Peter wrote:

I think the 48kt is Vs2 i.e. full flaps. 70kt is probably close to Vs0 for a C172. The TB20 Vs0 is not much above that.

No, it is Vs0, i.e. flaps up. OTOH, I checked again and it is 53 kt calibrated airspeed which is more relevant to the discussion. The TB20 has among the highest wing loadings for a SEP — about 70% higher than the wing loading of a C172. (Of course this is what makes the TB20 such a good IFR tourer.)

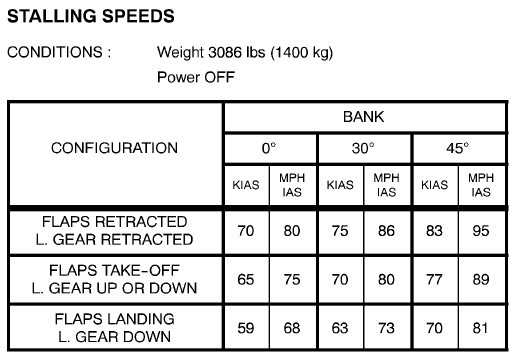

The Vs0 for the TB20 I’m currently training on is 64 KIAS. How come Peter mentions above 70 kts?

In level flight, Vs0 is 70kt according to this table

So the actual stall speeds reported in post #128 are about right.

Believing my Vs0 is higher is probably why I am still the mod here

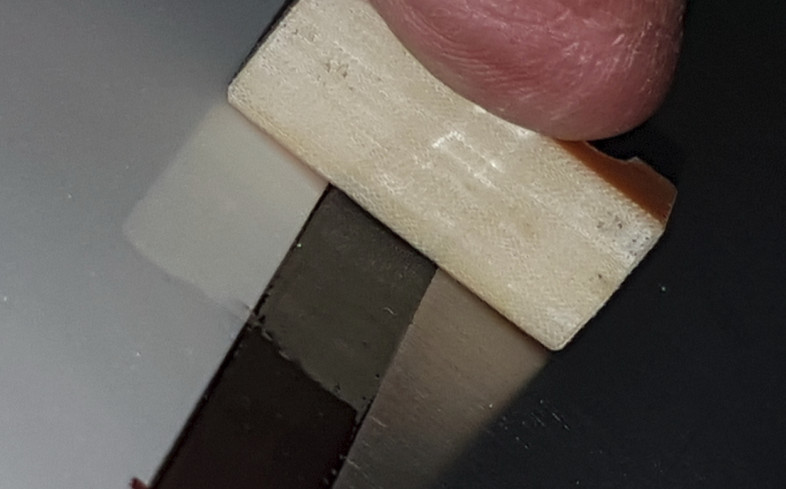

This is what I tried to achieve. In fact it is hard to do in one pass due to the sealant slumping. This particular bead (6-7mm wide) had a second pass to make it flat (non concave)

Whether it makes a big difference, nobody knows. We don’t seem to have aerodynamics experts here currently

The other day I spoke to a former Mooney owner and he said Mooney offer the same model with and without TKS, and there is a 10kt speed difference. I guess the wing is thinner, and with a metal wing you don’t have the option of recessing the TKS area to enable the leading edge to be maintained (like you have in a composite wing on say a Cirrus; I was told by CAV that the resulting wing-panel interface there is complex and the panels are very difficult to remove if damaged).

I have a theory for the 5-7kt speed loss reported by many TB20/21+TKS owners:

On the elevator, you have this strange deviation on the TKS panel from the elevator centreline

Nobody knows the reason for this. @pilot_dar may know where this assymetry comes from.

CAV supply a template to get this right, but as with all their other templates it was made from some 30 year old drawing and doesn’t quite fit. Also one isn’t quite sure how much to trust it, given that they supplied a template for the wing panel positioning which was for a different aircraft and didn’t fit at all! The same happened to someone a decade ago and on that occassion they located the right one, but for us it never arrived; fortunately the wing panel positioning was pretty obvious.

So I took great care to make sure the two elevator panels were angled the same way

If they weren’t, you get a twisting moment generated and a seriously out of trim aircraft which then needs aileron trim tabs to be bent and once you start doing that, you end up with a plane which might fly straight, just about, but it will be slower.

It’s quite tricky to get them the same, while doing the rivets. You need at least 2 people.

If the two panels are angled the same way but deviate from the design, you should just get a very slightly different trim position, which is OK.

Probably the same applies to the wing panels – they need to be identically located too.

Congrats Peter, a job properly done. Now you can punch trough layers without having to worry, that’s where it’s for.

As to testing, yes better done stationary. You may note though that the panels will continue to weep, even for a few days.. Also, don’t forget to do it every month as a minimum. Prevents air from getting into the system and prevents clogging up of the tiny holes.

As to stall speeds, I was taught that Vs0 is the stall speed in landing configuration and Vs1 is clean. But that was a long time ago, maybe things have changed ?

Thanks

Shows how much I remember from my exams

And Vs2 is the stall speed at some specified config.

Probably a final update:

I gave the system a real test today, in IMC at -3C. I was being kept there for about 20 mins due to other instrument traffic, so this is a good case scenario. Ice building up at about 1mm per minute, disappearing immediately when the DE-ICE setting was used. Very nice to see!

After landing, there was no fluid at all on the underside (wings or hull) or the roof, but there was some on the upper wing surfaces, especially towards the training edge (flaps and ailerons). So it doesn’t make much of a mess, provided you turn it off at least say 10 mins before landing (not always possible of course). Flying in cloud above 0C also gets it off nicely, especially off the front window.

The spray bar really floods the window, enough to ice protect a plane flying behind you  That’s why it is push button operated; it sprays only when you hold down the button. The rest of the time you get the mist off the prop TKS feed which is plenty sufficient for normal stuff (I had that bit since 2002).

That’s why it is push button operated; it sprays only when you hold down the button. The rest of the time you get the mist off the prop TKS feed which is plenty sufficient for normal stuff (I had that bit since 2002).

Nice first run !

I hope we ll have the chance to read other reports.

The fact you can compare the system efficiency with the 10+ years flying without, is just priceless !

One thing which occurred to me is that with the full TKS system one has to avoid going to grass runways on which the grass is tall enough to reach the propeller. On a TB20 this would be 15-20cm. Admittedly that is a “runway” in an atrocious condition but I have been to quite a few like that in the UK (it’s the standard “farm strip scene” after a bit of rain and a bit of sunshine) and I would never do it again because all the leading edges get covered in extremely sticky fine grass cuttings which are difficult to remove. I reckon there is potential for bunging up the tiny holes.

Even if the runway grass is short, the parking might not be. There are loads of places all over Europe where you are forced to park on grass which can be 20cm tall. However in those cases I try to get help and move the plane manually (takes 3 people on grass) due to the risk of potholes.