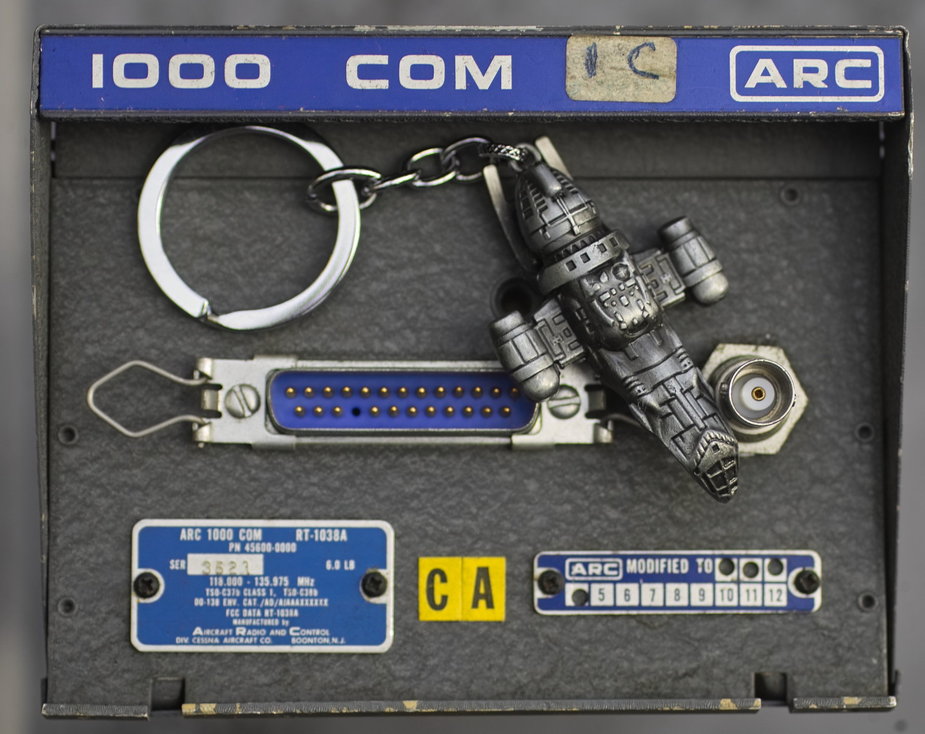

Here comes a pretty piece of solid American craftsmanship, hand soldered, hand wired, hand assembled… A Sperry (or Cessna or ARC, depending on the year of manufacture) 1000 Com unit. There are two pieces: A small control head for the instrument panel and a large box which lived in the avionics bay. These were original fit in a 1979 Cessna 421C that we bought in 1992. The radios needed to be replaced (still in working order) ca. 1996 or 97 because they could not legally be extended to the (then) new standard of 760 channels, before that it were only 720. In the US they sold a conversion kit, but this was never approved in Europe.

BTW: I only keep these in my garage for Jan Olieslagers, otherwise I would have thrown them away years ago. We will find a way to get them to you…

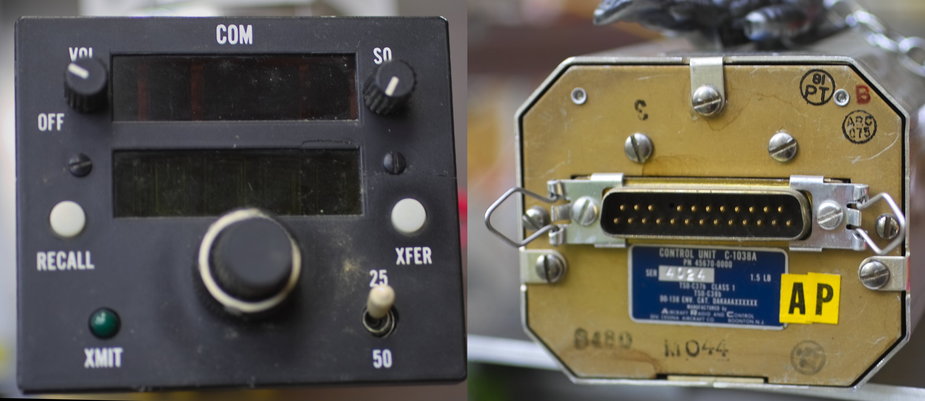

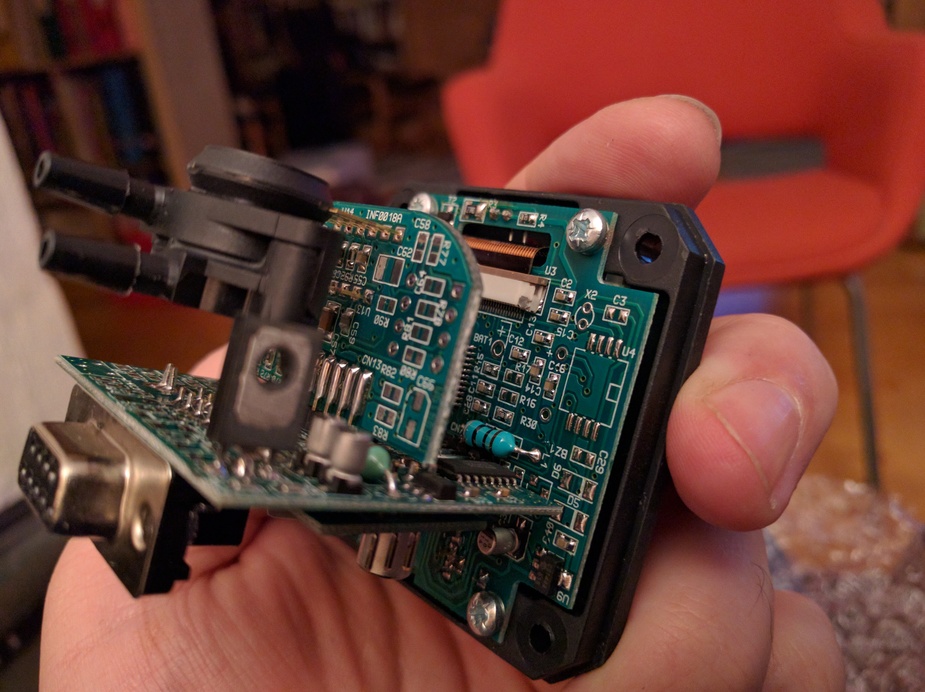

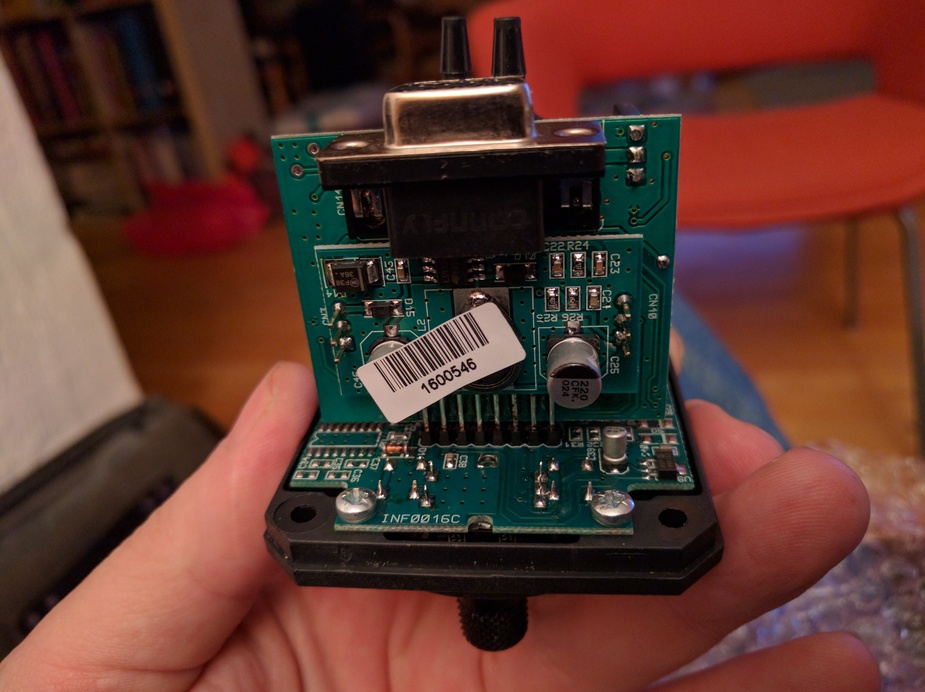

The control head (front and rear):

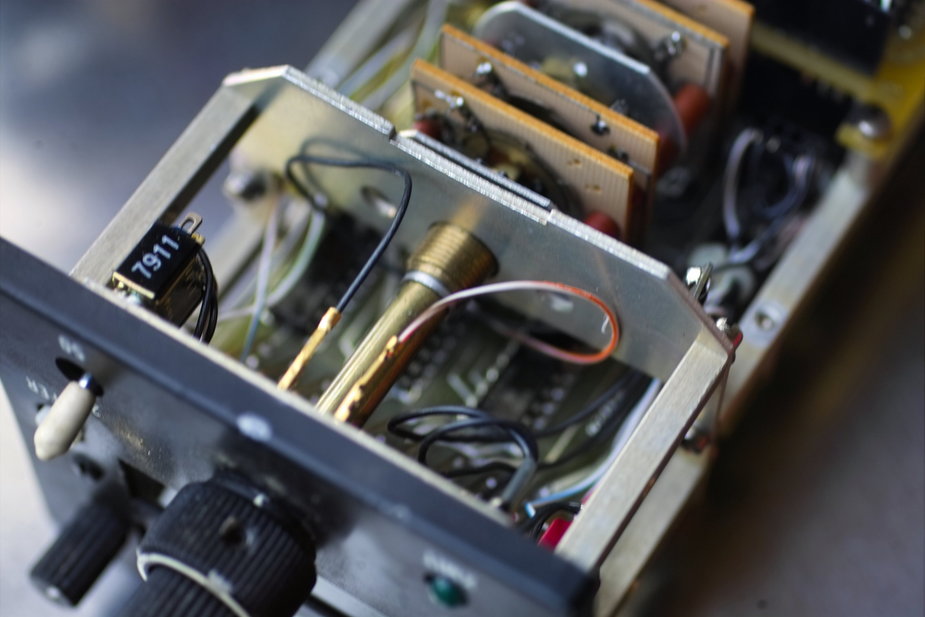

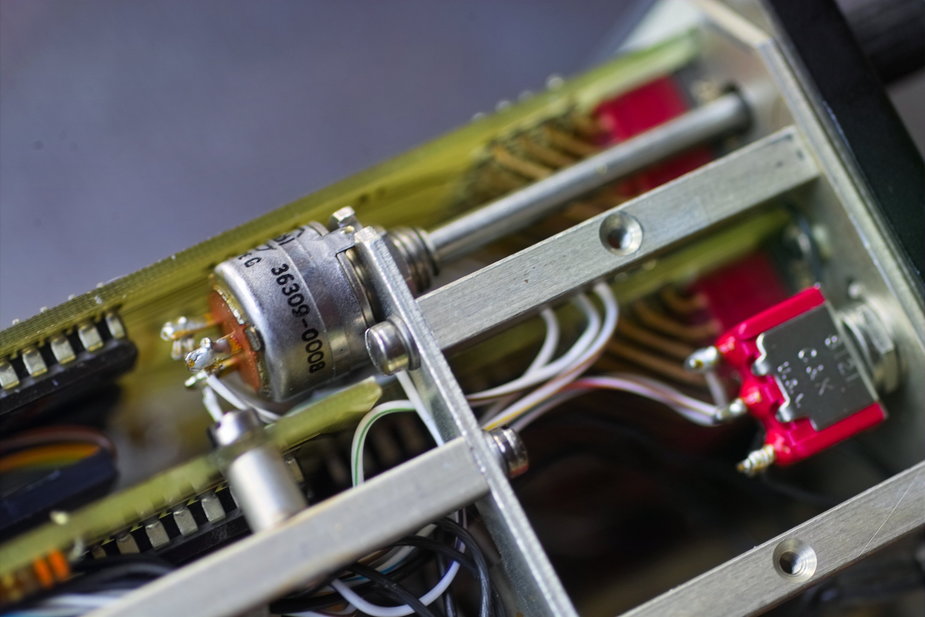

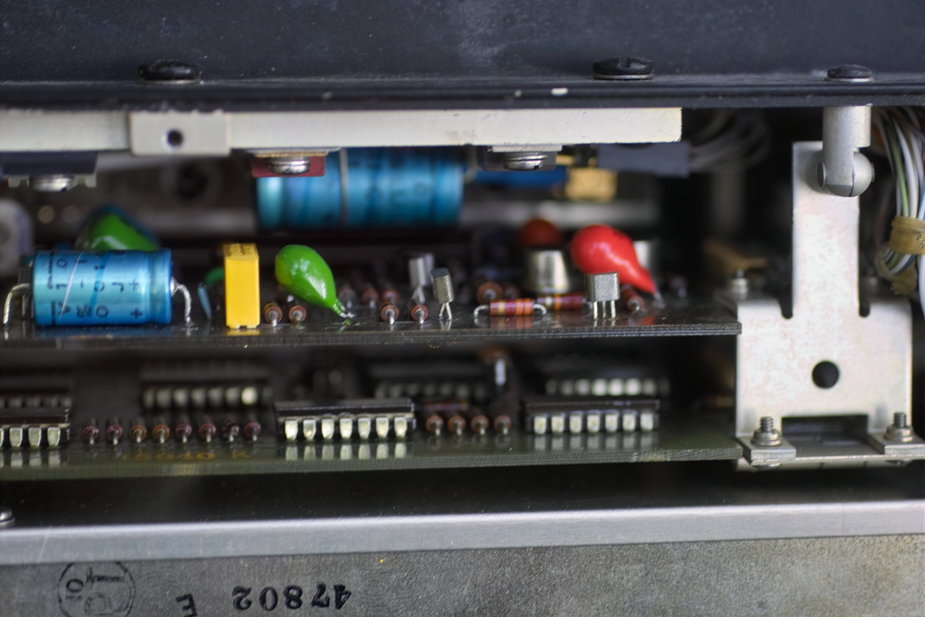

Inside the control head (no sockets and beautiful hand-woven wiring loom…):

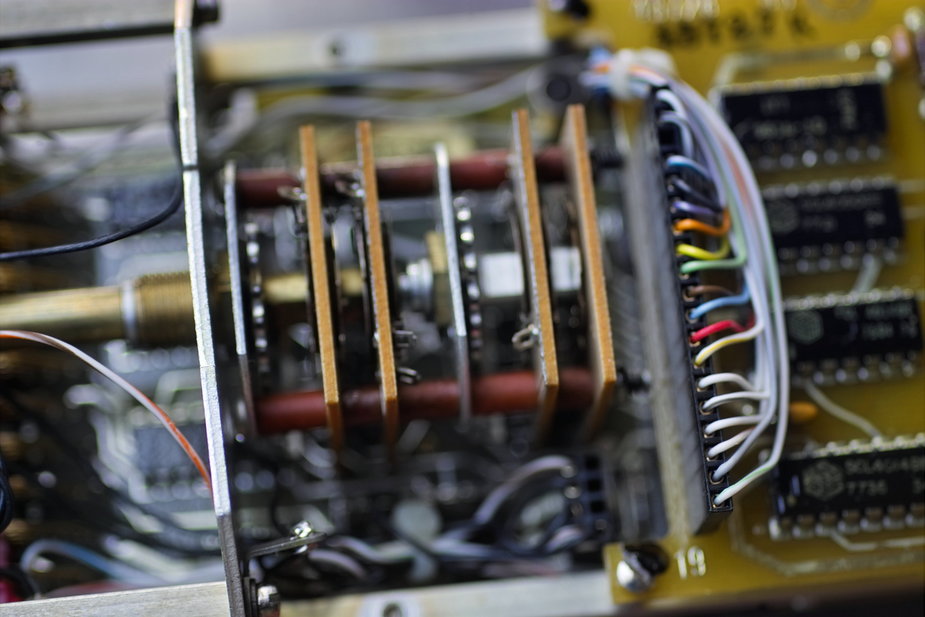

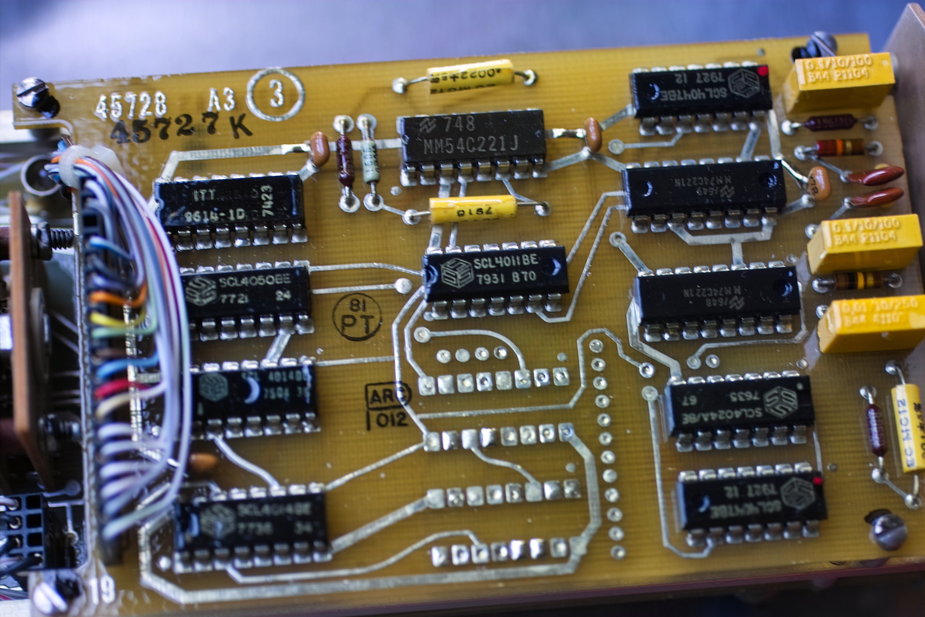

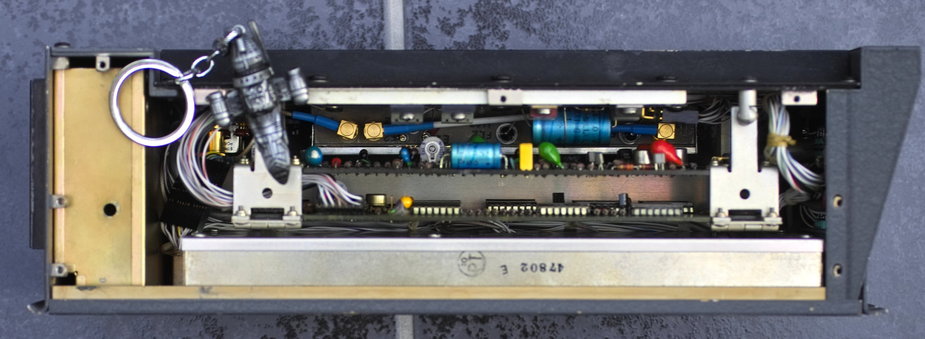

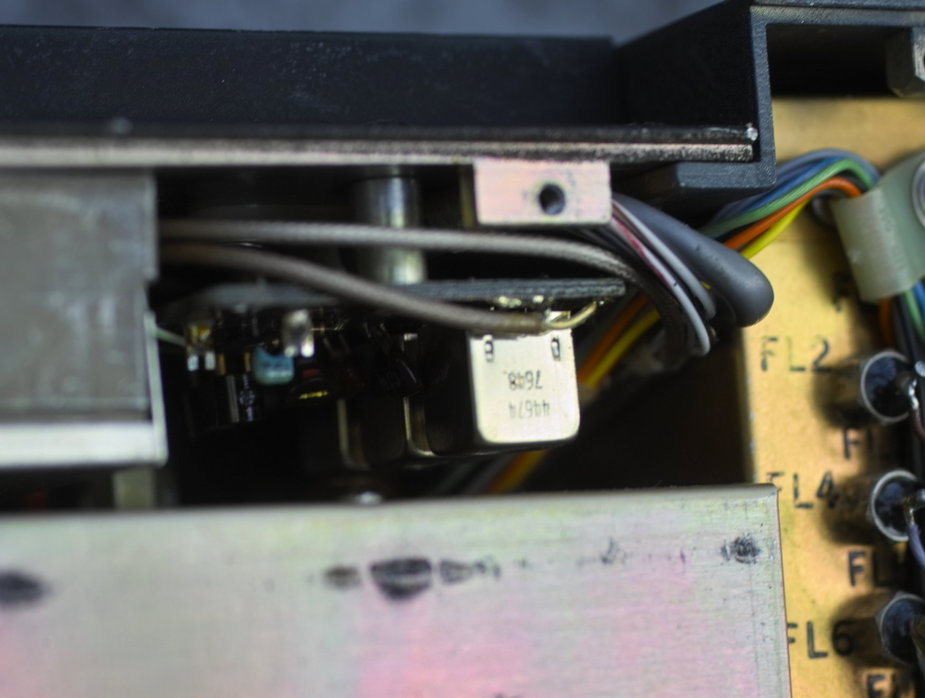

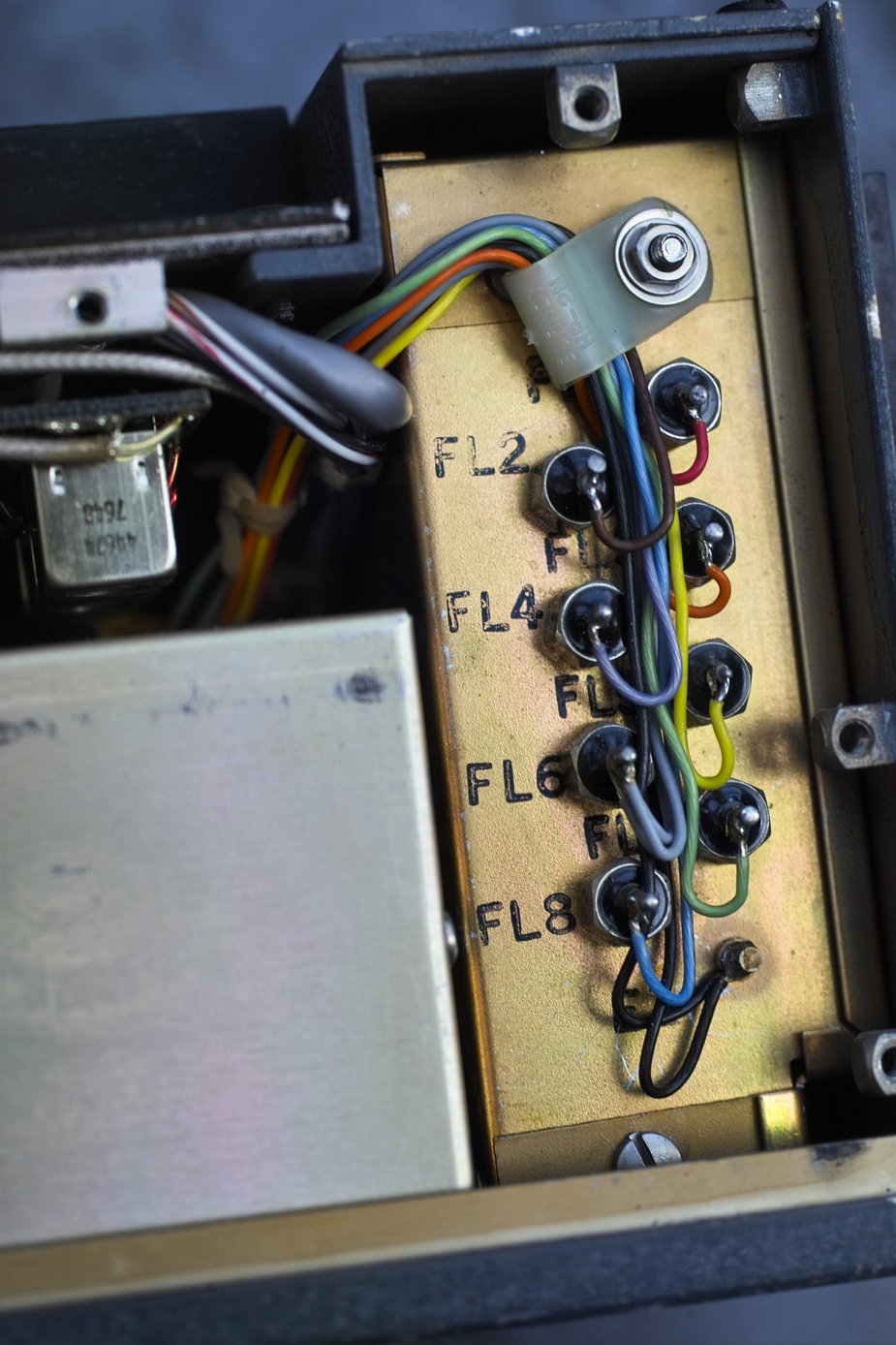

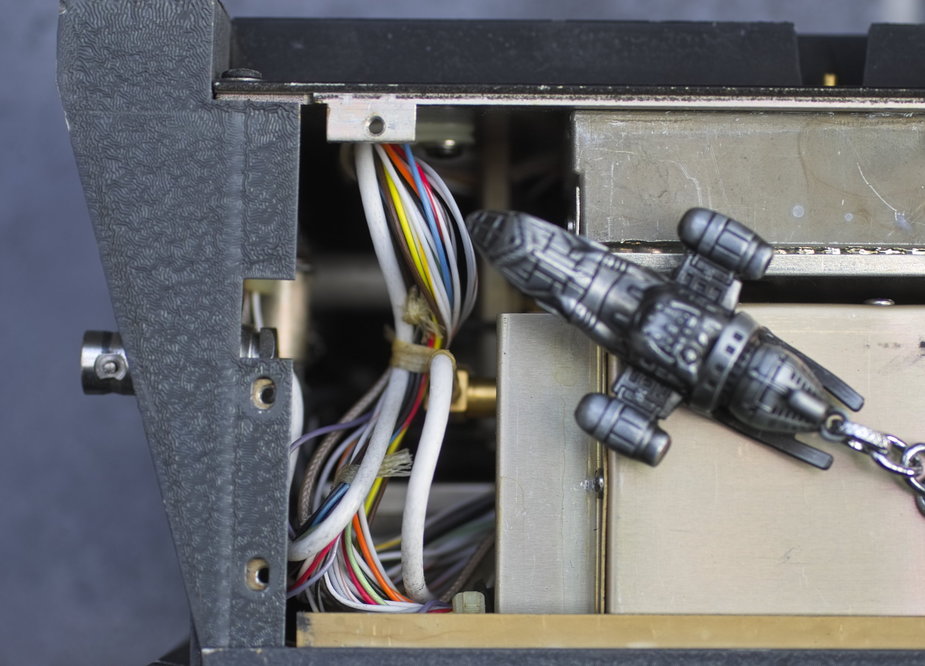

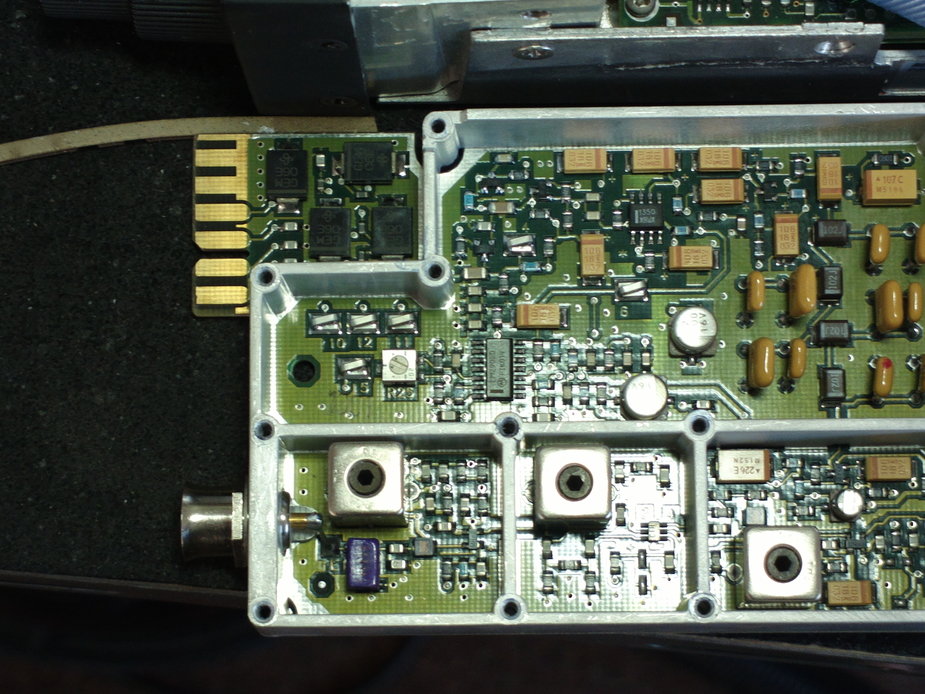

And this is the big box for the avionics rack with all the power electronics and high frequency circuits. The keyring I placed there for comparison is 7cm long:

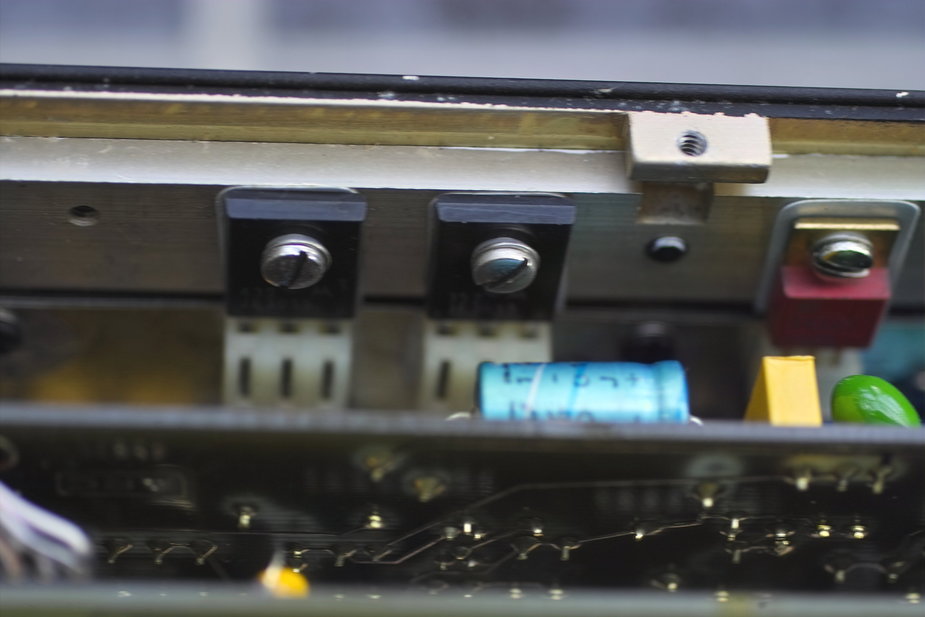

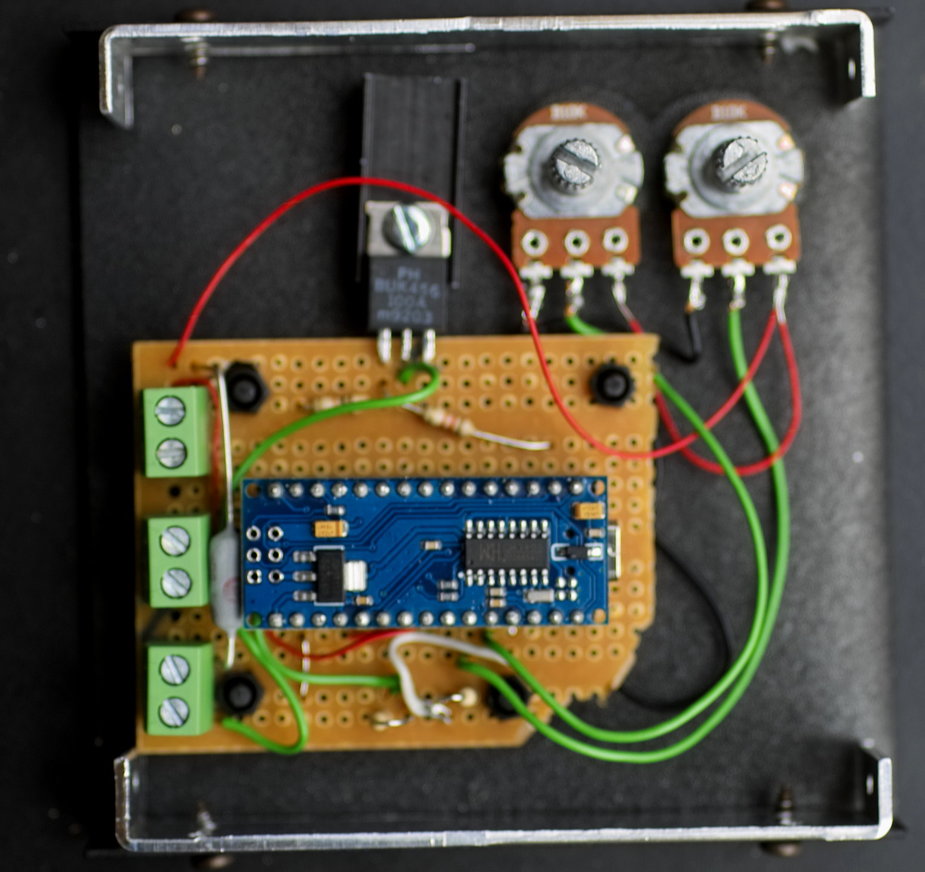

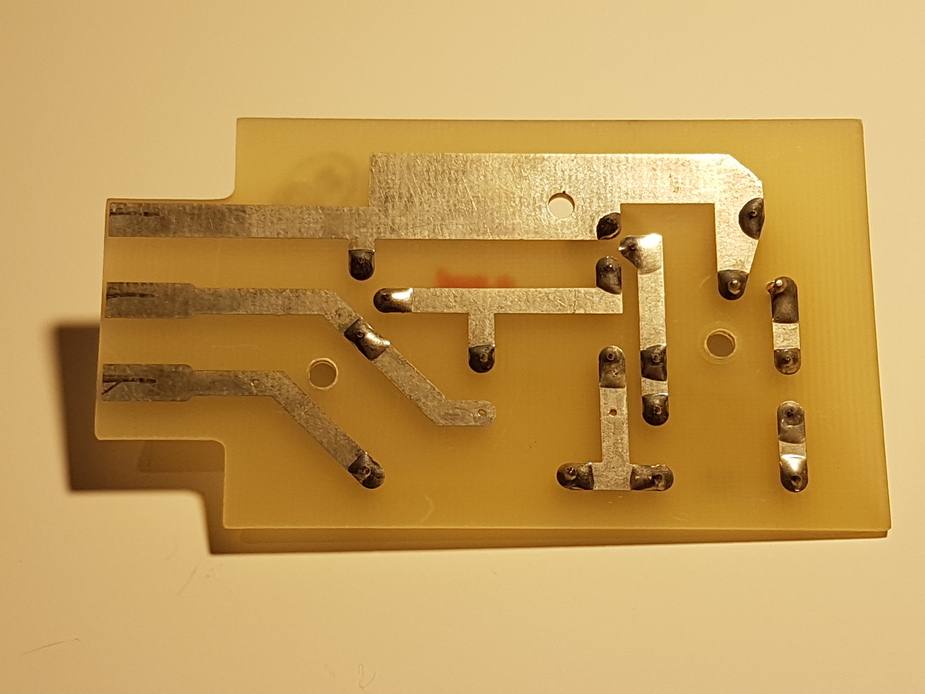

And last comes a piece of tinkerer’s avionics from 2016  I was fed up with constantly replacing dozens of soldered mini-lightbulbs in the panel of “my” FTO’s FNPT and replaced them all with LEDs recently. In order to be able to dim them (the original bulbs get an analog voltage of 0 – 15V) I made this little box containing essentially a microcontroller which measures the voltage and a power MOSFET that feeds a pulsed current to the LEDs. The potentiometers are for adjusting the min. and max. brightness to the remaining instruments on the panel.

I was fed up with constantly replacing dozens of soldered mini-lightbulbs in the panel of “my” FTO’s FNPT and replaced them all with LEDs recently. In order to be able to dim them (the original bulbs get an analog voltage of 0 – 15V) I made this little box containing essentially a microcontroller which measures the voltage and a power MOSFET that feeds a pulsed current to the LEDs. The potentiometers are for adjusting the min. and max. brightness to the remaining instruments on the panel.

The PCB is missing a corner but this does not affect the function…

Jesse wrote:

Trig is more expensive then the others

I found them to be very reasonable here. UK£ 1025 is hard to beat by anyone. But the website also say this:

“TRIG AVIONICS increased their prices right across the product range post BREXIT. At this time we have good stocks on both the TT21 Transponder and TY91 Transceiver at pre Brexit prices until current stocks are sold out.”

And of course further up is the worst thing:

“AIRWORLD UK – THE END OF AN ERA

For many the end of October is close to the end of the flying season, but for our team at Airworld UK it is the end of an era.

Ann and I have decided that Airworld UK will close at the end of October.”

So those looking for a reasonable priced Trig radio and transponder have to hurry.

Jan_Olieslagers wrote:

Trig are very good, that’s why I bought their gear, and will again. But they’re not the only ones.

For me they are pretty much the only ones that have a form factor that fits (head in the panel and the body mounted on the wall). MGL would also fit, but the authority would not allow it.

Hmm, I thought for a second to post some pictures of the internals of my MGL EFIS. But with you people pointing out all the bad soldering and bad design choices, I think I will live a happier life not knowing

You should post it. It is always interesting to see current stuff.

OK, I am just too curious to not look “inside” stuff  but this electronic stuff all look like personal computer internals to me.

but this electronic stuff all look like personal computer internals to me.

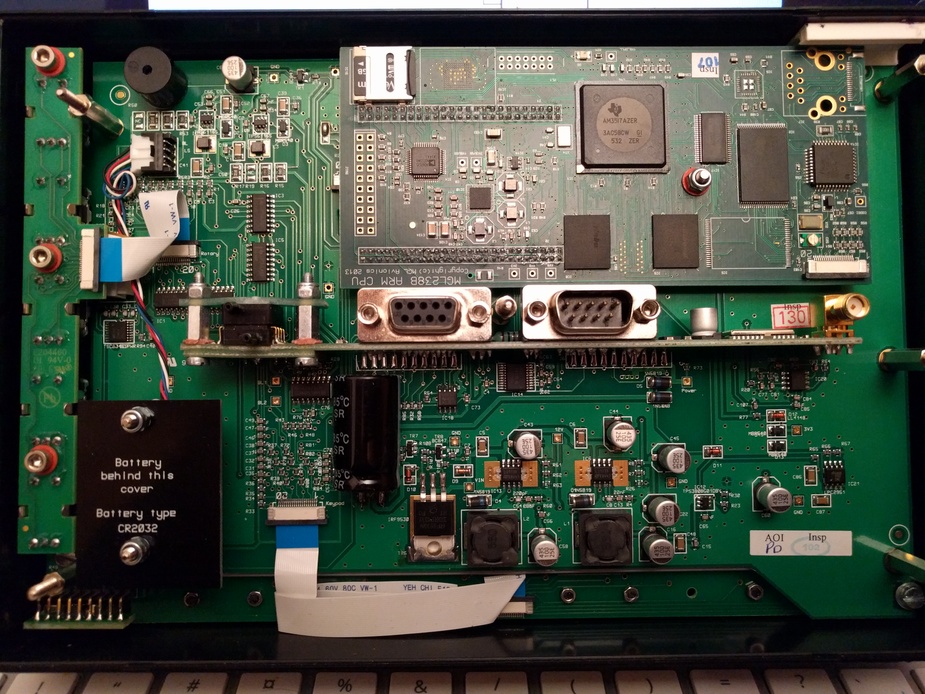

This is the MGL iEFIS Explorer Lite. The “lite” is the all in one package

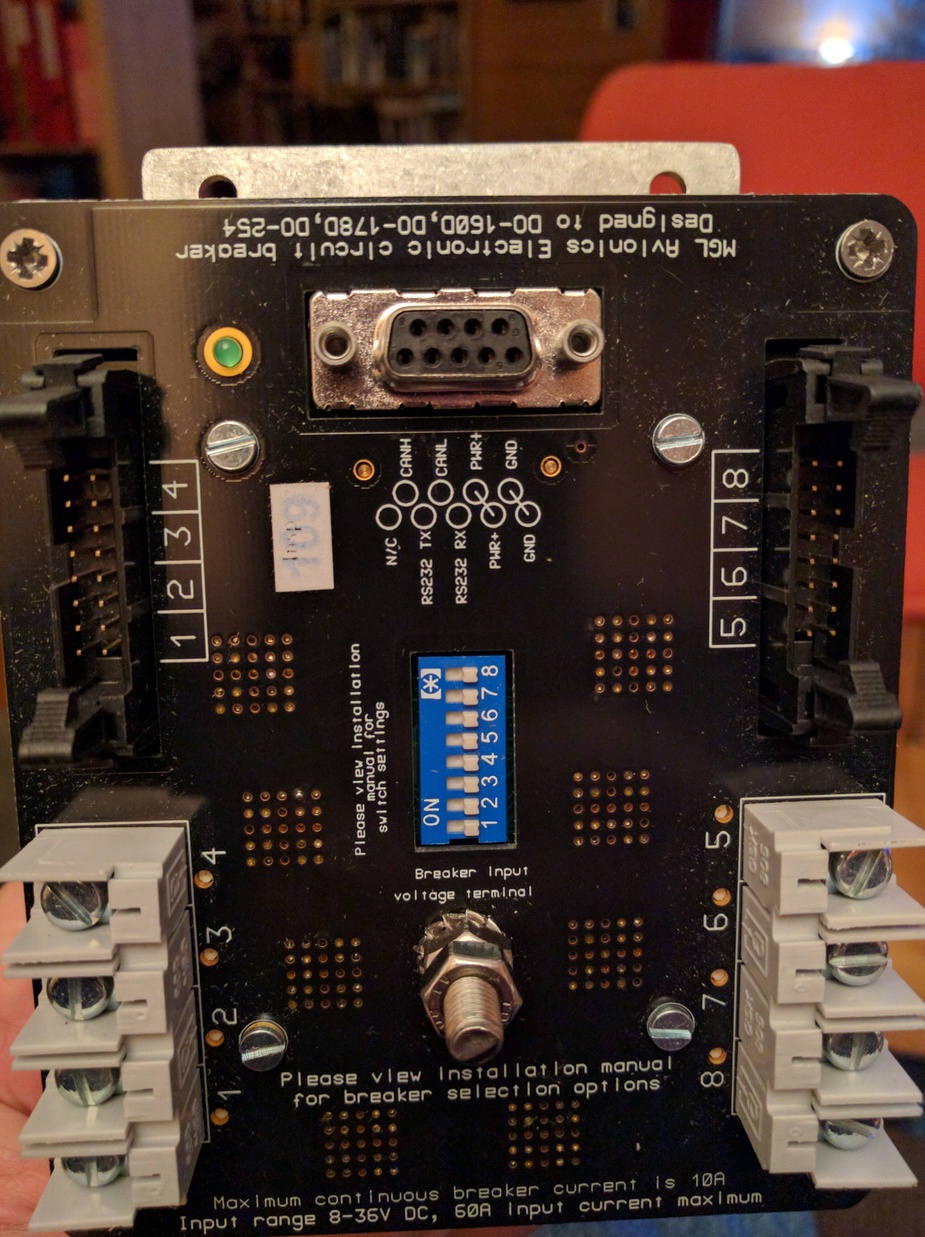

Here is the electronic circuit breakers.

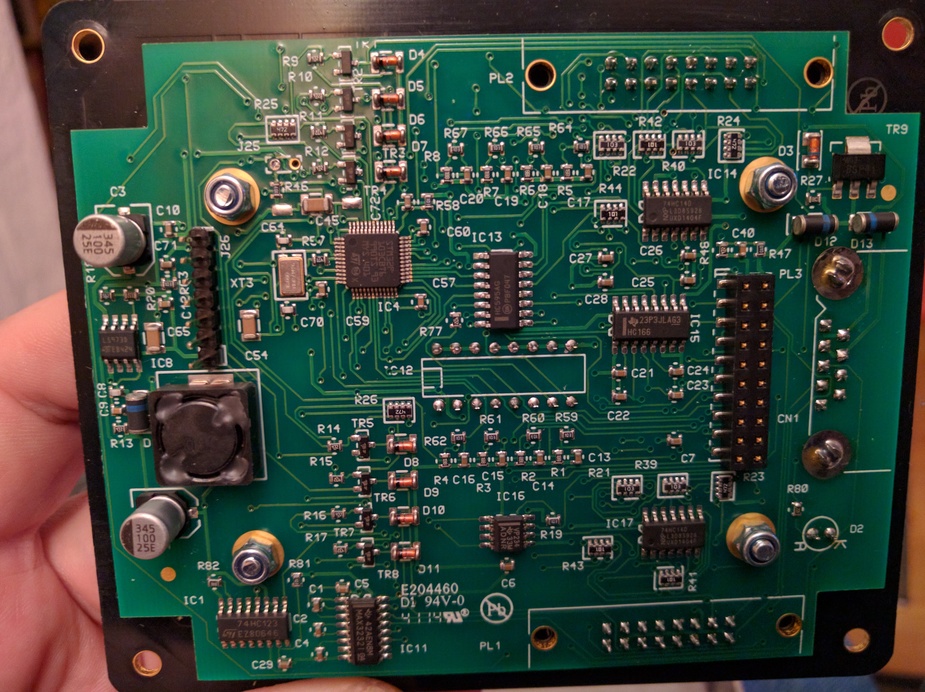

Then the ASX-1, my “backup” alt and ASI (in case the EFIS goes black, but still need battery). This one actually looks a bit cool inside.

That stuff is well made. Nice and modern construction, nearly all SMT.

Thanks for posting that.

The MGL is not a PC; it appears to be all custom stuff.

The only negative comment I would make is on the inter-PCB connections which are often hard-soldered and suspectible to vibration. This is really clear on the last pic above. However it will be fine if the PCBs are well supported by the case of the instrument.

Peter wrote:

That stuff is well made. Nice and modern construction, nearly all SMT.

Wouldn’t get near to passing the test specs for modern automotive electronics. To be fair it probably doesn’t need to.

Wouldn’t get near to passing the test specs for modern automotive electronics

In what respect?

KX165A/8.33:

The glideslope receiver

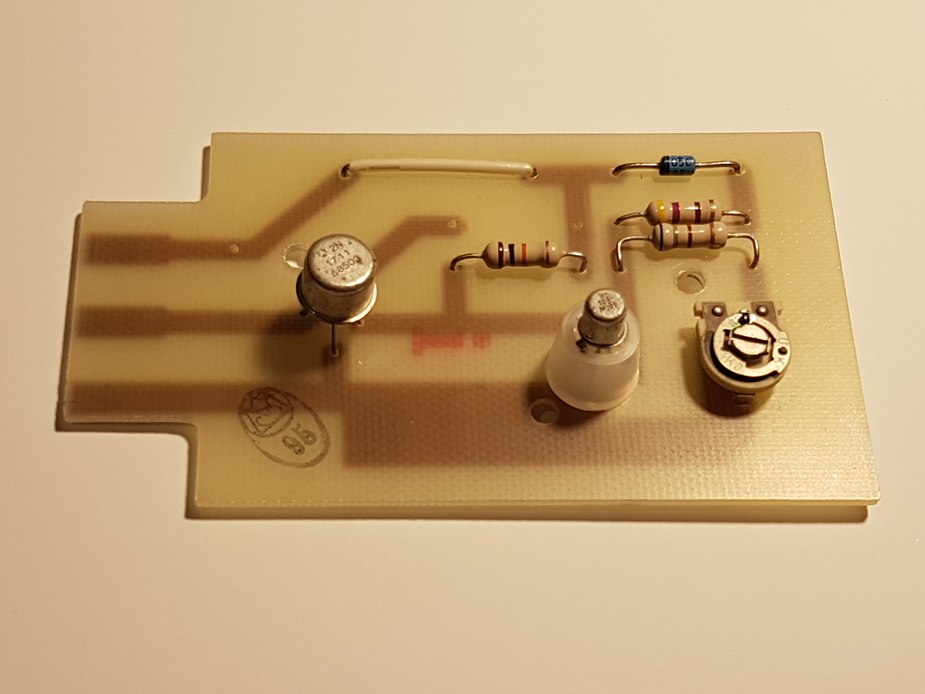

Does anyone know what this is? I believe it came out of a TB10… The TO5 transistor is a 2N1711 with a 1985 datecode. The TO18 one is a good old BC108C  The diode is a 12V zener.

The diode is a 12V zener.

I wonder if it is something to do with instrument backlight dimming? But the transistor cannot possibly be dissipating much power.

The construction is typical of Socata and some very low volume production in a wooden shed. The connector fingers are not even gold flashed…