Yes the master is on. Isn’t there a method where you put let’s say an 1A load on the battery and measure the time it gets depleted to a certain voltage?

How is generally a battery checked for health?

AlexTB20 wrote:

I have no idea, it’s the voltage reported by the JPI EDM930.

It’s on load (and probably a few amps – the alternator field coil will take ~4 amps on a 12V system).

Ask your local shop to run a capacity check on it. A good mechanic will know from putting it on charge as to how it quickly comes up, what voltage it holds etc as to whether it’s any good.

After a tip of say 1 hour (probably 30 mins would be fine) your battery should be fully charged. Remove the battery and take it home.

Then connect a known load such as a 50 Watt incandescent landing light across the battery terminals. Every hour you’ll use 50 watt hours, leave the load on and measure the voltage with a cheap digital Multimeter every hour. That’ll give you a much better idea than a battery shop as they just put a massive load on for 10 seconds and come up with a rough idea.

Do it one evening whilst watching TV. There are plenty of capacity graphs on the internet and there’s probably even a test like this in the Aircraft’s Maintenance Manual. Then obviously recharge the battery overnight.

Archer-181 wrote:

Then connect a known load such as a 50 Watt incandescent landing light across the battery terminals. Every hour you’ll use 50 watt hours, leave the load on and measure the voltage with a cheap digital Multimeter every hour. That’ll give you a much better idea than a battery shop as they just put a massive load on for 10 seconds and come up with a rough idea.

The capacity of a battery depends on the load. You can get more Wh out of it with a small load. So you should use a load which approximately draws the same current that the aircraft would use. 50 W sounds much on the low side.

According to Aeroelectric Connection, the “only” way to be reasonable sure your battery is in OK condition is two install two of them. Use the brand new as the main battery and the old as the second battery. After one year replace the second with the first, purchase a brand new as the first and throw away the second battery.

AlexTB20 wrote:

How is generally a battery checked for health?

With the caveat, that I do not know what the correct airworthiness test would be for certified battery in certified aircraft, and are curious to know the correct answer…

I can offer that for a lead acid battery when it is failing, its internal resistance goes up considerably, what this means is.

When on charge it will rapidly go to the voltage set by current regulator, say 14.something volts (or 28) and will then accept very little charge. Conversely when it has a load on it because of the internal resistance voltage will drop considerably, you may have trouble starting. Devices that have initial high current load may flicker, start slowly like your electric fuel pump etc. Landing lights take longer to come on to full power (engine not running), impossible to measure though.

This is for a lead acid batteries. If you have a amp meter this can help because you see how much current the battery will accept when charging, but it sounds like your battery is already gone, and you need a professional to confirm it and of course to find the cause.

Airborne_Again wrote:

The capacity of a battery depends on the load. You can get more Wh out of it with a small load. So you should use a load which approximately draws the same current that the aircraft would use. 50 W sounds much on the low side.

Indeed that peukert law, but the capacity is still the same at a given load. So if battery has 100amp hours, at 20 percent load and you take out 50amp hours at 5% load (which will less than half of the battery capacity at this much reduced rate), you will still have roughly 50amp hours at 20% load which is half.

Posts moved to previous thread on same topic. So now there is stuff further up the thread on battery capacity testing.

FWIW, here is an old article on checking battery capacity:

battery_analysis_by_computer_pdf

I purchased the CBA II nearly a decade ago and have been using it to capacity check my Concorde RG24-15 battery. The software has been upgraded over the years at no charge and the CBA II is still supported by West Mountain Radio, in that respect, even if there are newer models now available (with a corresponding price upgrade too

http://www.westmountainradio.com/cba.php

CBA_Manual_V2_pdf

I agree with @Silvaire about keeping a (Concorde AGM) battery permanently on a batteryminder, if possible. My hangar has restrictions on this type of semi-permanent connection, so I just visit the airfield once a week and have lunch while the minder is topping up the battery.

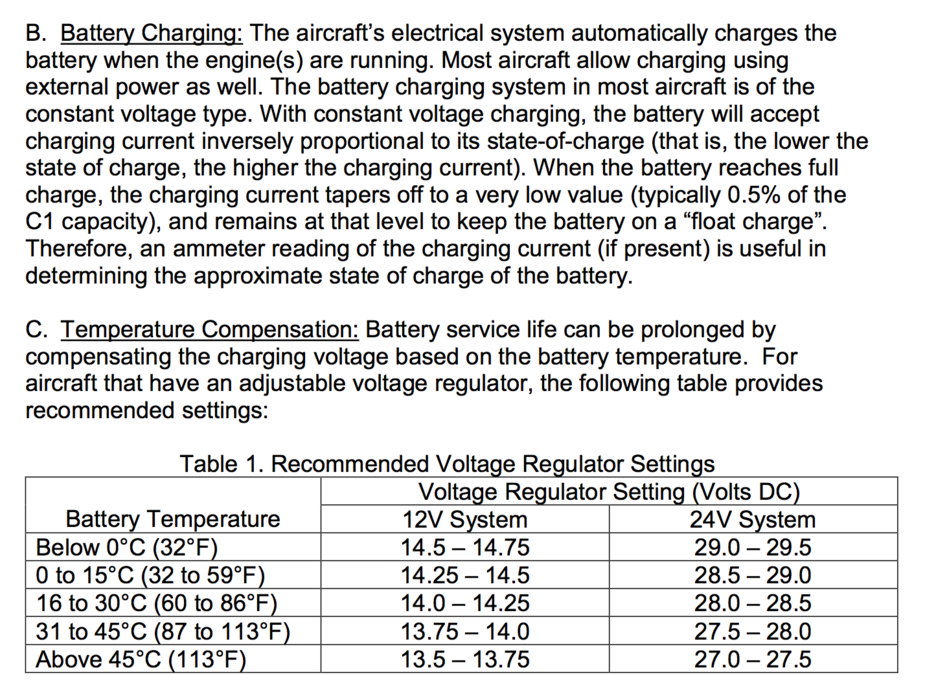

Perhaps a bit off-topic (?) is adjustment of the regulator charging rate during normal aircraft operation in an attempt to prolong battery life. The Concorde ref guide has a table indicating different charging rates based on battery ambient temperature. See p12 of the following document:

5_0324_rg_manual_rev_e_2018_pdf

This can be adjusted on my Zeftronics VR, but one needs to remove the seal/cover, turn a screw while monitoring the voltage, and then remounting the cover and sealing it. A bit tedious and not something one really wants to do several times a year depending upon the season. Any comments on how important it is to get this “right” on a permanent basis or said otherwise, how critical is it to battery life to adjust it on a seasonal basis? Or should one just set it to a compromise of say 28.5° which covers everything from 0-30°C battery temp? My battery is at the rear, so ambient is not affected by engine compartment temp and would normally reflect meteo temp reports.

This is interesting but is impractical since nobody will be adjusting the bus voltage according to the time of the year, especially as (as you mention) the battery voltage is probably not all that dependent on the time of the year.

The difference between the top and bottom of the range (say 27.25 and 29.25) is huge and if you try to charge a battery which is say +35C from 29.25V you will be heavily overcharging it. The normal enroute draw should be perhaps 0.5A but it would be a few amps instead.

A temperature compensated regulator, with a sensor in the battery compartment, would be the only correct solution, but AFAIK nobody in GA does that.