Suitable for 3D printing: https://www.dropbox.com/s/nmamnwz7jt3n51r/static%20plug.STL

@ Lucius

" For some reason, the owner of the Socata type club ignores me "

He (Andrew) does not have them in stock and does not sell them. There is another American TB-owner on that forum who produced some for friends as I remember ( copy of the Socata original maybe) but he doesn’t make a living with that and may have “run out of stock”.

I manufactured some out of drilled waxed paper bag carry handles that fit exactly into the holes per diameter and is pliant enough to follow the internal upward (no water enters) bend of the static line. Then I glued a small stripe of light thin red ribbons to it – it’s perfect. The red band on your photo seems a bit heavy to me – a strong wind when parked outside may rip it off.

No mouse will ever enter there

Thank you pshz!!! I will print it out, test it, and report back!

Thank you nobbi! I contacted Mike, and he said that he had given them all to Andrew. He may have run out of supply. You said that your plug is flexible enough to bend upwards. Is this needed? I would think that nylon, or even ABS is soft enough to just seal the port. Now that pshz has shared a 3D STL file, I will print it out, perhaps trying different plastics and report back.

I’ve changed base of the part. I think, the last one will be more onvinient to attach remove before flight tag (but, perhaps, more complicated to print)

https://www.dropbox.com/s/33p1e76nuhgkq8c/static%20plug2.STL

Lucius , I don’t know the original ones. My plane came without them – perhaps no bugs in Old England

I think it is better to have them made a bit longer, i.e. going up the static line for about 3/4 " helps to secure them in place in strong wind conditions.

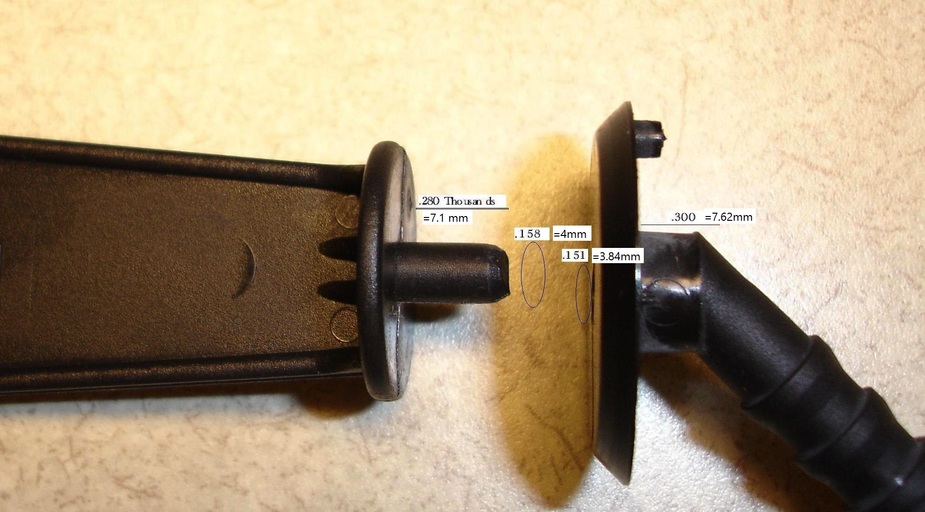

Nobbi, the original is in the photo above. It appears to be nylon and is flexible, so it bends around. However, the plastics usually used in 3D printing are either ABS or PLA. They are not as flexible, and won’t bend around. So the “cone” has to be shorter.

I updated the dimensions slightly by making it shorter.

The one that Mike Schutz creates is also shorter for the same reason:

Why not print a mold (inverse) and then make the part itself from more flexible material, (silicon or rubber based) using the printed mold?

i think the large red “tails” are worth having because it makes the plug very visible.

It’s true that wind thrashes it around, however. Some people have solved that by having a suction cup at the end of the “tail”.

I would be surprised if the very short parallel pin shown above stayed in the hole. There is nothing to hold it in. The plugs I have are tapered – as well as longer and with the (approx 45 degree) bend.

Jesse, my thinking was to design a 3D printer blueprint file (STL file), then have folks print it online in your favorite 3D printing shop. This way, you can pick your favorite plastic (and color), and have it shipped in a few days for little money. I am not sure, if the infrastructure exists for injection molding.

My hope is to have an entire set of small aircraft plastic parts done this way, starting off with a simple static port plug, as a starting point to get the ball rolling.