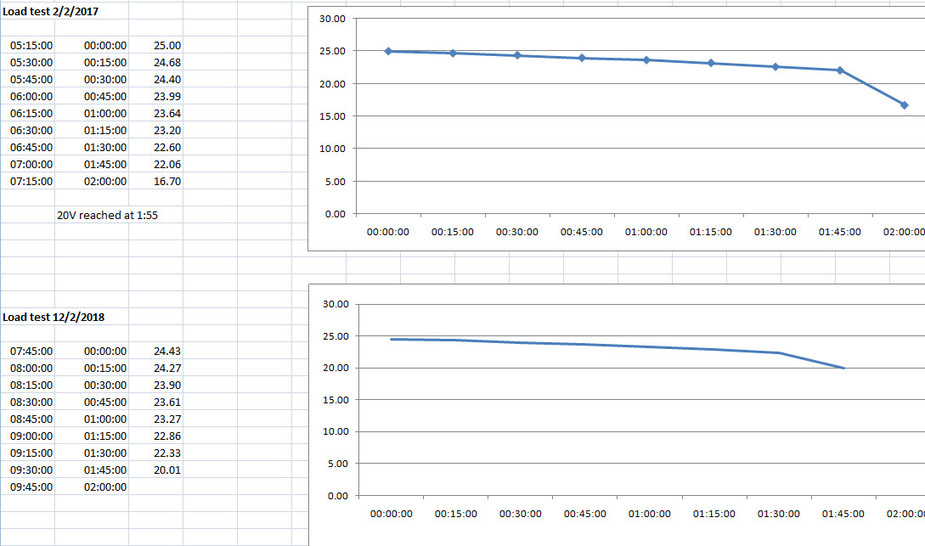

Anyway, here is the Concorde RG24-15 at 6 years (2.7 ohm load)

Not bad! Still passes the capacity test.

Peter wrote:

Concorde RG24-15 at 6 years (2.7 ohm load)

Don’t try that with a Gill …