Don’t worry A_and_C – I already know that all these areas are 100% perfect. For example, the rear spar attachment fittings were removed, light surface corrosion polished out and new Piper parts fitted. See below before the new bracket was fitted………. Ditto all the other areas you mention were checked when new perspex windows were fitted, also the tail was removed as part of the respray. I know exactly what you mean and I see this corrosion (rear wing spar attachment) on virtually all old Pipers.

However, on the flap brackets can anybody see why not to zinc plate them prior to painting?

Thanks all. The flaps came off for the bare metal respray but I think I’ll have a look with the borescope now. You have made me stop and think .

My guess you won’t like what you find, also take a hard look at the steel to aluminium fittings, that’s front & rear spar fittings in the fuselage fittings at rear of baggage bay. Footstep internal fittings. Fittings at top & bottom of windshield and finally the fittings that hold the stabiliser bearing blocks just fwd of the rearmost frame.

Thanks all. The flaps came off for the bare metal respray but I think I’ll have a look with the borescope now. You have made me stop and think

Peter wrote:

All epoxy primers I have ever used were not UV resistant and after a few months in the open the stuff just cracks up

They are primers. You’re not supposed to use them without a top coat on outside applications. Within the structure, there is barely any UV lighting, so they’re fine there.

Stainless steel is not the answer, it is very bad news when in contact with aluminium

We’ve done this one before. Not sure it is completely as simple, because Socata use SS rivets extensively and mostly they don’t corrode or cause corrosion.

But sometimes they do although the trigger is not clear – apart from some owners tying the yoke to the seat to lock the controls, which prevents the drain holes working

I’m about to experiment with cerakote on some of my vehicle parts and to see how it fares.

Archer-181

Stainless steel is not the answer, it is very bad news when in contact with aluminium and I have almost given up using it.

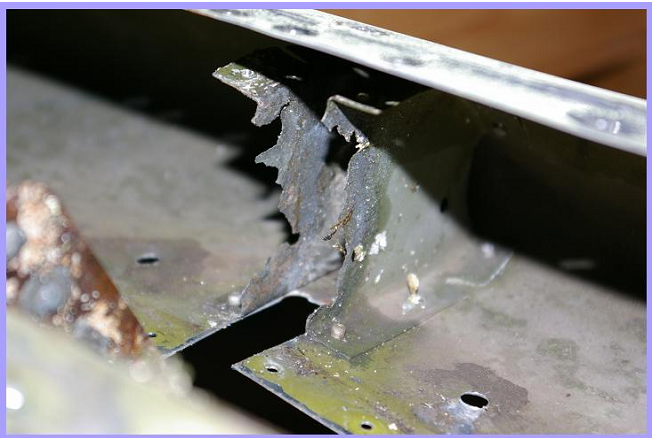

I too had a similar experience with my PA28 as wigglyamp did……… just see the photos

All epoxy primers I have ever used were not UV resistant and after a few months in the open the stuff just cracks up. One needs to at least UV lacquer it; same with almost all paint systems.

Archer-181 wrote:

I am tempted to strip it off, have it zinc plated, and then epoxy primed. At least this provides a sacrificial anode.

I have made good experience with AkzoNobel 463-12-8 Epoxy primer and with MIPA 100-20. 436-12-8 is best sprayed, but for 100-20 you can buy roll/brush hardener. For spraying the primer, you don’t need a too expensive spray gun though.

“ The rest of my flaps are in good condition. They were removed for the bare metal respray and get treated with ACF50 . This is light surface rust on an otherwise fairly newly resprayed aircraft.”

I thought the same when I bought a PA28-180. During the annual a year later, we got a boroscope inside the flap and the nose ribs where the steel brackets attached were completely shagged – it was a wonder we didn’t lose a flap in flight.