44 years at one hour per month at 50% power… :)

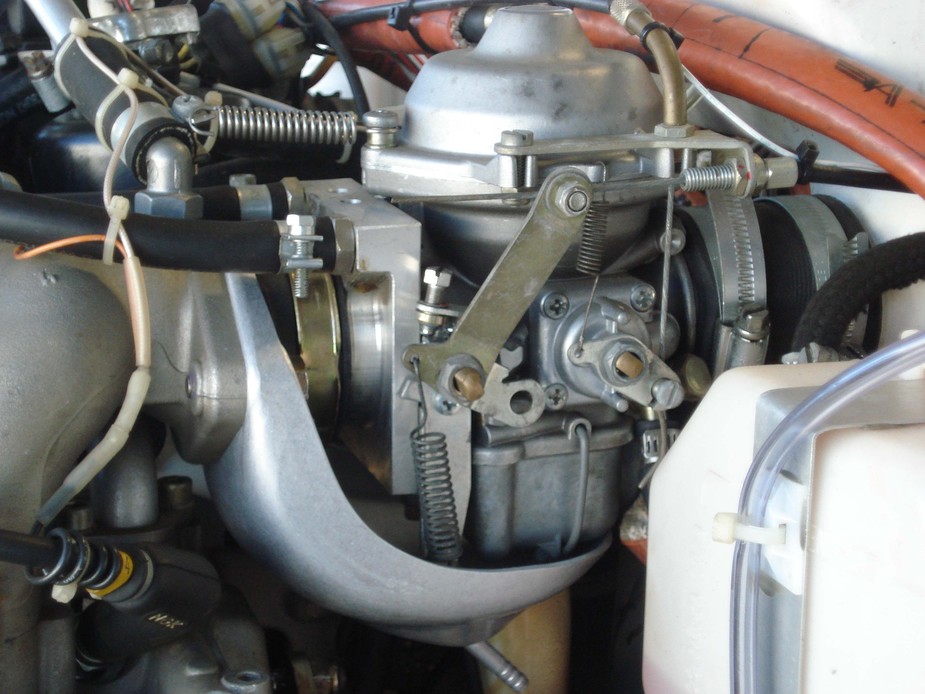

rotax 912, for me, has a lot to improve, there is much confusion and bad finishes

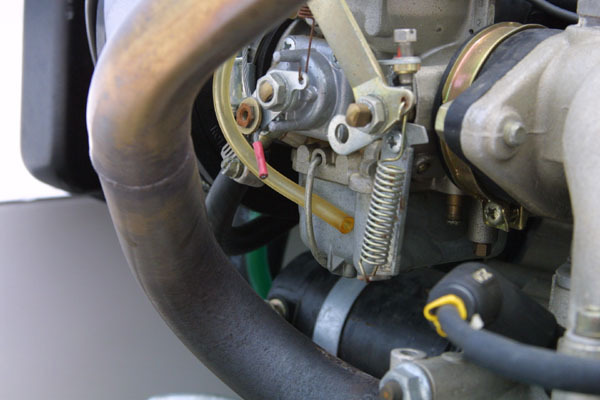

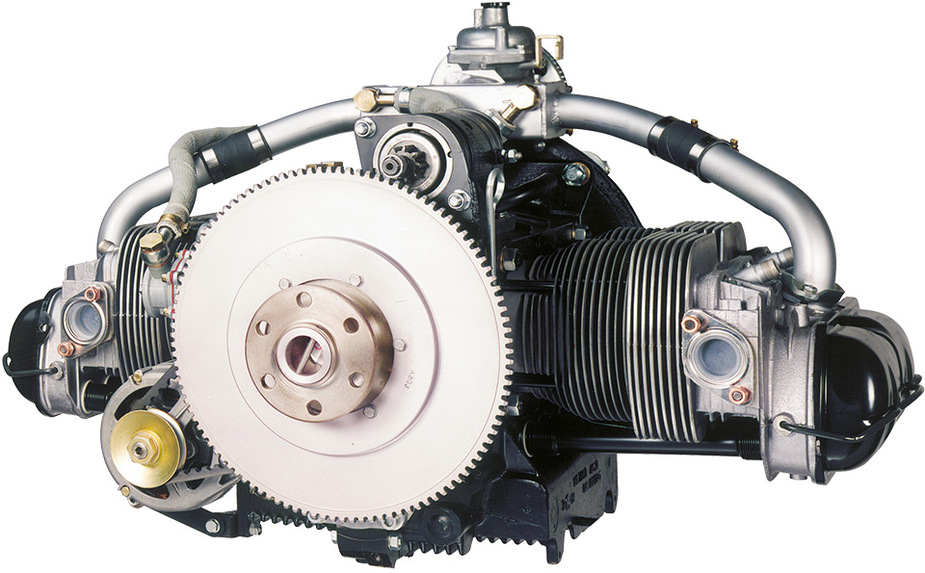

Who designed put the carburetors above the exhaust?

The carb location results from using side draft Bing motorcycle carbs, which are what was available in Europe at reasonable cost in the mid-80s. Given their bulk I think they’re located ‘out of the way’ as much as space allows, in other words behind the cylinders to the extent possible. The Rotax designers weren’t dumb, they were just working with what they had. Another issue with this carb location is that it doesn’t allow for gravity flow from tank to carbs, despite that being the situation on the BMW motorcycles for which the carbs were developed. A single updraft carb under the engine is the traditional aircraft solution and it’s better for fire protection and for gravity flow, although probably not as good for power output.

Shorrick, my O-320 has averaged about 2 hrs per month over 44 years, and (obviously) runs very well at full power. The man who owned the plane for 30 of those years didn’t fly it much due to overseas travel, but as a technical director of a European auto manufacturer he knew how to maintain an engine. It doesn’t leak a drop of oil to this day.

I’m not against the carburetor

carburetor, = gasoline and just below the exhaust

Is this a good design?

solve the problem

put a tray under the carburetor

And the spring that holds the carburetor?

“this is not serious for 20.000 euros”

this is not serious for 20.000 euros

Unfortunately when you look at the modern aircraft hardware, quite a lot of it is like that.

One EASA66 guy I know says that the biggest problem is not stuff coming off but constant corrosion which eats away at the plated steel parts, which need to be changed at the Annual.

On the Lyco stuff they use cadmium plating, which is banned (in Europe) outside aviation/military, but which is a lot better. On Lycos you see 30 year old brackets which are only just slightly rusty. This is one negative aspect of using parts from non aviation sources… it corrodes fast.

This is very bad also

I would possibly do that on my lawn mower, but not in my VW.

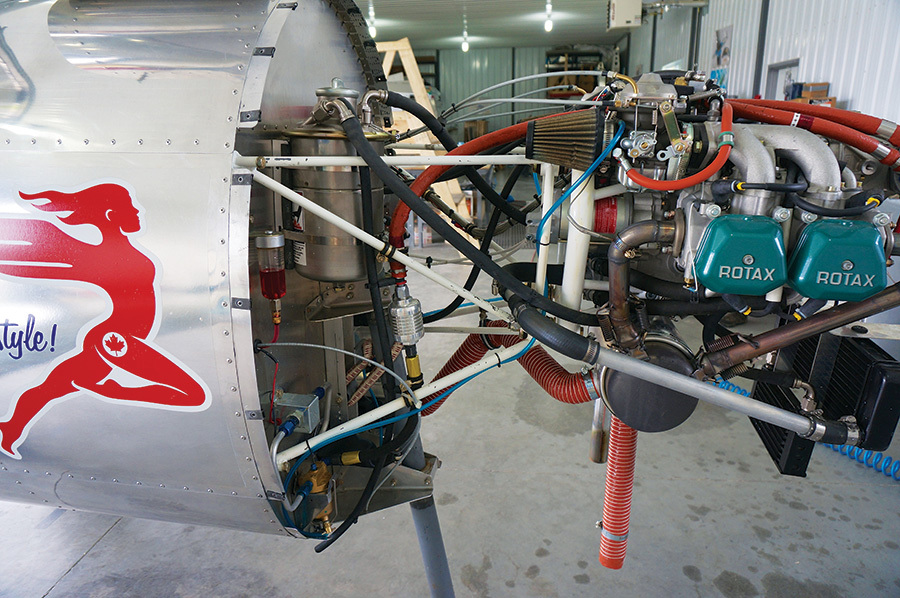

@celtico: the location of the exhaust is determined by the airframe designer, it is not fixed in the design of the engine. Rotax leave lots of liberty to anyone using their engines: on mine for example, the oil tank is below engine height where most installations have it more or less at the same height. The result is I can check oil level without having to rotate the prop manually until the famous gurgle comes up.

I agree with you that placing the silencer under the carburettors is not a good idea, but do not blame it on Messrs Rotax.

BTW mine is close to the rubber blocks damping the nosewheel vertical swing – not ideal, either…

carburetor and under the “exit” exhaust

if gasoline goes out of the carburetor, you have a big problem….

this is a not good design…. The hottest area, and over gasoline

I don’t think Peter would be amused by the tie wraps restraining (certified) MT electric propeller motor power wiring…. on the outside of the propeller hub rotating at 2700 rpm! Be assured they use only the highest quality commercial tie wraps

Back to the Rotax… Has anybody ever been to the factory and seen them building up the needle bearing crankshaft assembles? It’d be interesting to see. When this was a more common practice, say late 70’s on Japanese or Italian motorcycles of that era, it was typically done by ladies in the factory with a truing stand and a fairly large lead hammer… Apparently they were very good at it but it was still a very labor intensive practice manually knocking the crank segments into precise alignment. I imagine Rotax went down that road because in the 80s they were building a lot of two strokes for any number of applications, and two strokes used that kind of crankshaft.

yes

It is not the installation, All engines are equal

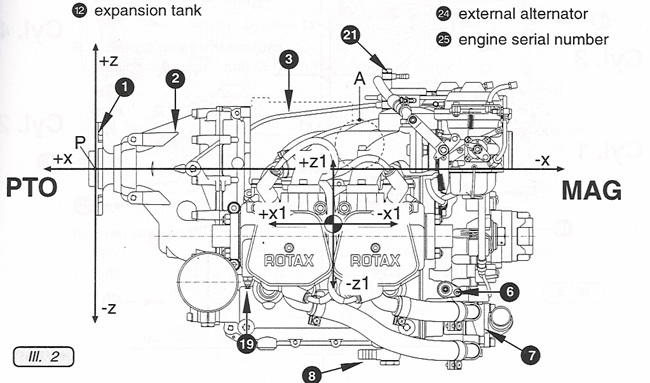

web rotax

picture nº 3

http://www.flyrotax.com/enginesImpressum/product-rangeImpressum/carburetedImpressum/912-100hpImpressum/pictures.aspx

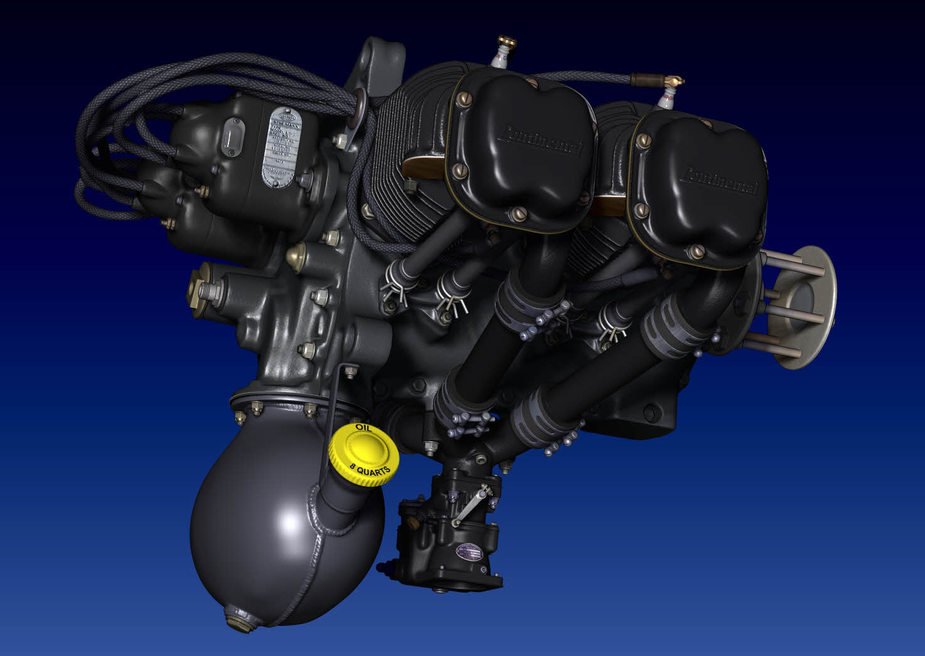

in the Verner engine, the carburator They are out of the heat

limbach

In the rotax 912, You have the carburetor 15 cm near the fire exit .Bold “good desing”???

Celtico, here’s where you locate a carburettor if you want to keep fuel away from and below sources of unwanted ignition. They figured out how to do it in 1937